Long-acting antibacterial solid lubricating film layer for space environment and preparation method thereof

A technology of solid lubrication and space environment, applied in coating, vacuum evaporation plating, metal material coating technology, etc., can solve the problems of antibacterial effect decline, less Ag reserves, and exhaustion of Ag elements, etc., and achieve good application prospects , The effect of not reducing the antibacterial level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

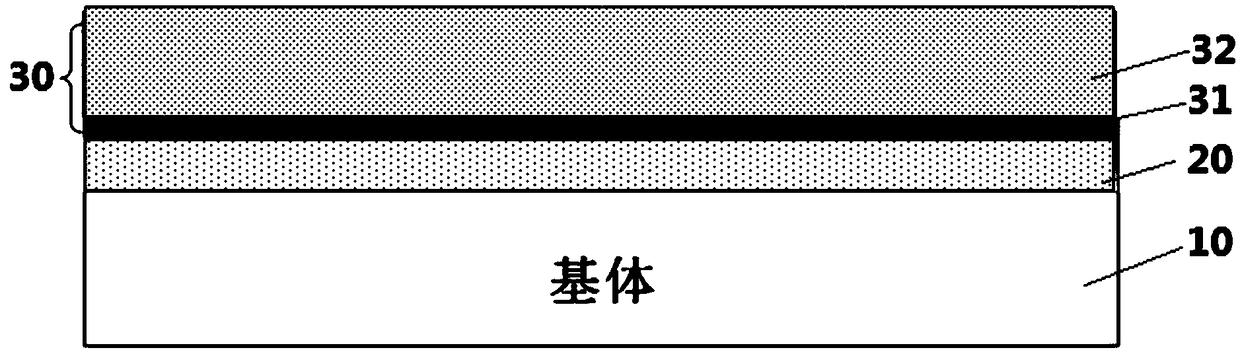

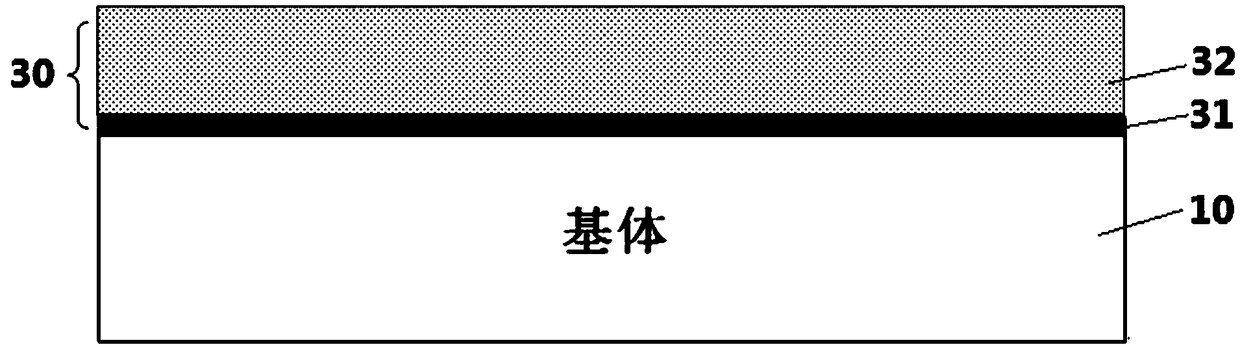

Method used

Image

Examples

Embodiment 1

[0025] In the present embodiment, the preparation process of substrate surface coating is as follows:

[0026] (1) The TC4 titanium alloy substrate was ultrasonically cleaned with acetone for 15 minutes and dried, placed on the rack, and placed in the deposition equipment, and vacuumed to 3.0×10 -3 Below Pa, fill the cavity with high-purity argon gas, and perform Ar plasma etching and cleaning on the substrate with a bias voltage of -350V for 30 minutes.

[0027] (2) Deposit a layer of metal Cr as a seed layer on the substrate by DC magnetron sputtering, the argon gas pressure is 4mTorr, the bias voltage is -90kv, and the thickness of the seed layer is about 200nm.

[0028] (3) DC magnetron co-sputtering graphite target and Ag target, depositing Ag-C lubricating antibacterial functional layer: graphite target sputtering current 20A, voltage about 500V; metal Ag target sputtering current reduced from 2A to 0.1A, working gas It is Ar gas, the working pressure is 0.2Pa, the depo...

Embodiment 2

[0032] The preparation process in this embodiment is basically the same as in Example 1, and the preparation process of the substrate surface coating is basically the same as in Example 1, except that the heat treatment temperature in step (4) is 300 ° C, and the heat treatment time is 0.5 Hour.

[0033] The obtained coating is tested according to the provisions of GJB3032-97. When the film layer is rubbed against a G10 grade 9Cr18 steel ball with a diameter of 1.5mm by a ball-disk friction and wear tester, the friction coefficient is 0.10, and the sliding friction life is 7.0×10 5 r. The hardness of the coating measured by the nano-indentation method was 25GPa, and the adhesion force of the coating measured by the scratch method was 33N. The coating is tested according to GJB150.10A, the film layer has passed the 84d mold test, and the rating does not exceed level 1. After the fungus test, according to GJB2502.5-2006, carry out ultraviolet radiation treatment, after 3000ESH...

Embodiment 3

[0035] In this embodiment, the substrate is the same as in Embodiment 1. The preparation process of the substrate surface coating is basically the same as in Example 1, except that the sputtering current of the Ag target in step (3) is reduced from 2A to 1A, and the total thickness of the coating is 5 μm. The heat treatment temperature is 200° C., and the heat treatment time is 20 hours.

[0036] The obtained coating is tested according to the provisions of GJB3032-97. When the film layer is rubbed against a G10 grade 9Cr18 steel ball with a diameter of 1.5mm by a ball-disk friction and wear tester, the friction coefficient is 0.13 and the sliding friction life is 6.5×10 5r. The coating hardness measured by the nano-indentation method is 22GPa, and the coating adhesion force measured by the scratch method is 35N. The coating is tested according to GJB150.10A, the film layer has passed the 84d mold test, and the rating does not exceed level 1. After the fungus test, accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com