A kind of water-based surface treatment agent for synthetic leather and preparation method thereof

A surface treatment agent and synthetic leather technology, which is applied in the field of water-based polyurethane, can solve the problems of single function and inability to meet the requirements of synthetic leather's anti-ultraviolet ability, so as to improve compatibility, improve anti-ultraviolet ability, and improve heat resistance stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A water-based surface treatment agent for synthetic leather, comprising the following components by weight:

[0056] 100 parts of water-based polyurethane;

[0057] 0.4 part of polydimethylsiloxane;

[0058] 0.4 parts of defoamer, water-based defoamer, model DF-572, purchased from Dongguan Defeng Defoamer Co., Ltd.;

[0059] 1 part of thickener is carboxymethyl cellulose;

[0060] 1 part of organosilicon hand feeling agent, model HF-647, purchased from Guangzhou McGee Polymer Material Co., Ltd.;

[0061] 3 parts of matting agent, kaolin with a particle size of 0.45 μm;

[0062] 4 parts of anti-ultraviolet particles;

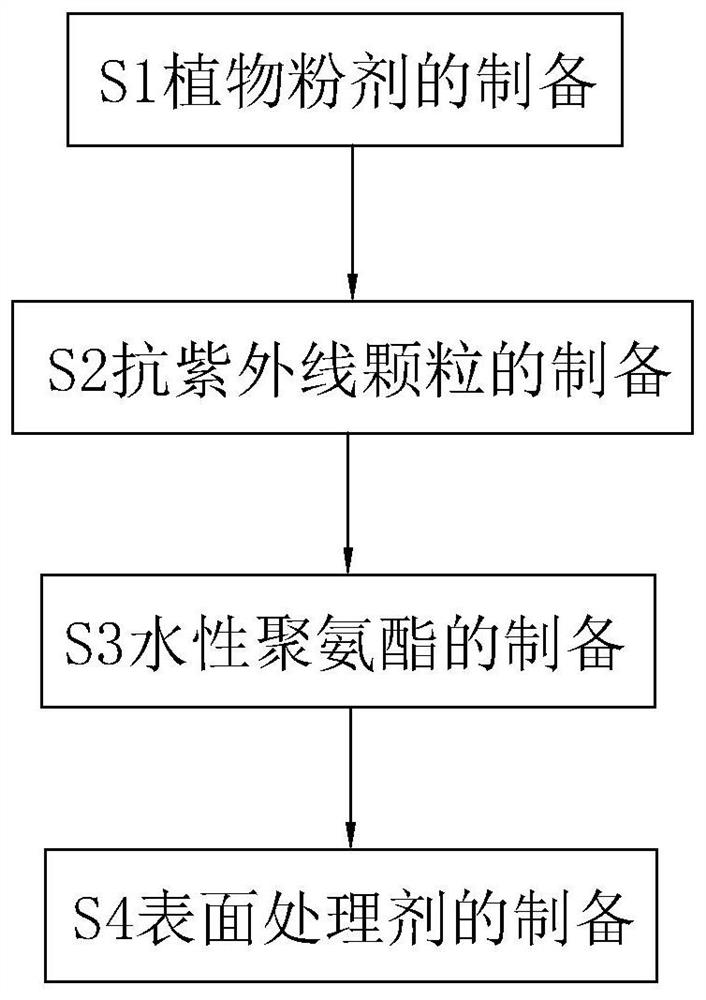

[0064] A kind of preparation method of water-based surface treatment agent for synthetic leather, such as figure 1 As shown, including the following process:

[0065] The preparation of S1 plant powder, the preparation process of plant powder is as follows:

[0066] 1. Pick fresh kaeba and aloe vera, wash the kaeba ro...

Embodiment 2

[0086] A water-based surface treatment agent for synthetic leather, comprising the following components by weight:

[0087] 120 parts of water-based polyurethane;

[0088] 0.8 part of polydimethylsiloxane;

[0089] 0.8 parts of defoamer, water-based defoamer, model DF-572, purchased from Dongguan Defeng Defoamer Co., Ltd.;

[0090] 2 parts of thickener is carboxymethyl cellulose;

[0091] 3 parts of organosilicon hand feeling agent, model HF-647, purchased from Guangzhou Maiji Polymer Material Co., Ltd.;

[0092] 7 parts of matting agent, kaolin with a particle size of 0.45 μm;

[0093] 6 parts of anti-ultraviolet particles;

[0094] Plant powder 5 parts.

[0095] A kind of preparation method of water-based surface treatment agent for synthetic leather, such as figure 1 As shown, including the following process:

[0096] The preparation of S1 plant powder, the preparation process of plant powder is as follows:

[0097] 1. Pick fresh kaeba and aloe vera, wash the kaeba ...

Embodiment 3

[0117] A water-based surface treatment agent for synthetic leather, comprising the following components by weight:

[0118] 110 parts of water-based polyurethane;

[0119] 0.6 part of polydimethylsiloxane;

[0120] 0.6 parts of defoamer, water-based defoamer, model DF-572, purchased from Dongguan Defeng Defoamer Co., Ltd.;

[0121] 1.5 parts of thickener is carboxymethyl cellulose;

[0122] 2 parts of organosilicon hand feeling agent, model HF-647, purchased from Guangzhou McGee Polymer Material Co., Ltd.;

[0123] 5 parts of matting agent, kaolin with a particle size of 0.45 μm;

[0124] 5 parts of anti-ultraviolet particles;

[0125] Plant powder 3 parts.

[0126] A kind of preparation method of water-based surface treatment agent for synthetic leather, such as figure 1 As shown, including the following process:

[0127] The preparation of S1 plant powder, the preparation process of plant powder is as follows:

[0128] 1. Pick fresh kaeba and aloe vera, wash the kaeba ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com