Composite coating containing deodorizing module and preparation method thereof

A composite coating, coating liquid technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problem of inability to remove aldehydes and mercaptans pollutants, unstable initial deodorization performance, and long-lasting deodorization. Poor performance and other problems, achieve good long-term deodorization effect, solve the effect of large influence of preparation method and difficult activity attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

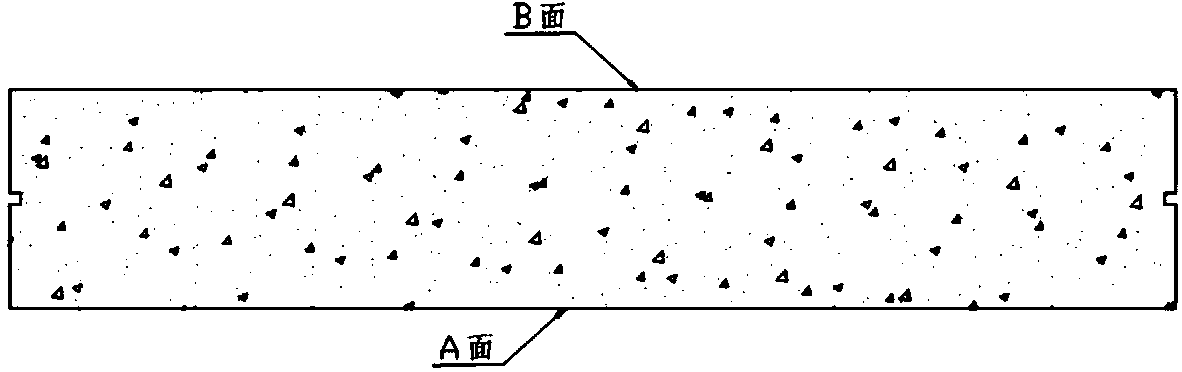

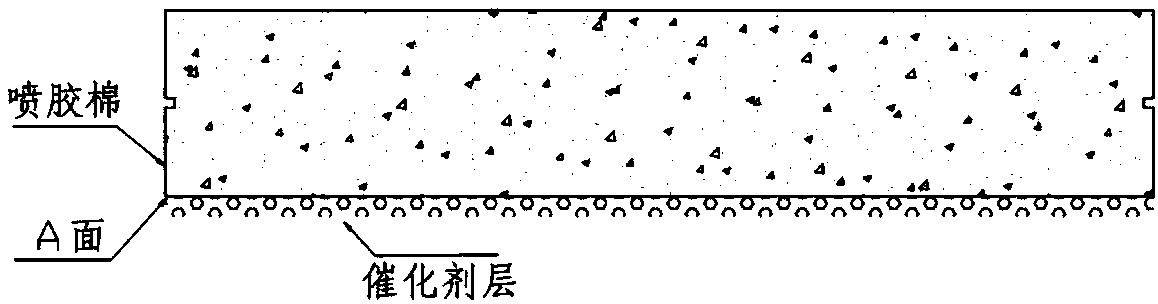

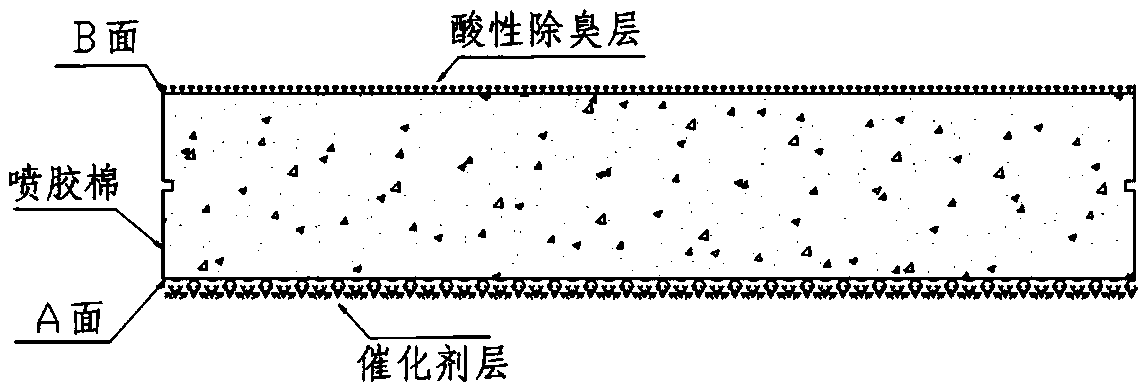

[0038] A deodorizing module containing a composite coating, using glued cotton as a carrier, a catalyst layer is attached to one side of the glued cotton, and an acidic deodorizing layer is attached to the opposite side.

[0039] The preparation method of the deodorizing module containing composite coating described in this embodiment comprises the following steps:

[0040] (1) Prepare coating solution A and coating solution B in proportion;

[0041] The coating solution A includes the following components in mass percentage: MnO 2 Powder 10%, Acrylic Glue 20%, Cellulose 10% and Water 60%;

[0042] The coating liquid B includes the following components in mass percentage: 5% citric acid, 10% activated carbon, 20% acrylic glue and 65% water;

[0043] (2) Coating solution A is sprayed onto the A face of spray-bonded cotton, is dried to form catalyst layer, obtains such as figure 2 The intermediate product coated with the catalyst coating is shown; the coating solution B is s...

Embodiment 2

[0045] A deodorizing module containing a composite coating, using glued cotton as a carrier, a catalyst layer and an acidic deodorizing layer attached to one side of the sprayed glued cotton, and an acidic deodorizing layer attached to the opposite side.

[0046] The preparation method of the deodorizing module containing composite coating described in this embodiment comprises the following steps:

[0047] (1) Prepare coating solution A and coating solution B in proportion;

[0048] The coating solution A includes the following components in mass percentage: MnO 2 Powder 10%, Acrylic Glue 20%, Cellulose 10% and Water 60%;

[0049] The coating liquid B includes the following components in mass percentage: 5% citric acid, 10% activated carbon, 20% acrylic glue and 65% water;

[0050] (2) Spray the coating solution A onto the A side of the glued cotton, and dry to form a catalyst layer; spray the coating solution B onto the A side and the B side opposite to the A side, and dry...

Embodiment 3

[0052] A deodorizing module containing a composite coating, using glued cotton as a carrier, a catalyst layer attached to one side of the glued cotton, and a catalyst layer and an acidic deodorizing layer attached to the opposite side.

[0053] The preparation method of the deodorizing module containing composite coating described in this embodiment comprises the following steps:

[0054] (1) Prepare coating solution A and coating solution B in proportion;

[0055] The coating solution A includes the following components in mass percentage: MnO 2 Powder 10%, Acrylic Glue 20%, Cellulose 10% and Water 60%;

[0056] The coating liquid B includes the following components in mass percentage: 5% citric acid, 10% activated carbon, 20% acrylic glue and 65% water;

[0057] (2) Spray the coating solution A onto the A side of the glued cotton and the B side opposite to the A side, and dry to form a catalyst layer; spray the coating solution B onto the B side, and dry to form an acidic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com