Titanium alloy protecting coating and preparation method thereof

A technology of protective coating and titanium alloy, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problems of passivation film damage, limited titanium alloy application, weak coating bearing capacity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

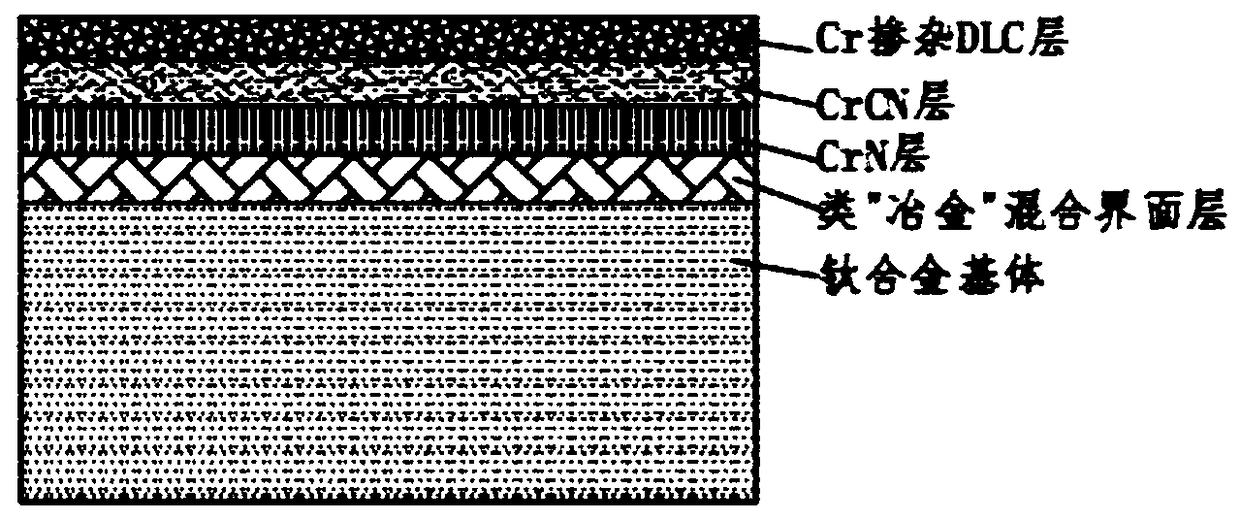

[0029] The present invention also provides a method for preparing the titanium alloy protective coating described in the above technical solution, comprising the following steps:

[0030] (1) Nitrogen ion implantation is performed on the surface of the titanium alloy substrate to obtain a metallurgical mixed interface layer;

[0031] (2) On the surface of the metallurgical mixed interface layer, a CrN layer, a CrCN layer and a Cr-doped DLC layer are sequentially deposited by a plasma-enhanced physical vapor deposition method.

[0032] In the present invention, the titanium alloy substrate is preferably pretreated.

[0033] In the present invention, the pretreatment preferably includes cleaning and drying; the method of the cleaning and drying is not particularly limited in the present invention, as long as a clean and dry titanium alloy substrate can be obtained.

[0034] In the embodiment of the present invention, the cleaning is preferably ultrasonic cleaning; the ultrasoni...

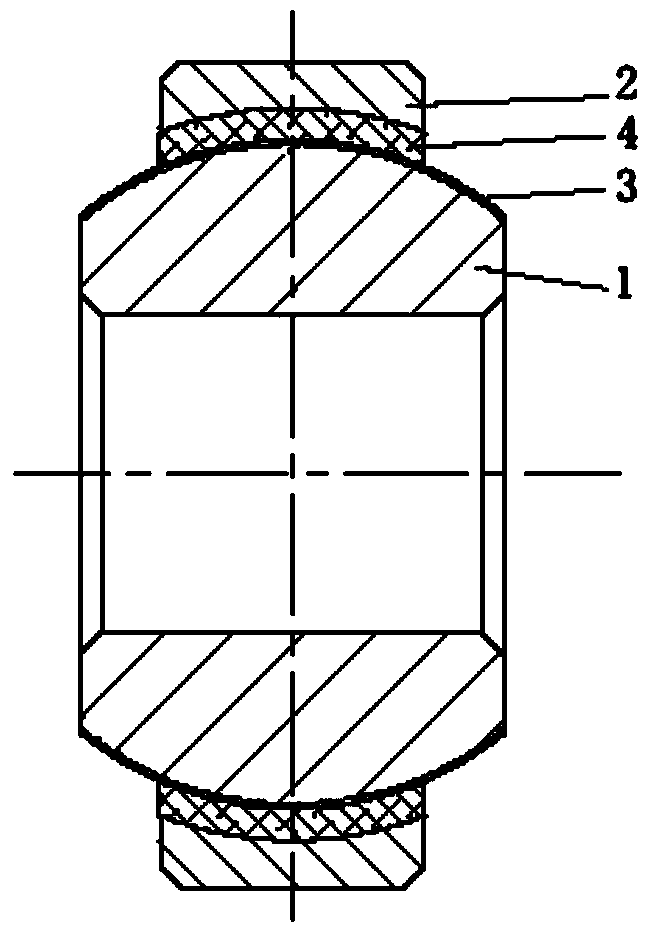

Embodiment 1

[0047] 1. Clean the inner ring of the titanium alloy joint bearing with an industrial-specific seven-slot ultrasonic wave for 15 minutes. After cleaning, blow it dry and keep it dry in a vacuum oven for 15 minutes;

[0048] 2. Install the cleaned inner ring of the joint bearing on the fixture rod, put it on the rotating frame of the vacuum chamber, and then when the vacuum degree of the vacuum chamber reaches 5×10 -3 After Pa, turn on the radio frequency power supply for nitrogen ion implantation. The nitrogen ion implantation process is as follows: the flow rate of nitrogen gas gradually increases from 120 sccm to 150 sccm, the pressure of nitrogen gas gradually increases from 0.6 Pa to 0.8 Pa, the radio frequency power is 0.5 kW, and the injection voltage 20kV, injection frequency 100Hz, injection pulse width 20μs, injection time 8h; after the injection is completed, a metallurgical mixed interface layer is obtained;

[0049] 3. Clean the surface of the metallurgical mixed i...

Embodiment 2

[0056] 1. Process the titanium alloy key bearing inner ring according to the method described in step 1 of embodiment 1;

[0057] 2. Install the cleaned inner ring of the joint bearing on the fixture rod, put it on the rotating frame of the vacuum chamber, and then when the vacuum degree of the vacuum chamber reaches 5×10 -3 After Pa, turn on the radio frequency power supply for nitrogen ion implantation. The nitrogen ion implantation process is as follows: the flow rate of nitrogen gas is gradually increased from 80 sccm to 120 sccm, the pressure of nitrogen gas is gradually increased from 0.4Pa to 0.6Pa, the radio frequency power is 1kW, and the injection voltage is 40kV , the injection frequency is 100Hz, the injection pulse width is 20μs, and the injection time is 4h; after the injection is completed, a metallurgical mixed interface layer is obtained;

[0058] 3. according to the method described in embodiment 1 step 3, carry out glow plasma to the metallurgical mixed inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com