Bottom-surface-in-one coating, preparation method thereof, gloss adjustment method and application thereof

A paint and bottom surface technology, which is applied in the field of bottom-surface-integrated paint and its preparation, can solve the problems of inability to take into account the performance and gloss of the bottom-surface-integrated paint, and the cumbersome formula design, so as to achieve considerable aesthetic value, enhance aesthetic value, and improve gloss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The preparation method of the bottom-surface-integrated coating of the present embodiment comprises the following steps:

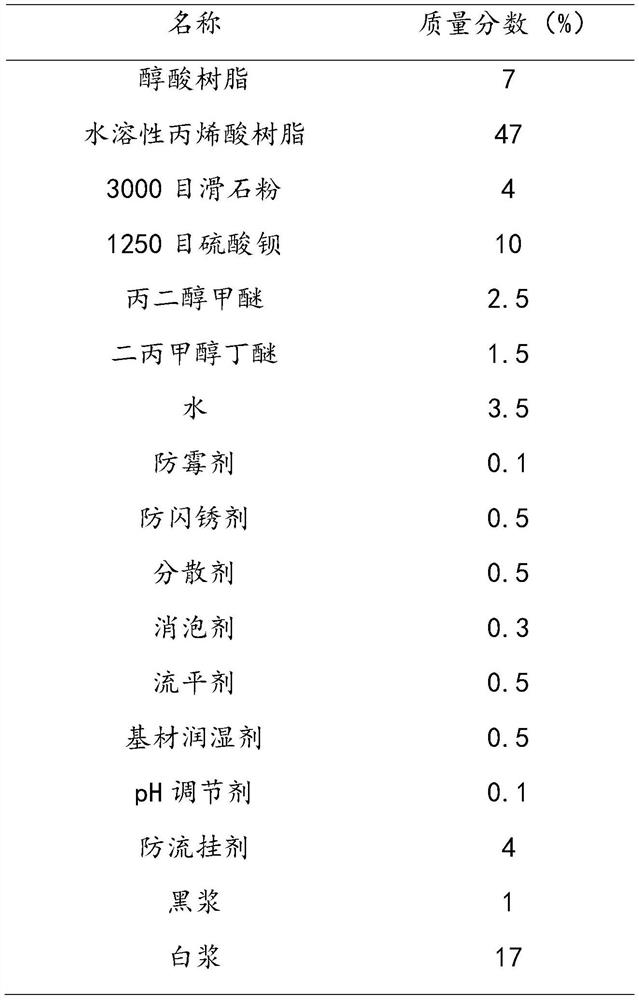

[0076] (1) Weigh the raw materials according to the weight ratio in the table

[0077]

[0078] (2) Mix the alkyd resin and the water-soluble acrylic resin evenly under the rotating speed of 800 rpm / min, add dispersant and defoamer, add 3000 mesh talcum powder and 1250 mesh barium sulfate, then add propylene glycol methyl ether, For the mixture of dipropylmethanol butyl ether and water, increase the stirring speed to 1500rpm / min, and stir at high speed for 30min;

[0079] (3) Reduce the stirring speed to 1000-1200rpm / min, add a pH regulator to the material obtained in step (2) to adjust the pH value to 8.0-8.5, and then add the remaining auxiliary agents and color paste (black pulp, white slurry), stirred at a rotating speed of 1000-1200rpm / min for 5-10min to obtain base material;

[0080] (4) Then take the base material, according to the weigh...

Embodiment 2

[0082] The preparation method of the bottom-surface-integrated coating of the present embodiment comprises the following steps:

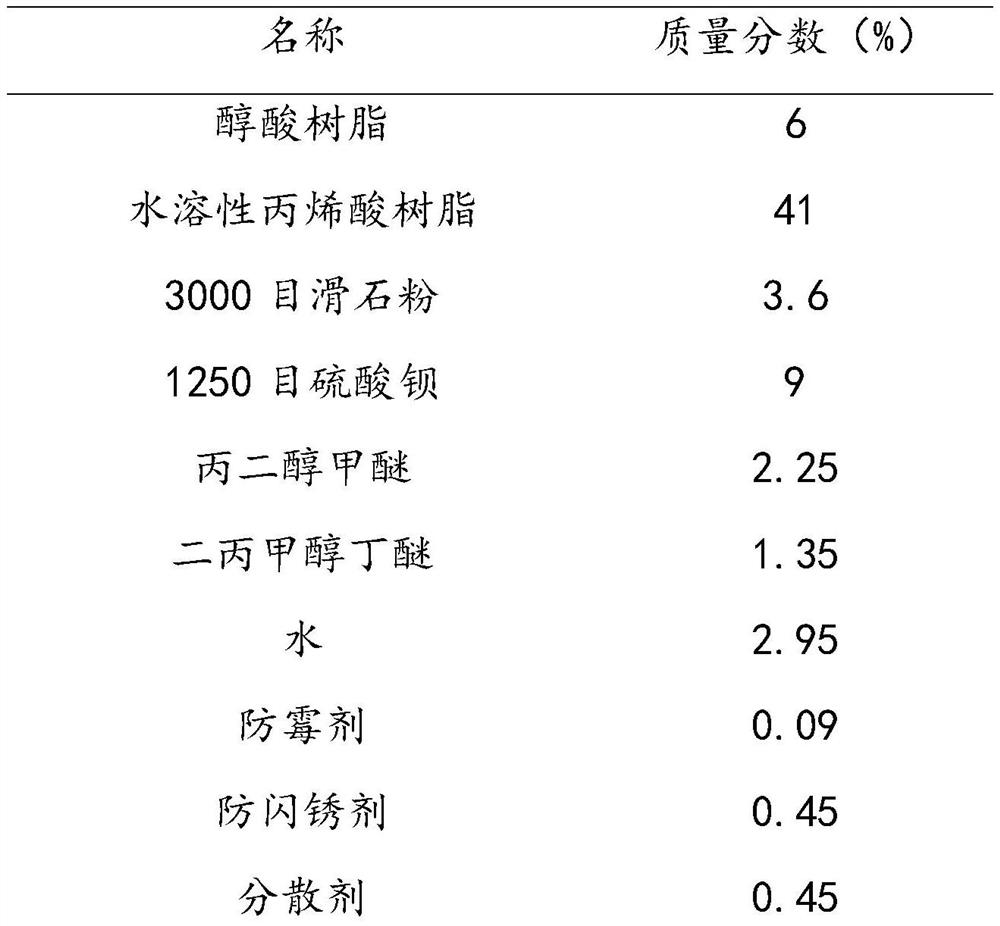

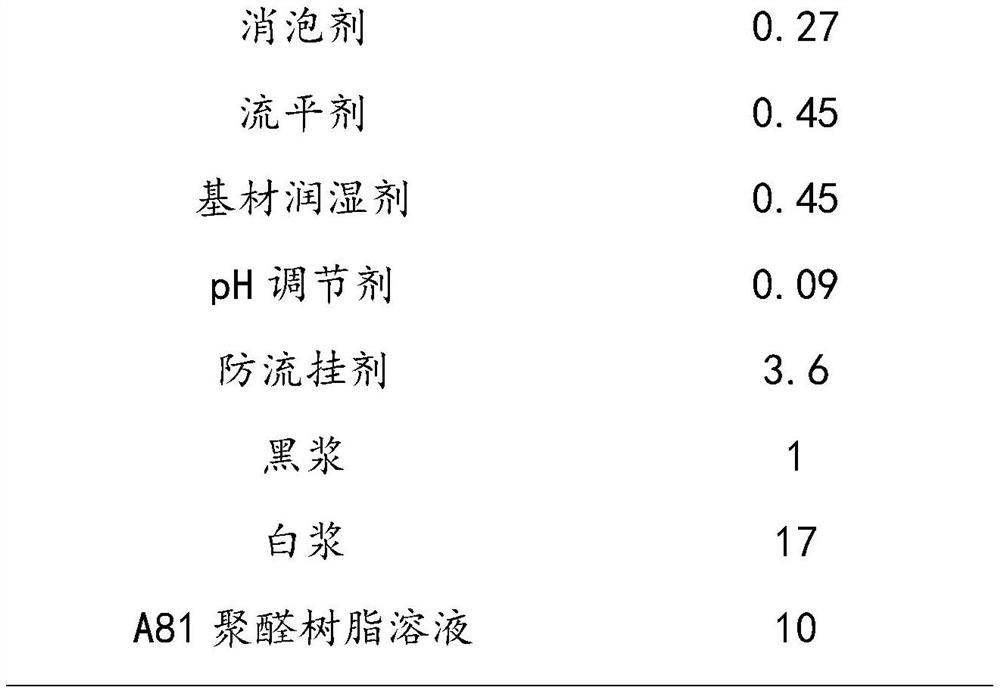

[0083] (1) Weigh the raw materials according to the weight ratio in the table

[0084]

[0085]

[0086] Among them, the preparation method of the A81 polyaldehyde resin solution is: mix 95% vol ethanol aqueous solution and ethyl acetate in a mass ratio of 1:1 to make a composite solvent, and set aside; take 400g of the composite solvent and put it in a dispersion tank, Add 600g of solid polyaldehyde resin A81 while stirring, stir at room temperature for 30 minutes, seal and stand still to obtain A81 polyaldehyde resin solution;

[0087] (2) Mix the alkyd resin and the water-soluble acrylic resin evenly under the rotating speed of 800 rpm / min, add dispersant and defoamer, add 3000 mesh talcum powder and 1250 mesh barium sulfate, then add propylene glycol methyl ether, For the mixture of dipropylmethanol butyl ether and water, increase the sti...

Embodiment 3

[0091] The preparation method of the bottom-surface-integrated coating of the present embodiment comprises the following steps:

[0092] (1) Weigh the raw materials according to the weight ratio in the table

[0093]

[0094] Among them, the preparation method of the A81 polyaldehyde resin solution is: mix 95% vol ethanol aqueous solution and ethyl acetate in a mass ratio of 1:1 to make a composite solvent, and set aside; take 400g of the composite solvent and put it in a dispersion tank, Add 600g of solid polyaldehyde resin A81 while stirring, stir at room temperature for 30 minutes, seal and stand still to obtain A81 polyaldehyde resin solution;

[0095] (2) Alkyd resin and water-soluble acrylic resin are mixed evenly under the rotating speed of mechanical stirring 800rpm / min, then add the mixed solution of propylene glycol methyl ether, dipropylmethanol butyl ether, water and stir for 10min, stir evenly;

[0096] (3) Add a pH regulator to the material obtained in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com