High-moisture content soft soil consolidating agent and application thereof

A technology of high moisture content and curing agent, which is applied in the field of soft soil curing agent and high moisture content soft soil curing agent, which can solve the problems of failure to fill pores, decrease in compression performance, and cracking of soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5

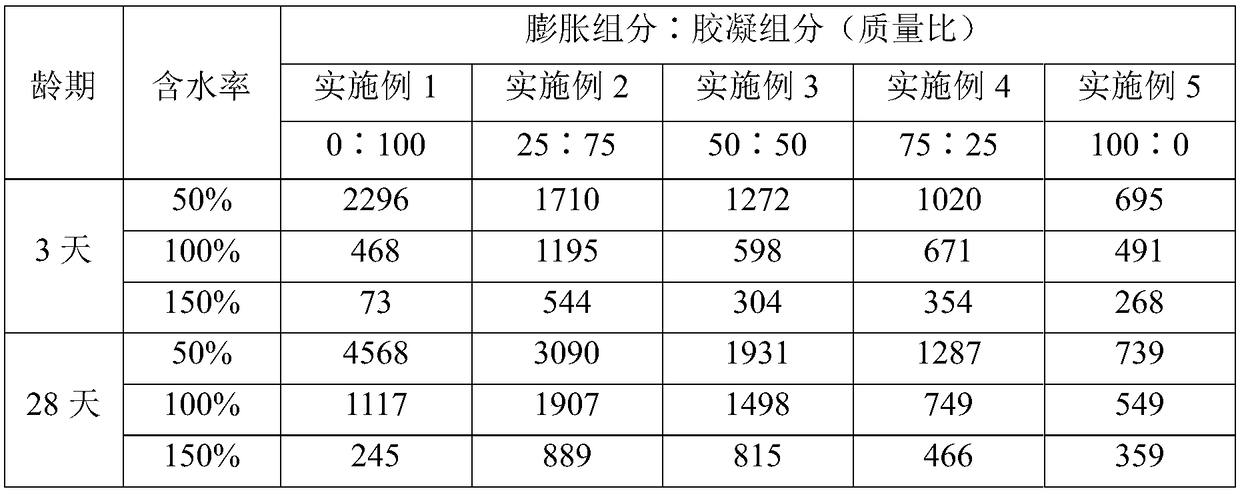

[0057] A high water content soft soil curing agent, comprising an expansive component and a gelling component, the expansive component includes sulphoaluminate cement clinker, gypsum and lime, and the gelling component is ordinary silicate Cement; wherein, the mass ratio of the expansion component to the gelling component is 0:100, 25:75, 50:50, 75:25 and 100:0, and the sulphoaluminate cement clinker and gypsum in the expansion component , The mass ratio of lime is 50:40:10.

[0058] When the curing agent prepared according to the above ratio is 16% in the amount of curing agent, 50%, 100% and 150% in water content, and 3 days and 28 days in the curing period, the average unrestricted average value of the solidified soil test blocks in each group The compressive strength values are detailed in Table 1 below.

[0059] Table 1 The strength value (kPa) of solidified soil with different water content and different proportions

[0060]

[0061]It can be seen from Table 1 tha...

Embodiment 6

[0063] A high water content soft soil curing agent, comprising an expansive component and a gelling component, the expansive component includes sulphoaluminate cement clinker, gypsum and lime, and the gelling component is ordinary silicate Cement; wherein, the mass ratio of the expansion component to the gelling component is 25:75, and the mass ratio of the sulphoaluminate cement clinker, gypsum and lime in the expansion component is 40:48:12.

[0064] The curing agent prepared according to the above ratio, when the curing agent dosage is 8% and the water content is 100%, the average unconfined compressive strength of the solidified soil test block for 3 days is 254kPa, and the average unconfined compressive strength for 28 days is 254kPa. The compressive strength is 485kPa.

Embodiment 7

[0066] A high water content soft soil curing agent, comprising an expansive component and a gelling component, the expansive component includes sulphoaluminate cement clinker, gypsum and lime, and the gelling component is ordinary silicate Cement; wherein, the mass ratio of the expansion component to the gelling component is 25:75, and the mass ratio of the sulphoaluminate cement clinker, gypsum and lime in the expansion component is 60:32:8.

[0067] With the curing agent prepared according to the above ratio, when the curing agent dosage is 25% and the water content is 100%, the average unconfined compressive strength of the solidified soil test block for 3 days is 2648kPa, and the average unconfined compressive strength for 28 days is 2648kPa. The compressive strength is 4216kPa.

[0068] According to the function of each component in the embodiment, other similar components or industrial waste residues can be used instead, but its activity must be improved through physical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com