Preparation method of metal doped fluorescent carbon quantum dot

A technology of carbon quantum dots and metal doping, which is applied in fluorescence/phosphorescence, chemical instruments and methods, preparations for in vivo experiments, etc., and can solve problems such as strong application limitations, less metal doping, and high cytotoxicity , to achieve high doping rate and yield, simple synthesis method and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

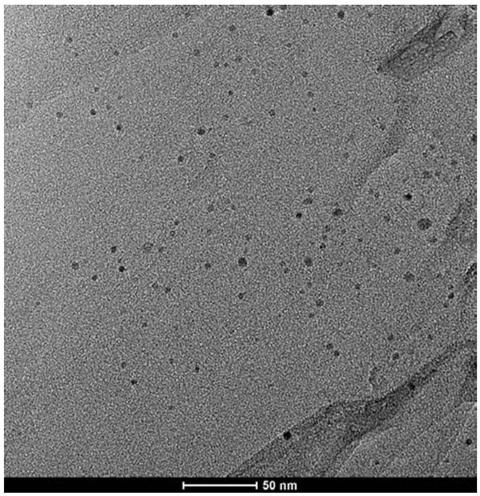

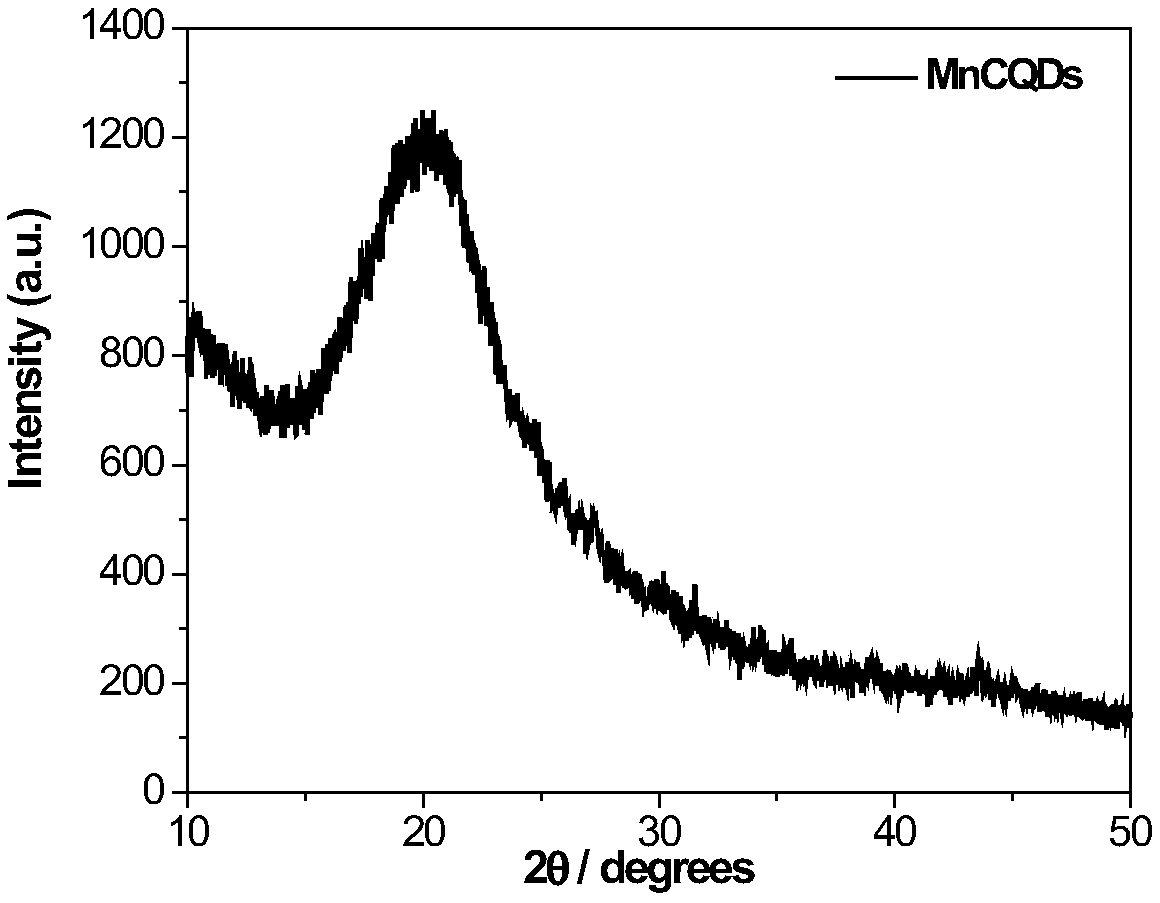

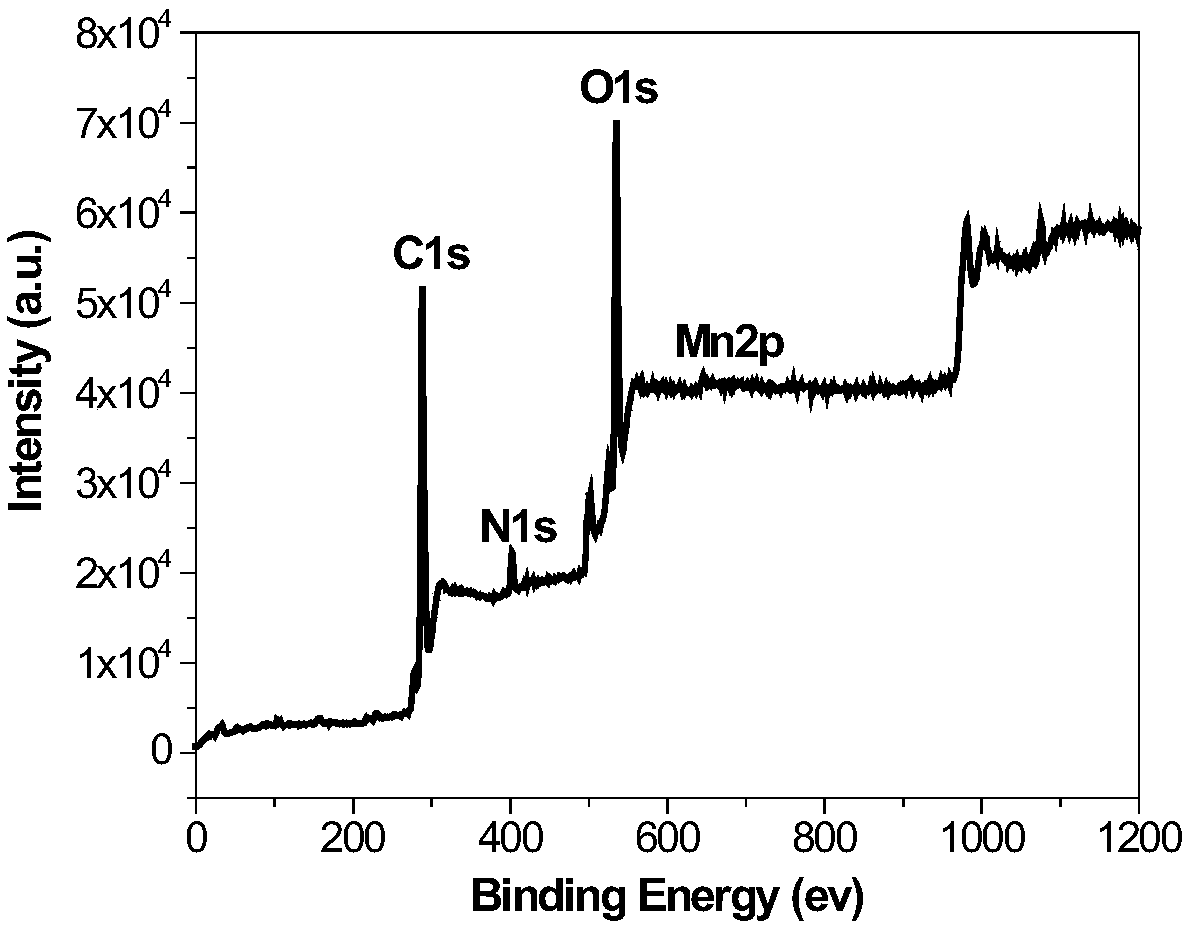

[0039] A method for preparing metal-doped fluorescent carbon quantum dots, which specifically comprises the following steps:

[0040] 1) Dissolve 10 mg of tetraphenylmanganese porphyrin (MnTPP) in 4 mL of tetrahydrofuran to obtain liquid A. At this time, the mass concentration of tetraphenyl manganese porphyrin (MnTPP) in THF is 2.5 mg / mL;

[0041] 2) Dissolve 2 g of citric acid in 40 mL of water to obtain liquid B. At this time, the mass concentration of citric acid in water is 50 mg / mL;

[0042] 3) Mix liquid A and liquid B, and perform ultrasonic dispersion to obtain mixed liquid C, wherein the volume ratio of tetrahydrofuran in liquid A to water in liquid B is 1:10, and the dispersion time of ultrasonic dispersion is 20 minutes;

[0043] 4) Put the mixed solution C in an oil bath at 180°C for heating in an oil bath. After the mixed solution C becomes viscous, add 3 mL of water and continue the reaction. Repeat this process 5 times to obtain the reaction solution D;

[004...

Embodiment 2

[0046] The difference between this example and Example 1 is that the metalloporphyrin compound is tetraphenyl zinc porphyrin (ZnTPP).

Embodiment 3

[0048] The difference between this example and Example 1 is that the metalloporphyrin compound is tetraphenylcopper porphyrin (CuTPP).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com