Sponge material for preparing yellowing-resistant cotton pad and preparation method thereof

A sponge and yellowing-resistant technology is applied in the preparation of sponge materials for yellowing-resistant cotton and its preparation field, and can solve the problems of accelerated material oxidation process, yellowing resistance, unsatisfactory VOC emission, discoloration of white materials, etc. Achieve the effect of low VOC emission, excellent yellowing resistance and excellent water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

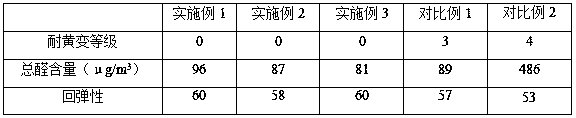

Examples

Embodiment 1

[0028] Ethylene oxide-propylene oxide-ethylene oxide block polyether polyol: the mass percentage of ethylene oxide in epoxide is 88%, the mass of terminal ethylene oxide in ethylene oxide The percentage content is 30%, the mass percentage content of the primary hydroxyl group in the terminal hydroxyl group is 85%, the number average molecular weight is 1000, the average functionality is 2.5, and the total aldehyde content is 1 μg / g. The preparation method of ethylene oxide-propylene oxide-ethylene oxide block polyether polyol is as follows: add the initiator (a mixture of glycerol and dipropylene glycol) and the catalyst KOH into the reactor, raise the temperature to 120°C, Remove water under the condition of vacuum degree of -0.095MPa until the water content is less than 0.05%, turn off the vacuum, put ethylene oxide, propylene oxide, and ethylene oxide into the reaction kettle in proportion, and the reaction temperature is 110- 120°C, reaction pressure ≤ 0.04MPa, to obtain c...

Embodiment 2

[0033] Polyurethane resin component: Add 100g propylene oxide-ethylene oxide block polyether polyol (purchased from Jiangsu Zhongshan Chemical Co., Ltd., the mass percentage content of ethylene oxide in the epoxide is 80 %, the mass percent content of the primary hydroxyl group in the terminal hydroxyl group is 90%, the number average molecular weight is 2000, the average functionality is 2.8, and the total aldehyde content is 0.3 μ g / g. The initiator used in the preparation is the mixture of glycerol and dipropylene glycol .), heated up to 120°C, dehydrated at 120°C and a vacuum of -0.095MPa for 2 hours, cooled to 45°C, added 33g of hexamethylene diisocyanate, stirred for 30 minutes, and raised to 110°C (heating time is 20min), then react at 110°C for 2 hours, cool down to 50°C to obtain a polyurethane resin component, and store in a nitrogen seal. After testing, the mass percentage of -NCO in the polyurethane resin component was 8%.

[0034] Foaming agent components: Weigh ...

Embodiment 3

[0037]Polyurethane resin component: Add 100g propylene oxide-ethylene oxide block polyether polyol (purchased from Jiangsu Zhongshan Chemical Co., Ltd., the mass percentage of ethylene oxide in the epoxide is 70 %, the mass percent content of the primary hydroxyl group in the terminal hydroxyl group is 85%, the number average molecular weight is 1500, the functionality is 2, and the total aldehyde content is 0.5 μ g / g. The initiator used in the preparation process is dipropylene glycol.), heating up to 120°C, dehydrate for 2 hours at 120°C and a vacuum of -0.095MPa, cool down to 48°C, add 48g of isophorone diisocyanate, stir for 30 minutes, raise the temperature to 95°C (heating time is 10min), at 95°C The reaction was carried out at ℃ for 1 hour, and then the temperature was lowered to 50 ℃ to obtain a polyurethane resin component, which was stored in a nitrogen seal. After testing, the mass percentage of -NCO in the polyurethane resin component was 8.5%.

[0038] Foaming ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com