A kind of method of rectification purification methoxyacetone

A technology of pure methoxyacetone and methoxyacetone, which is applied in the field of rectification and purification of methoxyacetone, can solve the problems of low reaction efficiency and equipment utilization, large one-time investment, and low rectification efficiency, etc., to improve equipment Effects of utilization rate and production efficiency, small initial investment, and high distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

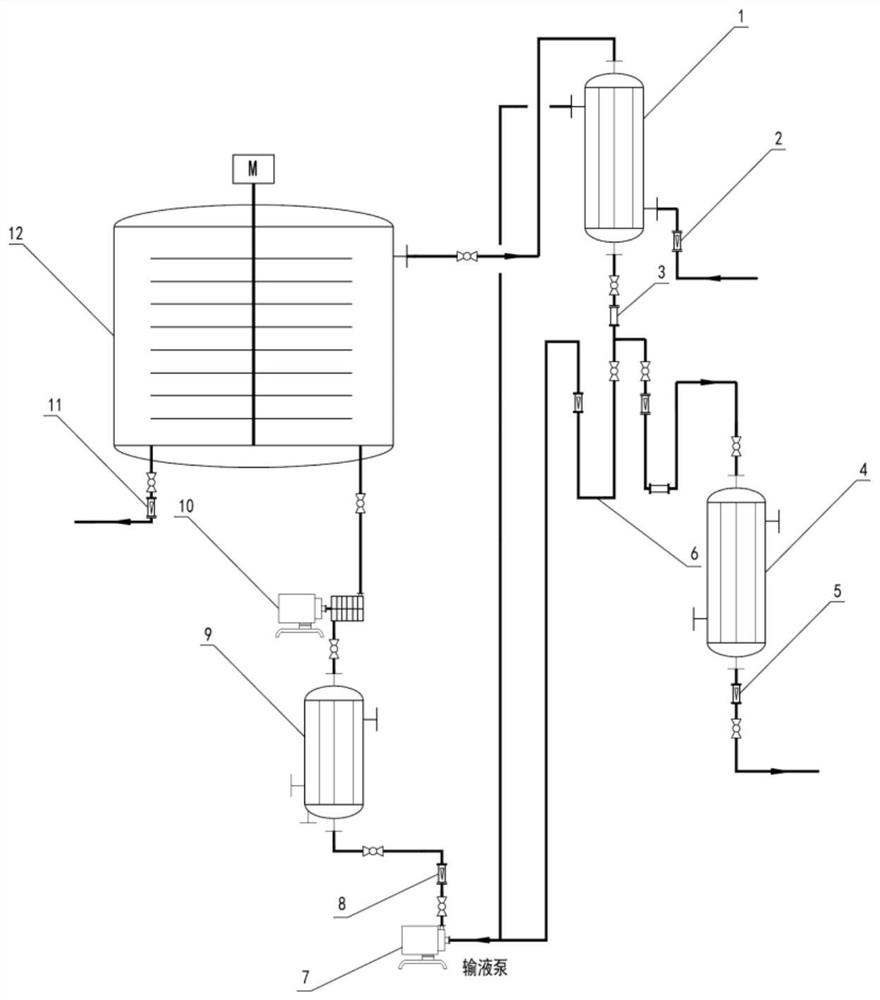

Embodiment 1

[0017] The mixed solution of methoxyacetone-propylene glycol methyl ether with a mass percentage of methoxyacetone of 20% is preheated to 90°C through a spiral wound tube heat exchanger at a temperature of 40°C, and then passed through an infusion pump, flow rate After being heated to 120°C by the preheater, it continues to enter the atomizer, and the atomized vapor-liquid mixture enters the high-gravity rectification device, and the reflux ratio of the rectification equipment in the high-gravity rectification device is controlled to 6. The pressure is 0.4MPa, the content of methoxyacetone in the product is 95.5%, and it is extracted through the condenser to reach a qualified product; the recovery of propylene glycol methyl ether is applied mechanically.

Embodiment 2

[0019] The mixed solution of methoxyacetone-propylene glycol methyl ether with a mass percentage of methoxyacetone of 60% is preheated to 100°C through a spiral wound tube heat exchanger at a temperature of 60°C, and then passed through an infusion pump, flow rate After being heated to 130°C by the preheater, it continues to enter the atomizer, and the atomized vapor-liquid mixture enters the high-gravity rectification device, and the reflux ratio of the rectification equipment of the high-gravity rectification device is controlled to 3. The internal pressure is 0.2MPa, and the content of methoxyacetone in the product is 96%, which is extracted by the condenser to reach a qualified product; propylene glycol methyl ether is recovered and used mechanically.

Embodiment 3

[0021] The mixed solution of methoxyacetone-propylene glycol methyl ether with a mass percentage of methoxyacetone of 40% is preheated to 95°C through a spiral wound tube heat exchanger at a temperature of 50°C, and then passed through an infusion pump, flow rate After being heated to 120°C by the preheater, it continues to enter the atomizer, and the atomized vapor-liquid mixture enters the high-gravity rectification device, and the high-gravity rectification device is controlled to control the reflux ratio to 1, and the pressure 0.3MPa, the content of methoxyacetone in the product is 98%, and it is extracted through the condenser to reach a qualified product; propylene glycol methyl ether is recovered and used mechanically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com