Compound fresh-keeping agent for pickled mustard tubers as well as preparation method and application method thereof

A composite preservation and mustard technology, applied in the preparation of preservatives, in the field of preservatives for mustard packaging, to reduce concerns about negative health effects, improve fluidity, and reduce the risk of dust explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

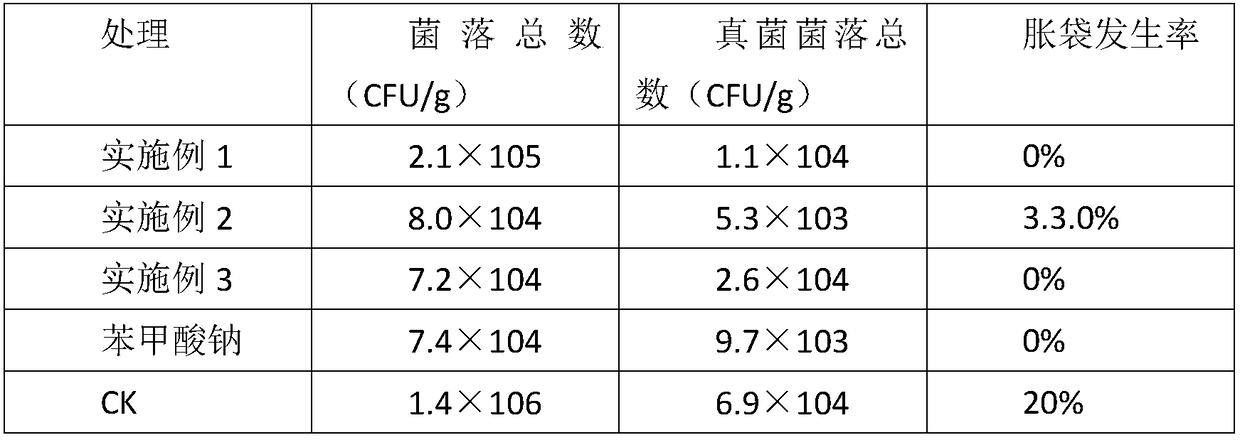

Examples

Embodiment 1

[0035] (1) Put the subordinate materials in the form of powder into a stirring powder mixer: 100kg of LAE, 50kg of potassium sorbate, 50kg of nisin, and mix for 30 minutes.

[0036] (2) 100kg of materials in step (1) and 7kg of microcrystalline cellulose were mixed in a swing mixer for 30 minutes.

[0037] (3) Dry granulate the material in step (2) in a roller press granulator, set the pressure of the roller to 5 MPa, the rotating speed of the roller to 20 rpm, and the particle size to 7 mm.

[0038] (4) Peel the marinated pickled mustard, cut into pieces, and rinse in fresh water for 10 minutes.

[0039] (5) Put 500kg of mustard greens after cutting and bleaching, 0.5kg of preservative granules in step (3), 0.2kg of citric acid, 0.2kg of erythritol, and 0.5kg of sucrose into the drum mixer, and mix for 10 minutes .

[0040] (6) On the automatic packaging line, the seasoned pickled mustard is subpackaged, vacuum-packed with opaque polyethylene / polyethylene terephthalate plas...

Embodiment 2

[0043] (1) Put the sub-materials in powder form into a stirring powder mixer: 10kg of LAE, 2kg of natamycin and 10kg of streptococin, and mix for 15 minutes.

[0044] (2) 10 kg of materials in step (1) and 1 kg of pregelatinized starch were mixed in a swing mixer for 60 minutes.

[0045] (3) Dry granulate the material in step (2) in a roller press granulator, set the pressure of the roller to 7MPa, the rotating speed of the roller to 10rpm, and the particle size to 5mm.

[0046] (4) Peel the marinated pickled mustard, cut into pieces, and rinse in fresh water for 10 minutes.

[0047] (5) 50 kg of mustard mustard after cutting and bleaching, 0.02 kg of preservative granules in step (3), 0.007 kg of acetic acid, and 0.05 kg of sucrose are put into a drum mixer, and mixed for 5 minutes.

[0048](6) On the automatic packaging line, the seasoned pickled mustard is sub-packaged, and vacuum-packed with transparent chlorinated polyethylene plastic packaging bags, and sterilized in 85...

Embodiment 3

[0051] (1) Put the sub-materials in powder form into a stirring powder mixer: 10kg of LAE, 5kg of potassium sorbate, 1kg of lysozyme, and mix for 5 minutes.

[0052] (2) 10kg of materials in step (1) and 0.7kg of microcrystalline cellulose were mixed in a swing mixer for 30 minutes.

[0053] (3) Dry granulate the material in step (2) in a roller press granulator, set the pressure of the roller to 5 MPa, the rotating speed of the roller to 20 rpm, and the particle size to 7 mm.

[0054] (4) Cut the marinated pickled mustard into strips, and rinse them in fresh water for 10 minutes.

[0055] (5) 50 kg of mustard mustard after cutting and blanching, 0.05 kg of preservative granules in step (3), 0.02 kg of citric acid, and 0.1 kg of erythritol are dropped into a drum mixer, and mixed for 10 minutes.

[0056] (6) Pack the seasoned pickled mustard in an automatic packaging line, vacuum pack it in an opaque polyethylene / polyethylene terephthalate plastic bag, and sterilize it with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com