Ester super sustained release polycarboxylic acid slump retaining agent and preparation method thereof

An ultra-sustained-release, polycarboxylic acid technology, applied in the field of building materials, can solve the problems of inability to fully meet market demand, cost increase, insufficient slump retention performance, etc., and achieve fast speed, slump retention, and slump retention capability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

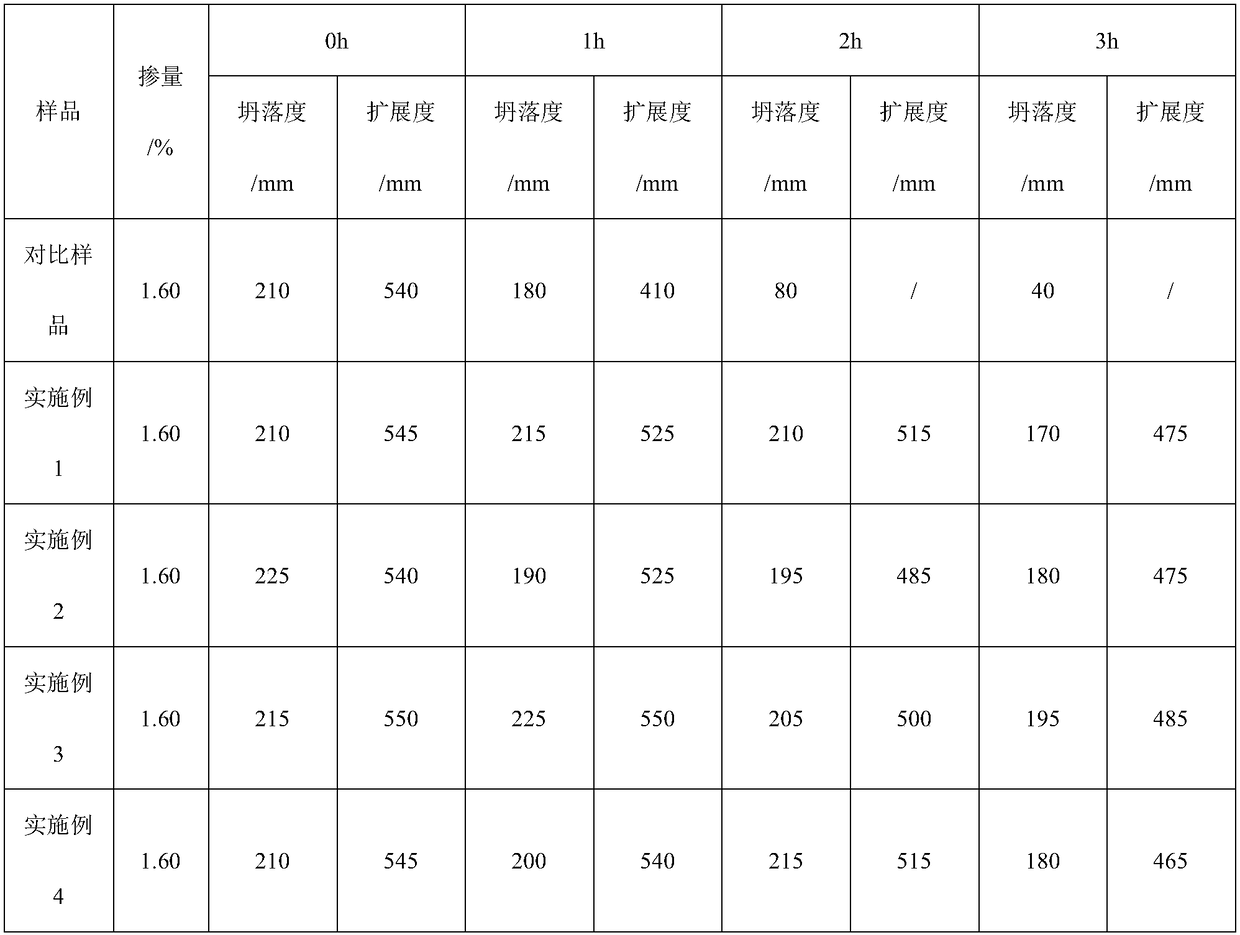

Embodiment 1

[0029] (1) Preparation of unsaturated esterified small monomers:

[0030] Under normal pressure, 41 parts of methacrylic acid, 71 parts of propionic acid, 130 parts of 3-bis(2-hydroxyethyl)amino-2-hydroxypropanesulfonic acid (DIPSO) were added to the reactor, and 0.25 Parts of titanium trichloride, 0.13 parts of 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl radical and 13 parts of petroleum ether are used for esterification reaction, and the temperature of the esterification reaction is 100°C , the reaction time is 3 hours, and after the reaction is completed, it is lowered to room temperature, and the unsaturated esterified small monomer is obtained.

[0031] (2) Esterification reaction: in parts by weight, 100.00 parts of polyethylene glycol monomethyl ether with a weight average molecular weight of 400, 129 parts of methacrylic acid, 11.45 parts of concentrated sulfuric acid and 4.58 parts of β-phenylnaphthylamine were placed in In the first reaction device, the temperatu...

Embodiment 2

[0035] (1) Preparation of unsaturated esterified small monomers:

[0036] Under normal pressure, 60 parts of methacrylic acid, 162 parts of butyric acid, 130 parts of 3-bis(2-hydroxyethyl)amino-2-hydroxypropanesulfonic acid (DIPSO) were added to the reactor, and 0.55 1 part of sodium p-toluenesulfonate, 0.45 part of N-nitroso-N-phenylhydroxylamine aluminum and 18 parts of cyclohexane, carry out esterification reaction, the esterification reaction temperature is 110 ℃, the reaction time is 4 hours, and the reaction ends After cooling down to room temperature, the unsaturated esterified small monomer is obtained.

[0037](2) Esterification reaction: in parts by weight, 100.00 parts of polyethylene glycol monomethyl ether with a weight average molecular weight of 1000, 43 parts of methacrylic acid, 2.15 parts of concentrated sulfuric acid and 0.72 parts of β-phenylnaphthylamine were placed in In the first reaction device, the temperature was kept at 120° C. for 4 hours to obtain...

Embodiment 3

[0041] (1) Preparation of unsaturated esterified small monomers:

[0042] Under normal pressure, 90 parts of methacrylic acid, 85 parts of butyric acid, 130 parts of 3-bis(2-hydroxyethyl)amino-2-hydroxypropanesulfonic acid (DIPSO) were added to the reactor, and 0.6 Parts of titanium trichloride, 0.35 parts of 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxygen free radicals and 40 parts of petroleum ether are subjected to esterification reaction at a temperature of 120°C , the reaction time is 5 hours, after the reaction is completed, it is lowered to room temperature, and the unsaturated esterified small monomer is obtained.

[0043] (2) Esterification reaction: by weight, 100.00 parts of molecular weight is 3000 polyethylene glycol monomethyl ether, 11.48 parts of methacrylic acid, 2.23 parts of concentrated sulfuric acid and 1.11 parts of β-phenylnaphthylamine are placed in the first In the reaction device, the temperature was kept at 110° C. for 5 hours to obtain the esterif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com