Tubular reactor of 3-hydroxytetrahydrofuran

A hydroxytetrahydrofuran, tubular reactor technology, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve the problems of accelerating reaction speed, safety risks, consumption Sodium borohydride and other problems, to avoid safety risks, safe and controllable speed, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

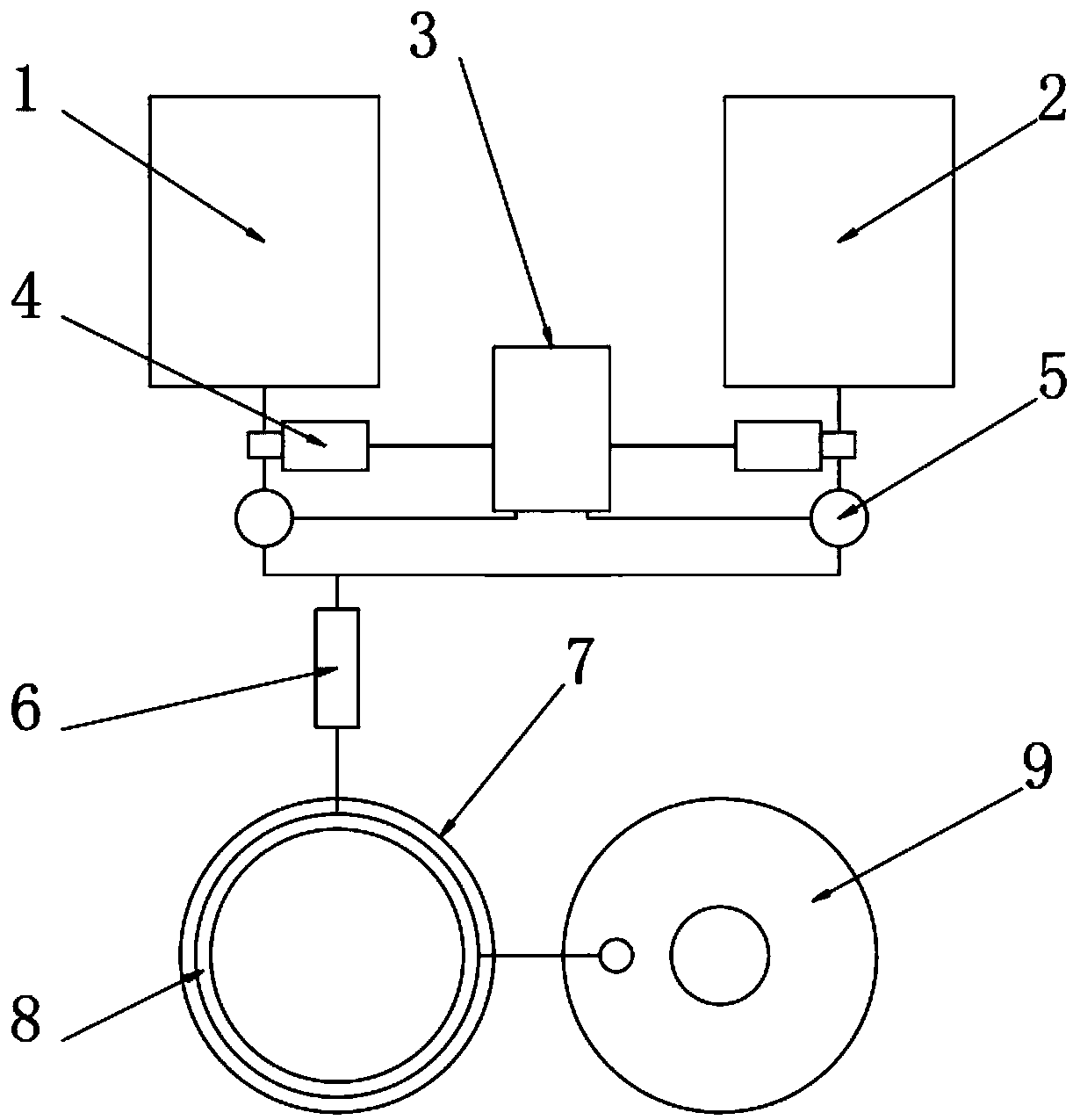

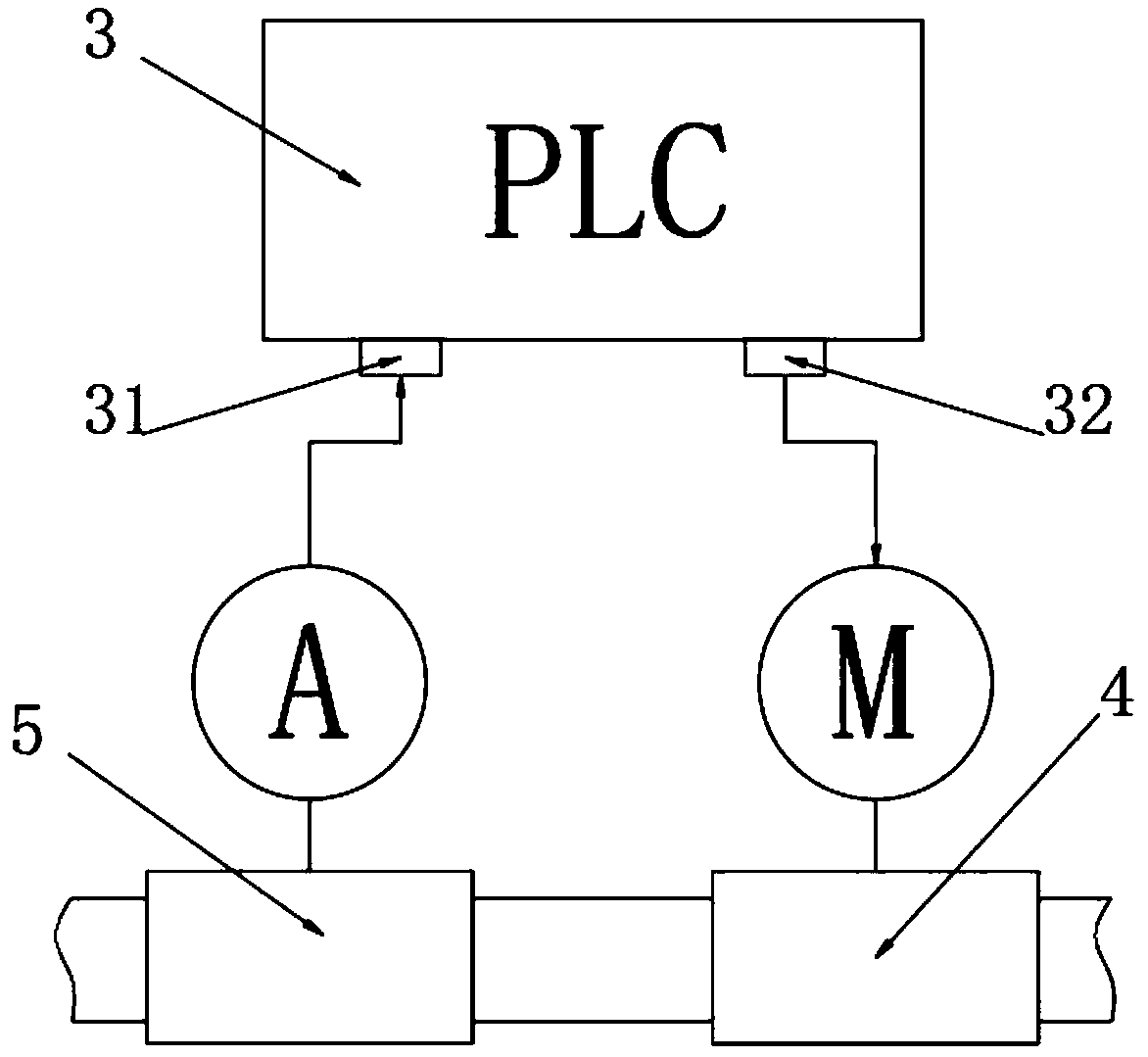

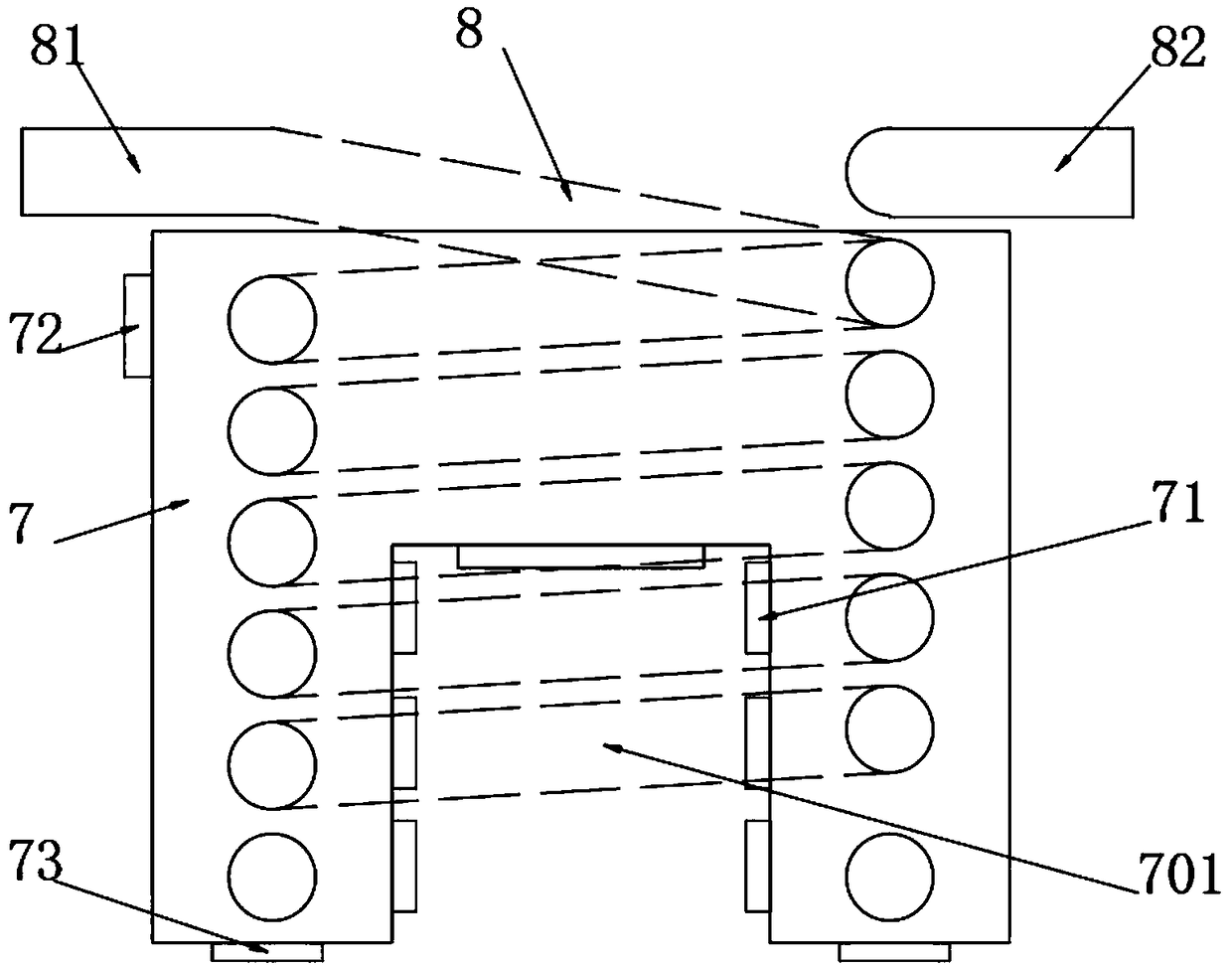

[0025] see Figure 1-3 , the present invention provides a technical solution: a tubular reactor for 3-hydroxytetrahydrofuran, comprising: a material storage device, which includes a malic acid solution batching tank 1 and a sodium borohydride suspension batching tank 2; a controllable Feeding device, the controllable feeding device includes a signal-connected PLC controller 3, an output pump 4 and a flow meter 5, the PLC controller 3 has a signal input terminal 31 and a signal output terminal 32, an output pump 4 and a flow meter 5 All are installed on the feeding pipes of the malic acid solution batching tank 1 and the sodium borohydride suspension batching tank 2, the output end of the flow meter 5 is connected to the signal input end 31, and the output end of the output pump 4 is connected to the signal output end 32 On: mixing device, mixing device comprises material mixer 6, and material mixer 6 is connected at the end of malic acid solution batching tank 1 and sodium bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com