High-performance PET (Polyethylene Terephthalate) composite material capable of being applied to medium and low mold temperature rapid crystallization molding and preparation method of PET composite material

A composite material, high-performance technology, applied in the polymer field, can solve the problems of low heat resistance, long injection molding cycle, incomplete crystallinity, etc., achieve excellent toughness and heat resistance, shorten the injection molding cycle, and excellent mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

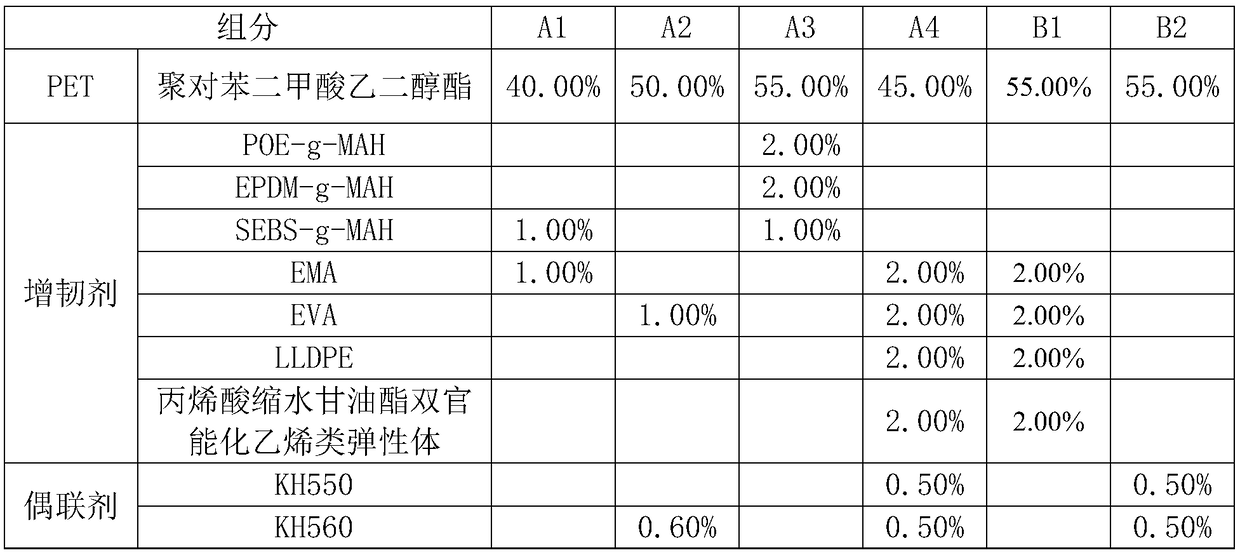

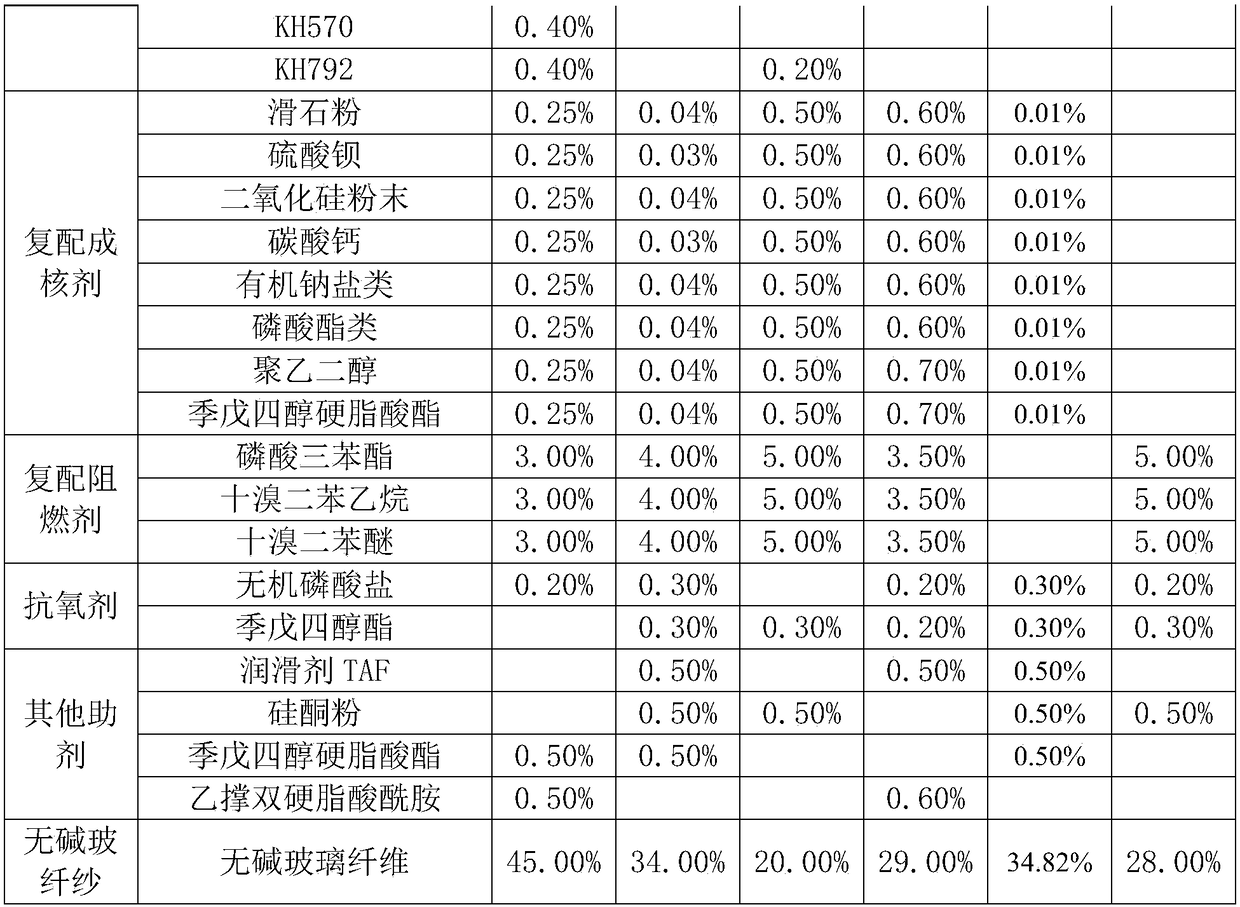

[0029] (1) Put PET with a viscosity of 0.78dL / g in a blower dryer at 110°C for 3 hours, and set aside;

[0030] (2) According to the weight percentage of Table 1, the talcum powder, barium sulfate, silicon dioxide powder, calcium carbonate, organic sodium salts, phosphoric acid esters, polyethylene glycol, pentaerythritol stearate, inorganic phosphoric acid Salt, pentaerythritol stearate, and ethylene bisstearic acid amide are mixed uniformly to obtain a composition material, for subsequent use;

[0031] (3) According to the weight percentage in Table 1, take PET, alkali-free glass fiber yarn, SEBS-g-MAH, EMA, KH570, KH792 and put into the mixer and mix evenly, then add the composition material and mix evenly again, finally add triphosphate The compound flame retardant of phenyl ester, decabromodiphenyl ether and decabromodiphenylethane is mixed evenly;

[0032] (4) Add the mixed materials into the twin-screw extruder to granulate. The temperature of each section of the twin-...

Embodiment 2

[0035] (1) Put PET with a viscosity of 0.78dL / g in a blower dryer at 110°C for 3.5 hours, and set aside;

[0036] (2) According to the weight percentage of Table 1, the talcum powder, barium sulfate, silicon dioxide powder, calcium carbonate, organic sodium salts, phosphoric acid esters, polyethylene glycol, pentaerythritol stearate, inorganic phosphoric acid Salt, pentaerythritol ester, pentaerythritol stearate, silicone powder, and lubricant TAF are mixed uniformly to obtain a composition material, which is set aside;

[0037] (3) According to the weight percentage in Table 1, weigh PET, alkali-free glass fiber yarn, EVA, and KH560 and put them into the mixer and mix them evenly, then add the composition material and mix evenly again, finally add triphenyl phosphate, decabromodiphenyl ether Mix evenly with the compound flame retardant of decabromodiphenylethane;

[0038] (4) Add the mixed materials into the twin-screw extruder to granulate. The temperature of each section o...

Embodiment 3

[0041] (1) Dry the PET with a viscosity of 0.78dL / g in a blast dryer at 110°C for 3.5H, and set aside;

[0042] (2) By weight percentage in Table 1, the weighed talcum powder, barium sulfate, silicon dioxide powder, calcium carbonate, organic sodium salts, phosphoric acid esters, polyethylene glycol, pentaerythritol stearate, pentaerythritol ester , silicone powder mixed evenly to obtain a composite material, set aside;

[0043] (3) According to the weight percentage in Table 1, weigh PET, E-glass fiber yarn, POE-g-MAH, EPDM-g-MAH, SEBS-g-MAH, KH792 and put them into the mixer to mix evenly, then add the composition Mix evenly again, and finally add triphenyl phosphate, decabromodiphenyl ether and decabromodiphenylethane compound flame retardant and mix evenly;

[0044] (4) Add the mixed materials into the twin-screw extruder to granulate. The temperature of each section of the twin-screw extruder is: 230°C in zone 1, 234°C in zone 2, 235°C in zone 3, and 235°C in zone 4. 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com