High-strength and high-fire-resistance oxygen-nitrogen foam glass and preparation method thereof

A technology of foam glass and oxynitride glass, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., and can solve the problems of unsuitable, uniform distribution, and low refractoriness of oxynitride glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

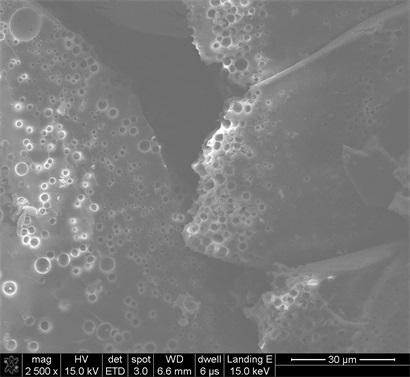

Image

Examples

Embodiment 1

[0012] Put 450 grams of basalt powder and 50 grams of silicon nitride powder into a ball mill and mill for 30 minutes. After mixing, pour the powder into a boron nitride crucible, put it into an atmosphere furnace protected by nitrogen, and melt it at 1700 ° C. 4 hours. The melted glass liquid is poured on the stainless steel sheet under the protection of nitrogen to obtain broken oxynitride glass, and then the oxynitride glass powder is obtained after ball milling. Put the oxynitride glass powder into a corundum mold coated with boron nitride, put it into an air atmosphere resistance furnace at 1200°C and keep it warm for 60 minutes to obtain light-weight, high-strength, high-refractoriness oxynitride foam glass. The nitrogen content in the oxygen-nitrogen foam glass is 3.99wt%, the density is 1.8g / cm3, the compressive strength is 10MPa, and the refractory temperature is 920°C.

Embodiment 2

[0014] Put 350 grams of basalt powder and 150 grams of aluminum nitride powder into a ball mill and mill for 30 minutes. After mixing, pour the powder into a boron nitride crucible, put it into an atmosphere furnace protected by nitrogen, and melt it at 1650 ° C. 4 hours. The melted glass liquid is poured on the stainless steel sheet under the protection of nitrogen to obtain broken oxynitride glass, and then the oxynitride glass powder is obtained after ball milling. Put the oxynitride glass powder into a stainless steel tool coated with boron nitride, and put it into an air atmosphere resistance furnace at 1100°C for 20 minutes to obtain a lightweight, high-strength, high-refractoriness oxynitride foam glass. The nitrogen content in the oxygen-nitrogen foam glass is 10.19wt%, the density is 1.6g / cm3, the compressive strength is 30MPa, and the refractory temperature is 1040℃.

Embodiment 3

[0016] Put 400 grams of basalt powder and 100 grams of boron nitride powder into a ball mill and mill for 30 minutes. After mixing, pour the powder into a boron nitride crucible, put it into an atmosphere furnace protected by ammonia gas, and heat it at 1560°C Melt for 4 hours. The melted glass liquid is poured on the stainless steel sheet under the protection of nitrogen to obtain broken oxynitride glass, and then the oxynitride glass powder is obtained after ball milling. Put the oxynitride glass powder into a corundum mold coated with boron nitride, put it into an air atmosphere resistance furnace at 1150°C for 40 minutes, and obtain light, high-strength, high-refractority oxynitride foam glass. The nitrogen content in the oxygen-nitrogen foam glass is 12.13wt%, the density is 0.9g / cm3, the compressive strength is 6MPa, and the refractory temperature is 1000℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com