Application of zirconium-doped niobium oxyphosphate catalyst in preparation of carbon quantum dots from lignin, preparation method of carbon quantum dots and carbon quantum dots

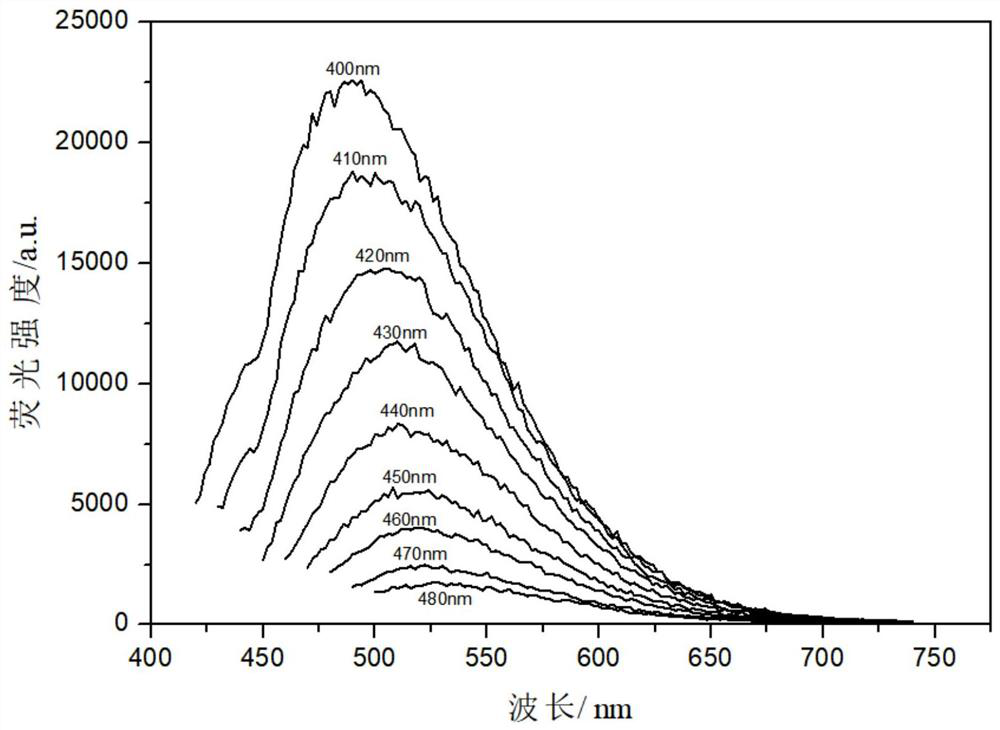

A technology of niobium oxyphosphate catalyst and carbon quantum dots, applied in heterogeneous catalyst chemical elements, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as environmental pollution and cumbersome processes , to achieve the effect of simple preparation route, strong fluorescence emission and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also relates to a method for preparing carbon quantum dots, comprising the following steps:

[0042] Mix lignin, zirconium-doped niobium oxyphosphate catalyst, organic amine reagent and deionized water to obtain the second mixed solution, then perform high-temperature hydrothermal treatment in an inert gas atmosphere, and freeze-dry the crude product after high-temperature hydrothermal treatment to obtain carbon Quantum dots, the specific surface area of the zirconium-doped niobium oxyphosphate catalyst is 50-250m 2 / g, and the amount of strong surface acid at the pyridine desorption temperature>400°C>100μmol / g.

[0043] Specifically, the lignin includes at least one of alkali lignin, kraft lignin, lignosulfonate and enzymatic lignin.

[0044] Specifically, in the zirconium-doped niobium oxyphosphate catalyst, the doping amount of zirconium is 1wt%-10wt%.

[0045] Specifically, the organic amine reagent includes at least one of ethylenediamine,...

Embodiment 1-11

[0053] Embodiment 1-11 relates to a kind of method for preparing carbon quantum dots by lignin, comprises the following steps:

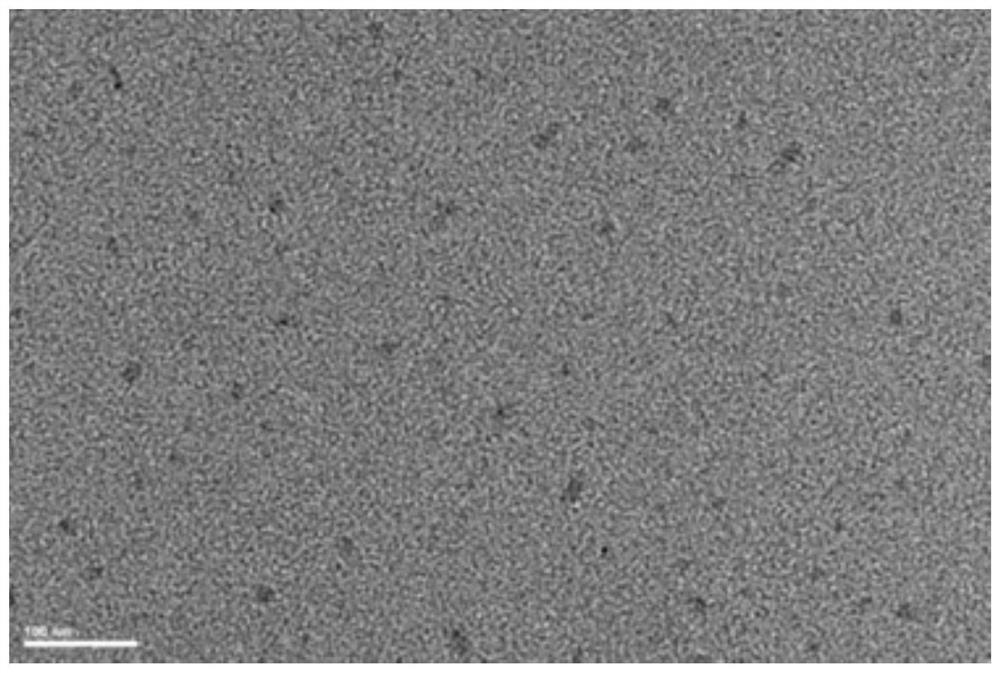

[0054] Dissolve the lignin and zirconium-doped niobium oxyphosphate catalyst in an organic amine reagent and 30 mL of deionized water, and perform ultrasonic treatment to obtain the second mixed solution. Stir the second mixed solution evenly and transfer it to a high-pressure reactor. Under the protection of nitrogen, high-temperature hydrothermal treatment, and then naturally cooled to room temperature, the reacted mixed solution was filtered through a 0.22 μm microporous membrane to remove insoluble carbon, and then the filtrate was transferred to a dialysis bag with a molecular weight of 3000Da for dialysis for 72 hours. Replace deionized water, obtain carbon quantum dots after dialysis purification and freeze drying.

[0055] The concrete process parameter of embodiment 1-11 is as shown in table 1.

[0056] Table 1. The concrete process paramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com