Air flow drying system used for vinasse protein fodder production

A technology of distiller's grains protein feed and airflow drying, which is used in biomass drying, drying solid materials, drying cargo processing and other directions, can solve the problems of short service life, frequent maintenance, wear and tear of heat exchange tubes, etc., and achieves low manufacturing cost and energy. Low consumption, easy to produce effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

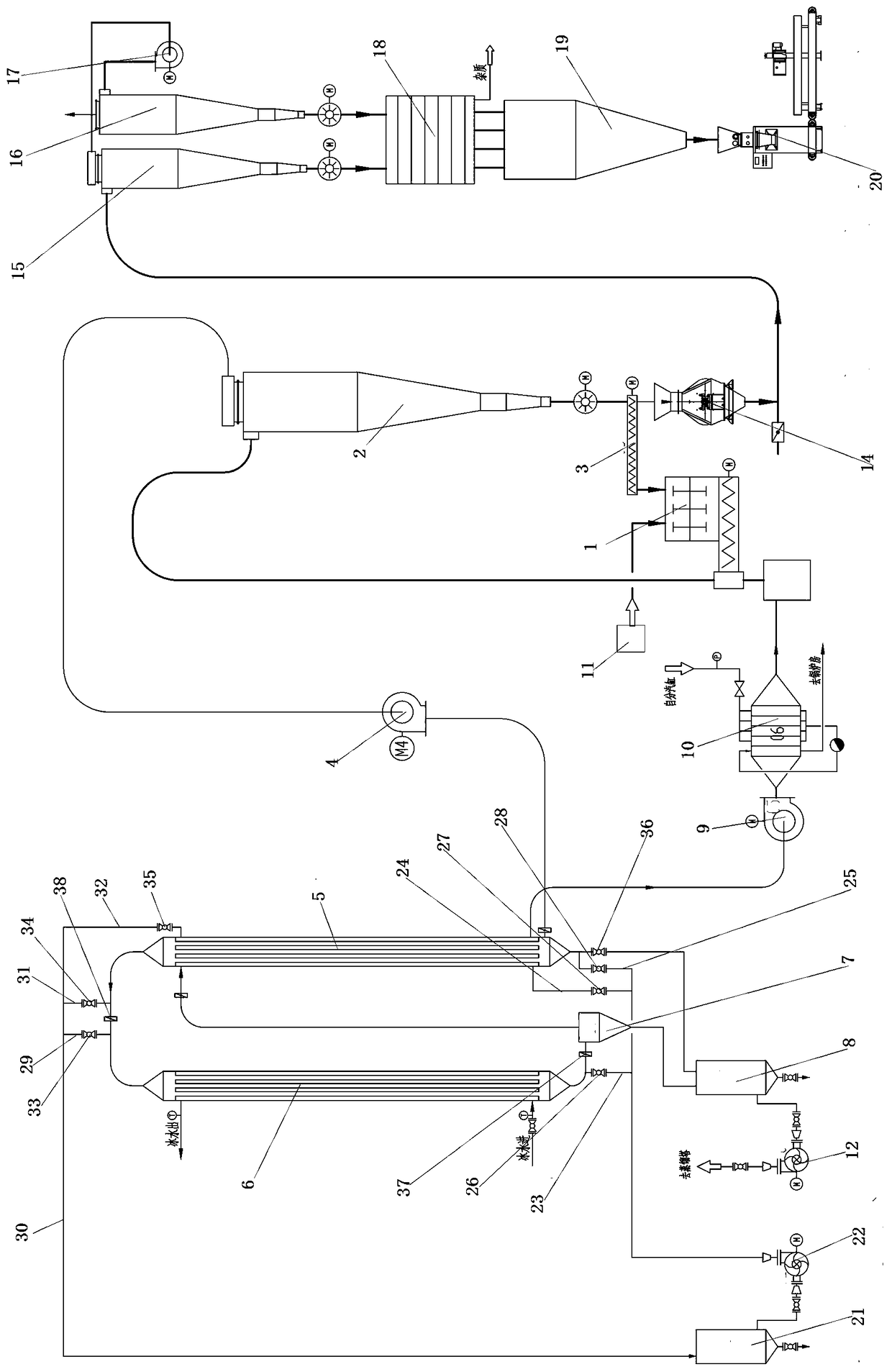

[0020] Such as figure 1 Shown, a kind of airflow drying system for distiller's grain protein feed production, comprises feeder 1, drying unloader 2, circulation conveyer 3, induced draft fan 4, cold air heat exchanger 5, ice water heat exchanger 6, air Liquid separator 7, condensation recovery tank 8, blower 9, heater 10 and crushing packaging system, the feed port of the feeder 1 is connected to the wet material source 11, and the discharge port of the feeder 1 is connected to The feed port of the dry unloader 2, the discharge port of the dry unloader 2 is connected to the feed port of the circulation conveyor 3, the dry unloader 2 is a cyclone unloader, the discharge port is provided with an air lock, The discharge port of the circulation conveyor 3 is connected to the feed port of the feeder 1, and the discharge port of the circulation conveyor 3 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com