Porous scaffold based on three-dimensional inkjet printing technology and preparation method of porous scaffold

A porous stent and inkjet printing technology, which is applied in the directions of additive manufacturing, processing and manufacturing, and manufacturing tools, can solve the problems of low 3D inkjet printing accuracy and difficulty in printing models, and achieve the effect of economical convenience and high biological safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Configure calcium phosphate bioactive ceramic printing ink;

[0037] Calcium phosphate powder, polyvinyl alcohol (PVB, Mn=70000-90000) and ethanol (Sigma) were thoroughly mixed in a ratio of 3.6:32:32 to prepare calcium phosphate-based bioactive ceramic printing ink.

[0038] (2) Configure support medium:

[0039] Mix the agar and up water at a ratio of 1:99 and heat to 90°C. After the agar is fully dissolved, lower the temperature of the agar solution to room temperature.

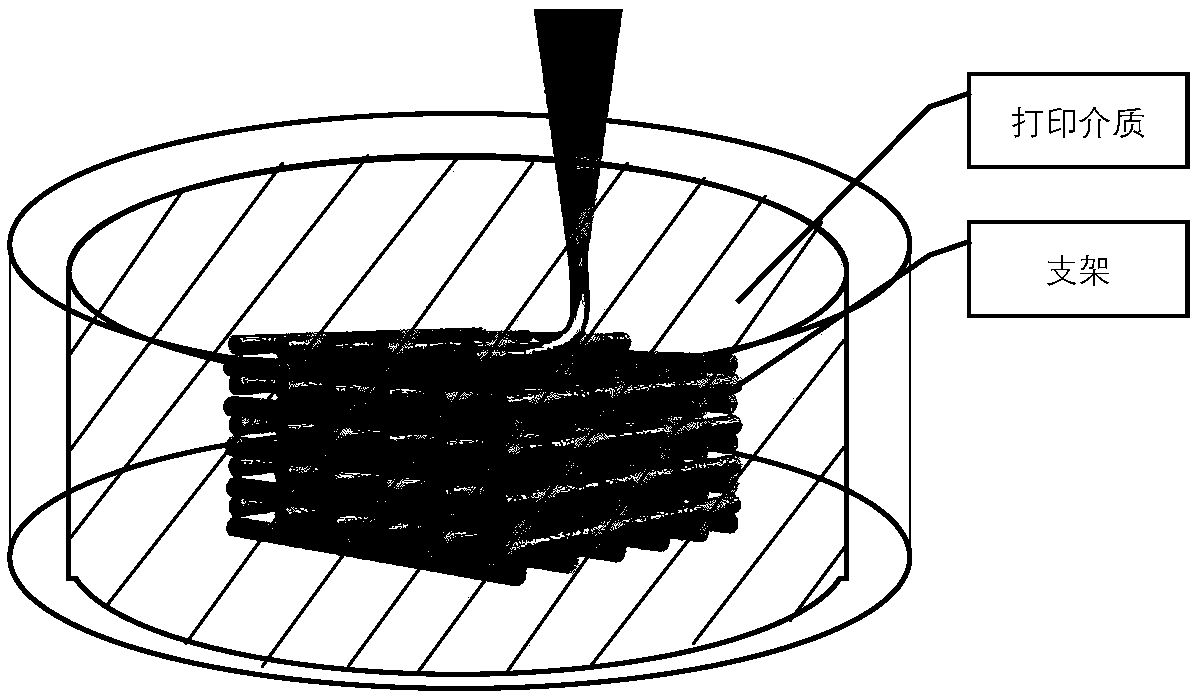

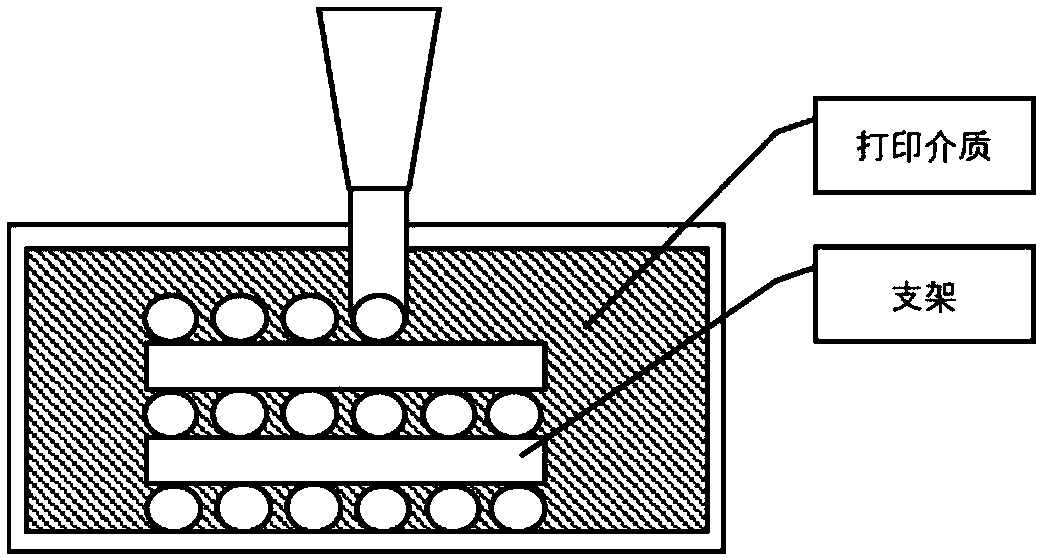

[0040] (3) Three-dimensional inkjet printing technology (3DP) was used to prepare the required scaffolds. During the printing process, the bottom of the container loaded with agar was guaranteed to be the printing platform, and the printing nozzle was always at the level of the agar liquid level.

[0041] (4) Slowly heat the agar colloid embedding the printing scaffold to 90°C, and take out the scaffold after the agar is completely melted.

[0042] The printing ink of the above-mentioned embod...

Embodiment 2

[0044] (1) Configure sodium alginate biohydrogel printing ink

[0045] Fully mix sodium alginate powder and up water at a ratio of 6:94, stir to fully dissolve sodium alginate to make printing ink.

[0046] (2) Configure support medium:

[0047] Mix agar, calcium chloride and up water in a ratio of 1:9:90 and heat to 90°C. After the agar is fully dissolved, lower the temperature of the agar solution to room temperature.

[0048] (3) Three-dimensional inkjet printing technology (3DP) was used to prepare sodium alginate scaffolds. During the printing process, the bottom of the container loaded with agar was guaranteed to be the printing platform, and the printing nozzle was always at the height of the agar liquid level.

[0049] (4) Slowly heat the agar colloid embedding the printing scaffold to 90°C, and take out the scaffold after the agar is completely melted.

[0050] In the preparation process of the above examples, the printing ink is sodium alginate solution, which is a v...

Embodiment 3

[0052] (1) Configure gelatin biohydrogel printing ink

[0053] Mix the gelatin powder and up water at a ratio of 10:90, and stir to fully dissolve the gelatin to make printing ink.

[0054] (2) Configure support medium:

[0055] Mix agar, glutaraldehyde and up water in a ratio of 1:2:97 and heat to 90°C. After the agar is fully dissolved, lower the temperature of the agar solution to room temperature.

[0056] (3) Three-dimensional inkjet printing technology (3DP) was used to prepare the gelatin scaffold. During the printing process, the bottom of the container loaded with agar was guaranteed to be the printing platform, and the printing nozzle was always at the level of the agar liquid level.

[0057] (4) Slowly heat the agar colloid embedding the printing scaffold to 90°C, and take out the scaffold after the agar is completely melted.

[0058] In this embodiment, the printing ink is a gelatin solution, which is a very common raw material for a scaffold, and a three-dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com