Light-weight phase change aerated concrete, building body wall and construction method of building body wall

A technology of air-entrained concrete and lightweight phase, applied in walls, building components, buildings, etc., can solve the problems of automatic air conditioning, low thermal conductivity of still air, and difficulty in preventing heat conduction, so as to improve timeliness and prevent cracking Effects of performance improvement and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The raw material formula and weight parts of the lightweight phase change aerated concrete block are:

[0042] 40 parts of fly ash, 12 parts of vitrified microspheres, 10 parts of paraffin powder containing graphite, 13 parts of quicklime, 11 parts of cement, 2 parts of gypsum, 0.1 part of aluminum powder, 0.01 part of polypropylene fiber, 0.6 part of water reducer, 0.2 part of polyacrylamide, 1 part of stearic acid and appropriate amount of water.

Embodiment 2

[0044]38 parts of fly ash, 11 parts of vitrified microspheres, 11 parts of paraffin powder containing graphite, 12 parts of quicklime, 10 parts of cement, 2 parts of gypsum, 0.1 part of aluminum powder, 0.01 part of polypropylene fiber, 0.4 part of water reducer, 0.2 parts of polyacrylamide, 2 parts of stearic acid and appropriate amount of water.

Embodiment 3

[0046] 35 parts of fly ash, 16 parts of vitrified microbeads, 12 parts of paraffin powder containing graphite, 14 parts of quicklime, 13 parts of cement, 3 parts of gypsum, 0.1 part of aluminum powder, 0.01 part of polypropylene fiber, 0.5 part of water reducer, 0.2 parts of polyacrylamide, 3 parts of stearic acid and appropriate amount of water.

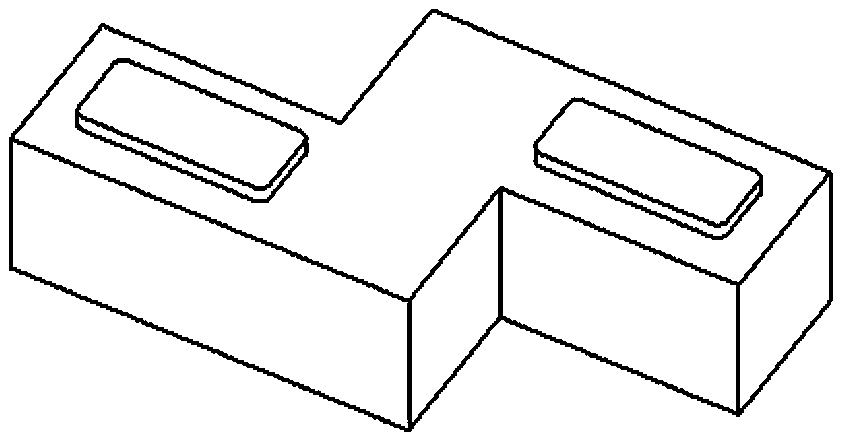

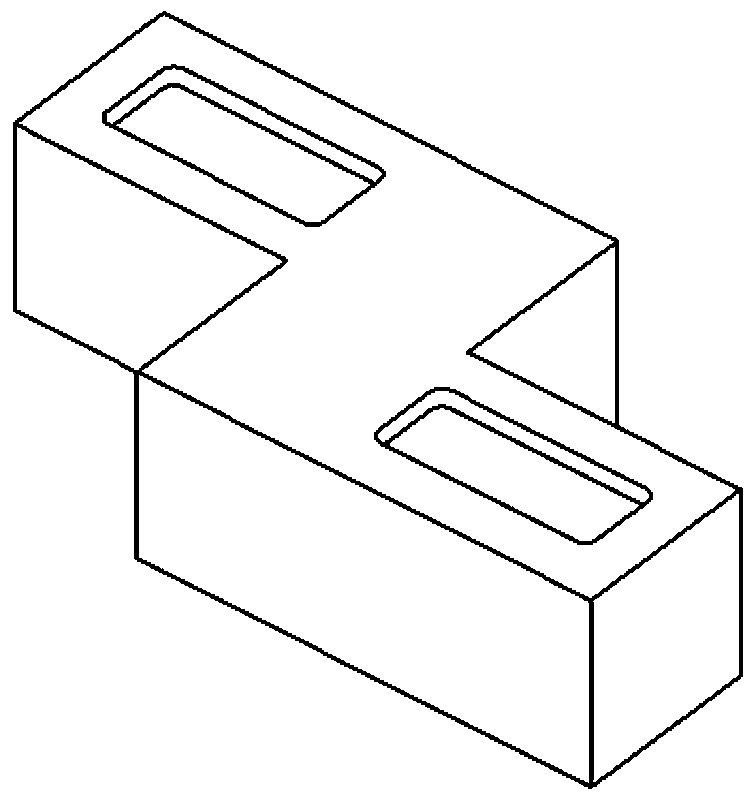

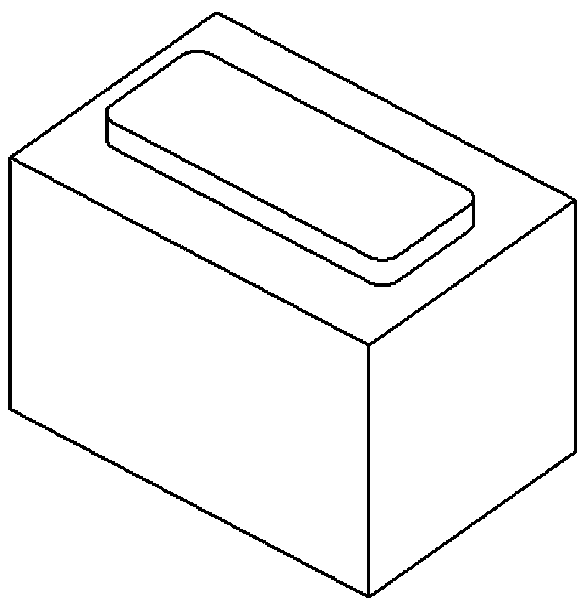

[0047] The lightweight phase-change aerated concrete masonry wall prepared by using the above-mentioned concrete is characterized in that: it includes a Z-shaped structure main body, a cuboid structure ligand and a mortar layer; the Z-shaped structure main body is arranged in the middle part of the masonry wall, The cuboid structure ligands are arranged at the ends of both sides of the masonry wall; the upper end surface of the Z-shaped structure main body is provided with a block-shaped protrusion structure, and the corresponding bottom position is provided with a size corresponding to the block-shaped protrusion structure. Corresp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com