Lactobacillus plantarum-enriched low-temperature long-time fermented milk and preparation method thereof

A technology of Lactobacillus plantarum and fermented milk, which is applied in the direction of Lactobacillus, dairy products, and other dairy products, and can solve the problems of inability to grow, limit the large-scale application of fermented dairy products, and poor flavor of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Specific steps are as follows:

[0087] (1) Take raw materials according to Table 1;

[0088] (2) According to the ratio in Table 1, premix the sweetener, thickener, emulsifier and compound fruit and vegetable juice first, then dissolve the obtained premix in raw milk at 40°C, slowly add food flavor, Stir for 30 minutes, and mix well to obtain material liquid A;

[0089] (3) Homogenize the material liquid A, wherein the first-stage homogenization pressure is 15MPa, the second-stage homogenization pressure is 5MPa, and the homogenization temperature is 60°C. After homogenization, sterilize at 85°C for 10 minutes, and then cool to 30°C. Feed liquid B;

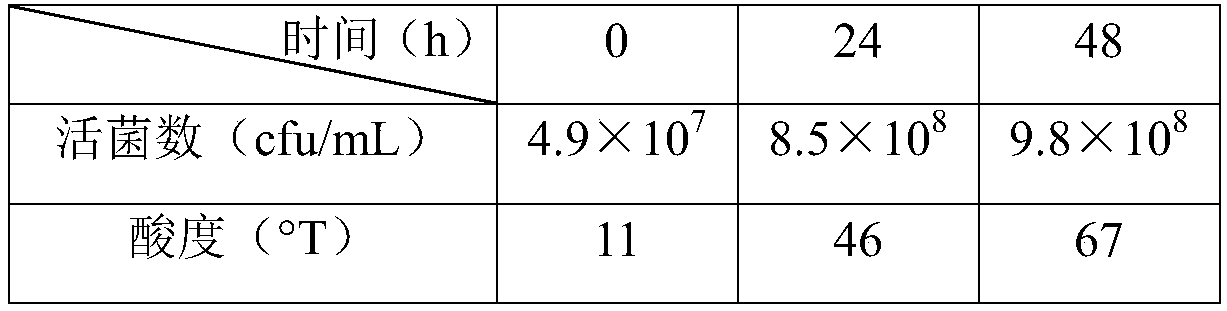

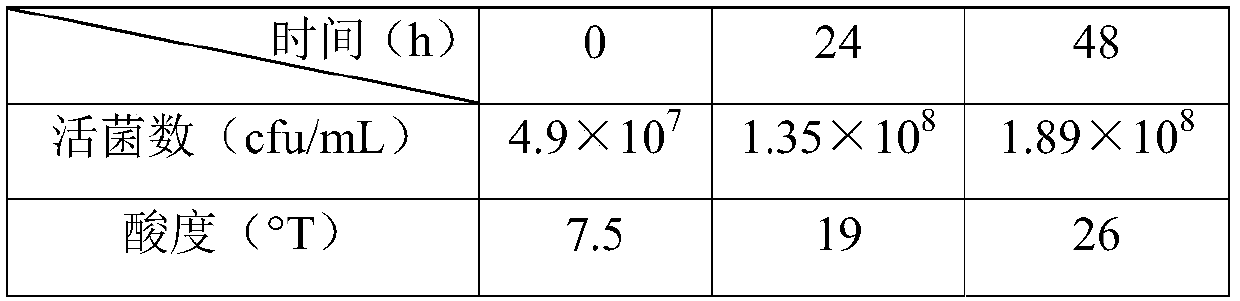

[0090] (4) Inoculate Lactobacillus plantarum CGMCC No.5494 in feed liquid B, inoculum size 5.0×10 7 CFU / mL, the inoculation temperature is 30°C, after stirring and mixing at 200r / min for 5min, ferment at 30°C until the terminal acidity is 65°T, the fermentation time is 96h, and the feed liquid C is obtained;

[0091] (...

Embodiment 2

[0101] Specific steps are as follows:

[0102] (1) Take raw materials according to Table 4;

[0103] (2) According to the ratio in Table 4, firstly premix the sweetener, thickener, emulsifier and compound fruit and vegetable juice, then dissolve the obtained premix in raw milk at 55°C, slowly add food flavor, Stir for 15 minutes, and mix well to obtain material liquid A;

[0104] (3) Homogenize the material liquid A, wherein the first-stage homogenization pressure is 18MPa, the second-stage homogenization pressure is 2MPa, and the homogenization temperature is 70°C. After homogenization, sterilize at 95°C for 10 minutes, and then cool to 37°C. Feed liquid B;

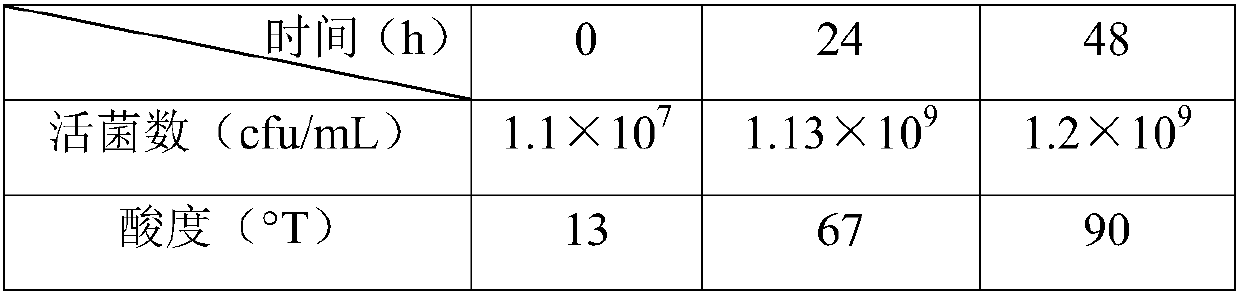

[0105] (4) Inoculate Lactobacillus plantarum CGMCC No.5494 in feed liquid B, inoculum size 1.1×10 7 CFU / mL, the inoculation temperature is 37°C, after stirring and mixing at 100r / min for 5min, ferment at 37°C until the terminal acidity is 75°T, the fermentation time is 24h, and the feed liquid C is obtained;

[0106]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Titrated acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com