Method for preparing gradient ceramics by electric field-assisted high-valence counter ion controlled release curing

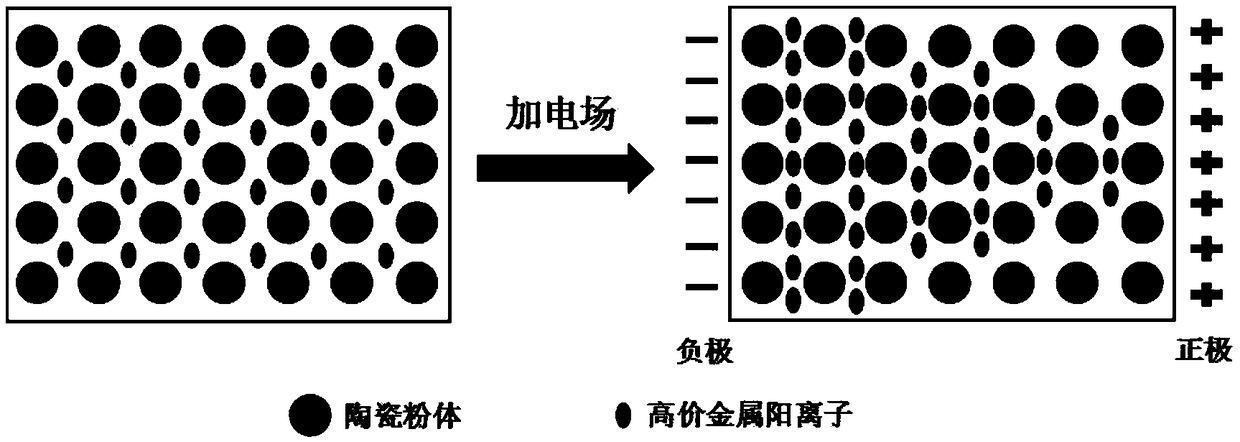

An electric field-assisted and counter-ion technology, which is applied in the field of electric-field-assisted high-priced counter-ion controlled-release solidification to prepare gradient ceramics, achieves the effects of improving molding efficiency, continuous composition, and avoiding uneven transition of composition gradients and thermodynamic mismatch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 6.5g / L calcium iodate, 2.0wt% glyceryl diacetate cured 3.0wt% tetramethylammonium hydroxide dispersed 65vol% SiO at 20V / m electric field strength 2 slurry.

[0042] Mix 100g of silica powder, 3.0g of tetramethylammonium hydroxide and 24.5g of water, and ball mill for 1 hour at a rate of 300r / min to prepare a negatively charged ceramic slurry with a solid phase volume fraction of 65%. Then add 0.54g of calcium iodate, mix and mill at a ball milling rate of 250r / min for 20min, stir and degas under vacuum for 15min, then add 2.0g of glyceryl diacetate, stir the glass rod for 30s, inject into the mold, put into the field In an electrostatic field of 20V / m, heat the silica gel heating pad to 60°C and keep it for 1 hour, then demould it, dry it at 70°C for 24 hours, then raise the temperature to 1200°C at a rate of 5°C / min and hold it for 3 hours to obtain gradient silica ceramic sintered body.

Embodiment 2

[0044] 3.0wt% magnesium citrate, 1.0wt% ethyl acetate solidified 1.0wt% ammonium citrate dispersed 50vol% Al2O3 slurry at 5V / m electric field strength.

[0045] Mix 100g of alumina powder, 1.0g of ammonium citrate and 25.2g of water, and ball mill at a rate of 250r / min for 1.5h to prepare a negatively charged ceramic slurry with a solid phase volume fraction of 50%, and then add 3.0 g magnesium citrate, mix and ball mill for 30min at a ball milling rate of 200r / min, stir and degas under vacuum for 18min, then add 1.0g of ethyl acetate, stir the glass rod for 50s and then inject into the mold, put in a field strength of 5V / m In the electrostatic field, the silica gel heating pad was heated to 80°C for 0.5h and demolded, dried at 80°C for 12h, and then heated to 1500°C at a heating rate of 8°C / min for 2h to obtain a gradient alumina ceramic sintered body.

Embodiment 3

[0047] 2.5wt% magnesium oxide, 3.0wt% glycerol triacetate cured 5.0wt% ammonium polyacrylate dispersed 45vol% Si3N4 slurry under the electric field strength of 50V / m.

[0048] Mix 100g of silicon nitride powder, 5.0g of ammonium polyacrylate and 38.2g of water, and ball mill for 2.0h at a rate of 200r / min to prepare a negatively charged ceramic slurry with a solid phase volume fraction of 45%, and then add 2.5g of magnesia, mixed and milled at a ball milling rate of 250r / min for 15min, stirred and degassed under vacuum for 20min, then added 3.0g of glycerol triacetate, stirred for 40s with a glass rod, and then injected into the mold, and the field strength was 50V / In an electrostatic field of m, heat the silica gel heating pad to 45°C and keep it for 2.0 hours, then demould it, dry it at 75°C for 18 hours, then raise the temperature to 2000°C at a heating rate of 5°C / min and hold it for 4 hours to obtain a sintered gradient silicon nitride ceramic body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com