Small organic molecule luminescent material ink and preparation method thereof

A luminescent material and small molecule technology, applied in the field of inkjet printing, can solve problems affecting device performance and prone to phase separation, and achieve the effects of improving thickness uniformity, inhibiting dewetting, and increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing the above-mentioned organic small molecule luminescent material ink, comprising the following steps:

[0044] A) after mixing the solute with the first solvent, a mixed solution is obtained;

[0045] B) Adding the second solvent into the mixed solution and mixing to obtain the organic small molecule luminescent material ink.

[0046] Specifically, according to the formula, first weigh the solute and put it in the container, then weigh the first solvent and add it to the container to form a mixed solution, then weigh the second solvent and put it into the above mixed solution to stir. After completely dissolving, the organic Small molecule luminescent material ink.

[0047] Wherein, the mixing temperature of the second solvent and the mixed solution is 20-60°C, preferably at room temperature, and in the present invention, the room temperature is defined as 25±5°C.

[0048] The invention provides an ink for impr...

Embodiment 1

[0051] Weigh 1.92 mg of H2 and place it in the container, then weigh 0.58 mg of Ir(mppy)3 and place it in the container, then weigh 0.6 milliliters of cyclohexanone and add it to the container to form a mixed solution, then weigh 0.4 milliliters of cyclohexyl Benzene is put into the above mixed solution, stirred at room temperature, and after being completely dissolved, an organic small molecule luminescent material solution is obtained that uses a triple line fixing solvent to improve the film-forming properties of the printed organic small molecule luminescent material and a blending solvent to improve the uniformity of the film .

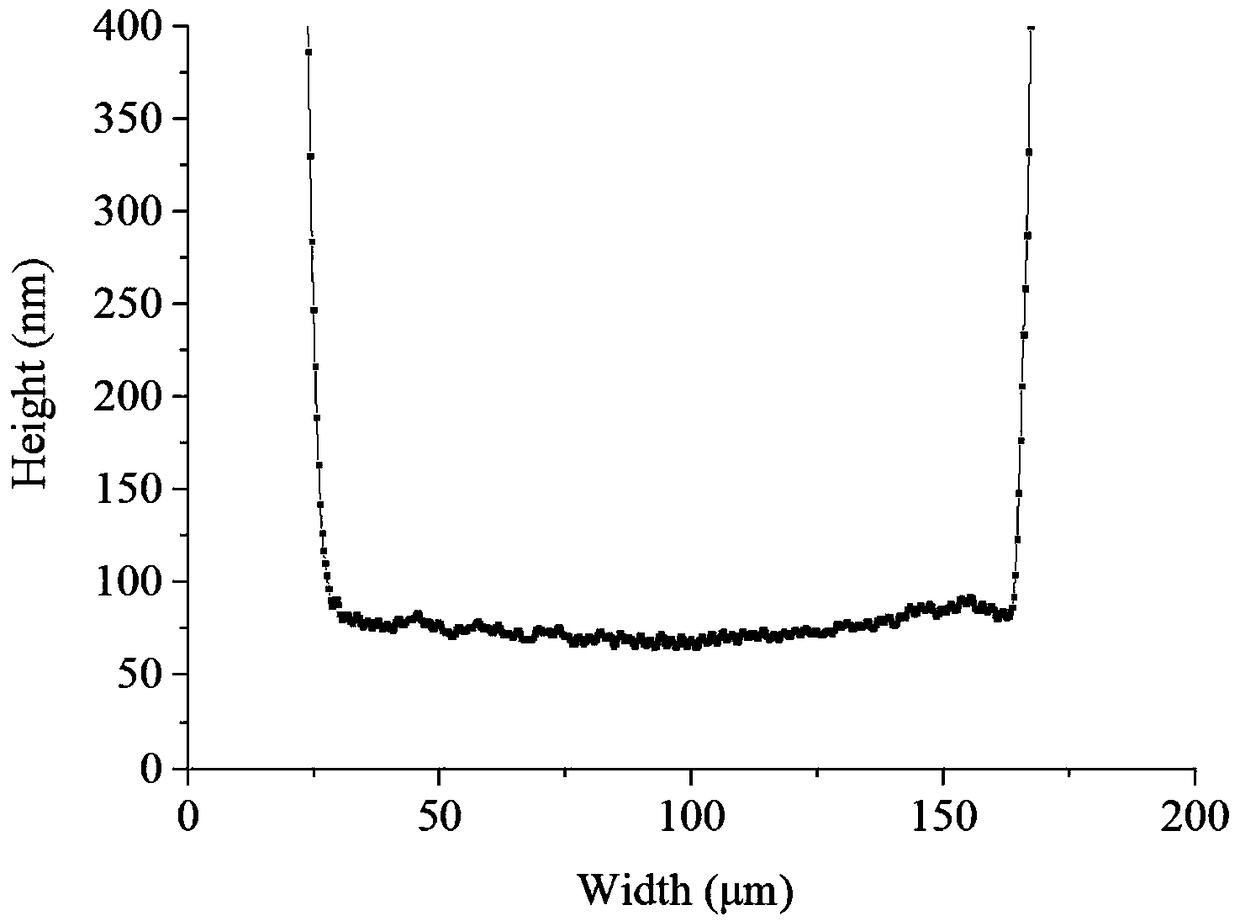

[0052] figure 1 It is H2 in embodiment 1: Ir (mppy) 3 solution inkjet printing is deposited in the H2 in the confinement channel: Ir (mppy) 3 The optical micrograph of thin film, figure 2 Is H2 in embodiment 1: Ir (mppy) 3 solution inkjet printing is deposited into the H2 in the confinement trench: Ir (mppy) The cross-sectional height map of th...

Embodiment 2

[0054] Weigh 1.2 mg of H2 and place it in the container, then weigh 0.3 mg of Ir(mppy)3 and place it in the container, then weigh 0.6 milliliters of acetophenone and add it to the container to form a mixed solution, then weigh 0.4 milliliters of dichloro Benzene is put into the above mixed solution, stirred at room temperature, and after being completely dissolved, an organic small molecule luminescent material solution is obtained that uses a triple line fixing solvent to improve the film-forming properties of the printed organic small molecule luminescent material and a blending solvent to improve the uniformity of the film .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com