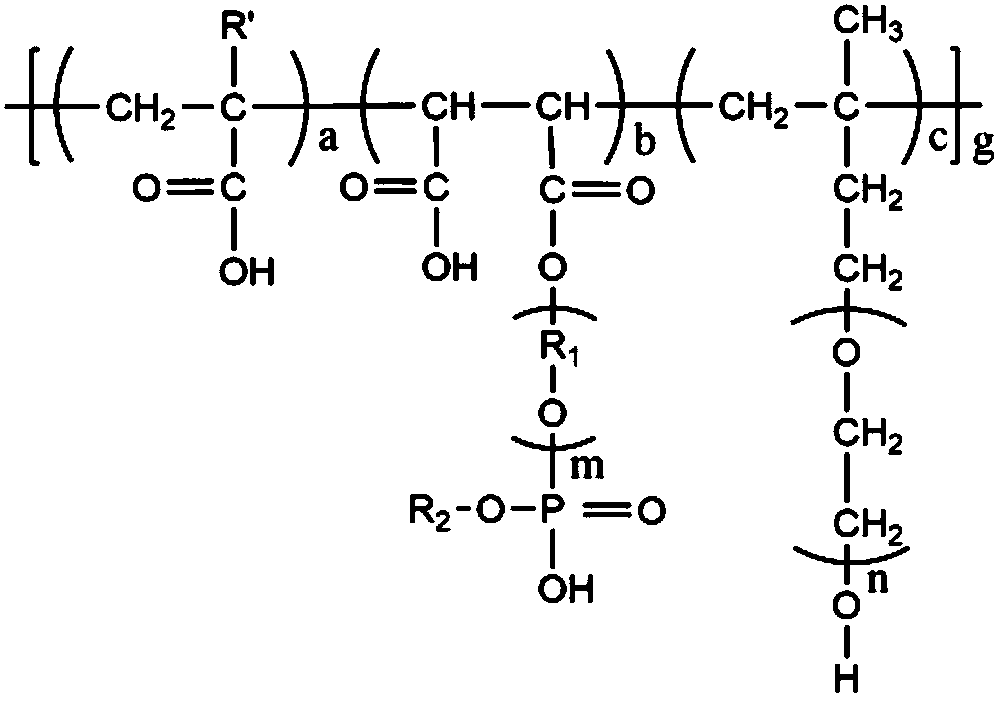

Viscosity-reducing type polycarboxylic acid water reducing agent for high-strength concrete and preparation method of viscosity-reducing type polycarboxylic acid water reducing agent

A viscous polycarboxylate and high-strength concrete technology, which is applied in the field of water reducing agent, can solve the problems of concrete viscosity increase, achieve the effect of improving water retention, improving workability, and helping to reduce viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

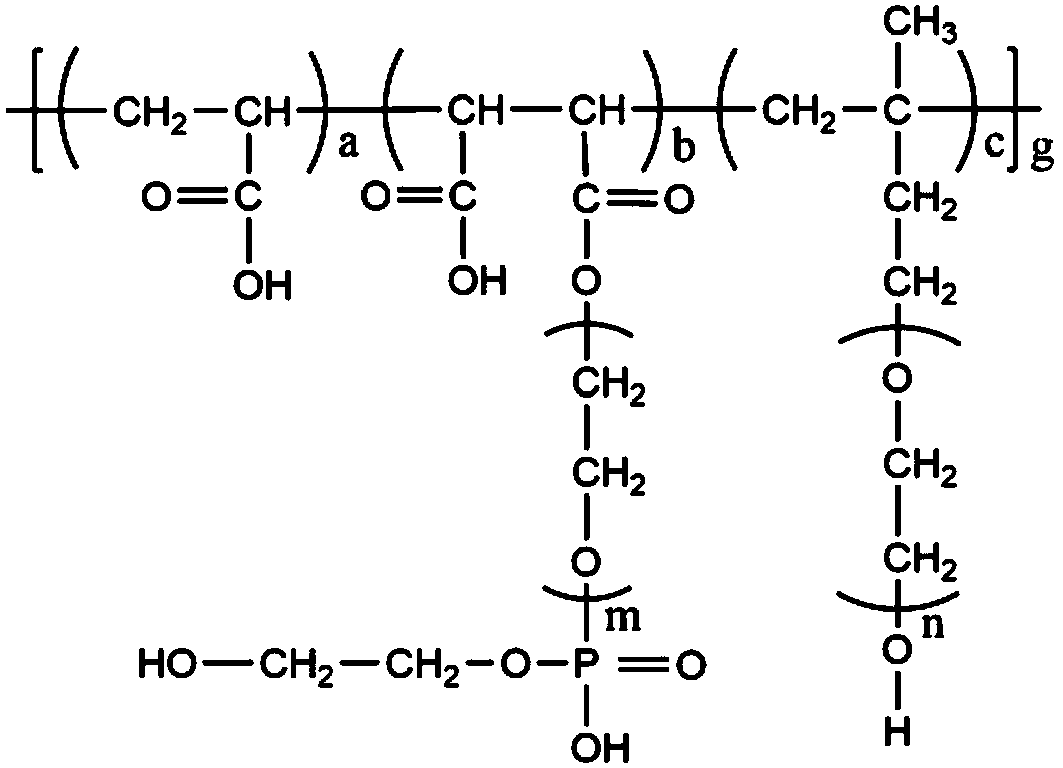

[0034] The viscosity-reducing polycarboxylate superplasticizer for high-strength concrete in this example uses maleic anhydride modified phosphate, unsaturated carboxylic acid and isopentenol polyoxyethylene ether as the main raw materials, and acts as an initiator and a chain transfer agent. , formed by free radical polymerization. Specific steps are as follows:

[0035](1) Preparation of maleic anhydride-modified phosphate ester: 0.1mol of polyethylene glycol with a molecular weight of 400 is placed in a reaction vessel, and 0.1mol of maleic anhydride and 0.3% of the total mass of raw materials are added at one time under stirring conditions. The p-toluenesulfonic acid was stirred and reacted at 55°C for 3h. Then add 0.02mol of P in batches within 20min 2 o 5 , and continued stirring at 70°C for 2h. Continue to add 0.04 mol of ethylene glycol dropwise within 30 minutes, and keep the temperature for 1 hour under stirring condition to prepare maleic anhydride-modified phos...

Embodiment 2

[0041] The viscosity-reducing polycarboxylate superplasticizer for high-strength concrete in this example uses maleic anhydride modified phosphate, unsaturated carboxylic acid and isopentenol polyoxyethylene ether as the main raw materials, and acts as an initiator and a chain transfer agent. , formed by free radical polymerization. Specific steps are as follows:

[0042] (1) The preparation of maleic anhydride modified phosphoric acid ester is the same as in Example 1.

[0043] (2) Preparation of viscosity-reducing polycarboxylate water reducer: Weigh 10g (4.4%) of maleic anhydride modified phosphate, 200g (87.7%) of isopentenol polyoxyethylene ether with a molecular weight of 2400 and 150g Add water into a reaction vessel that excludes air, stir and dissolve at room temperature, and use it as a base material. 15g (6.6%) methacrylic acid and 17.5g water are formulated into material A, 0.7g (0.3%) mercaptoethanol, 0.25g vitamin C (0.1%) and 15g water are formulated into mate...

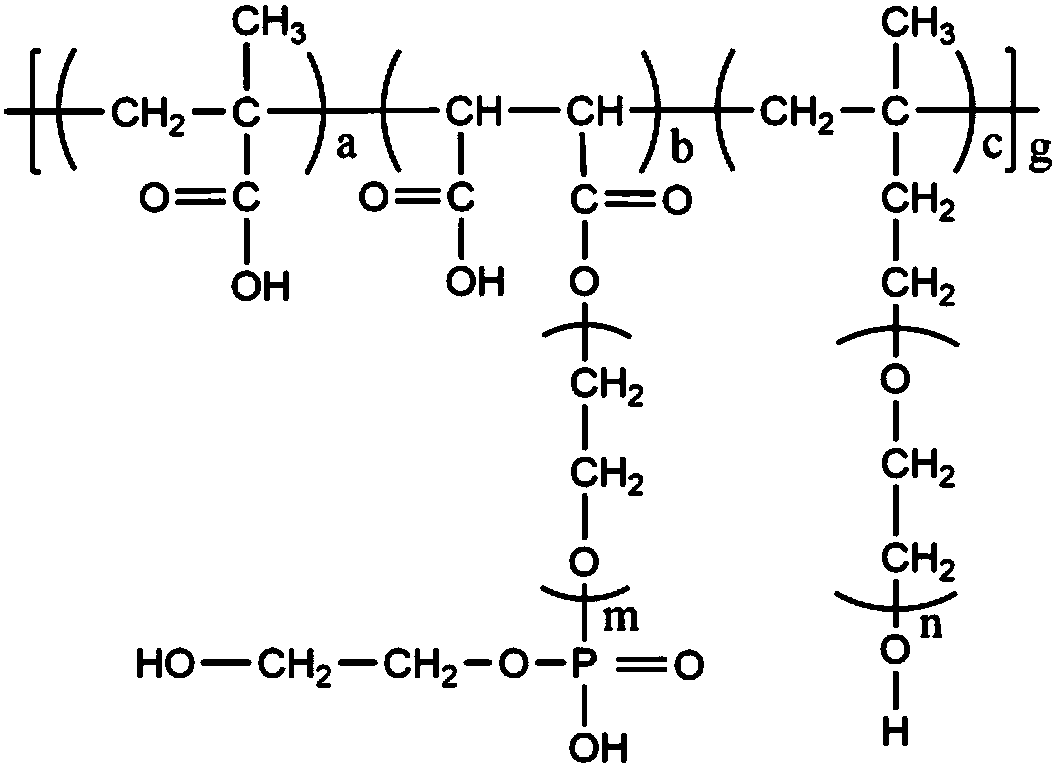

Embodiment 3

[0048] The viscosity-reducing polycarboxylate superplasticizer for high-strength concrete in this example uses maleic anhydride modified phosphate, unsaturated carboxylic acid and isopentenol polyoxyethylene ether as the main raw materials, and acts as an initiator and a chain transfer agent. , formed by free radical polymerization. Specific steps are as follows:

[0049] (1) Preparation of maleic anhydride-modified phosphate ester: put 0.1 mol of polypropylene glycol with a molecular weight of 1000 in a reaction vessel, heat up to 50°C to fully dissolve, and add 0.1 mol of maleic anhydride at one time under stirring conditions and concentrated sulfuric acid with a mass percentage of 0.2%, stirred and reacted at 60° C. for 2.5 h. Then add 0.03mol of P in batches within 30min 2 o 5 , and continued stirring at 70°C for 2.5h. Continue to add 0.06 mol of diethanolamine dropwise within 25 minutes, and keep the temperature for 1.5 hours under the condition of stirring, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com