Electronic cigarette film heating sheet

A technology of electronic cigarettes and heating sheets, which is applied in the field of low-power heating devices, can solve the problems of non-full coverage of resistance circuit patterns, residual tar absorbed by heating sheets, and uneven width of resistance lines, etc., to achieve good heat conduction and better heating effect , The effect of reducing the difficulty of circuit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

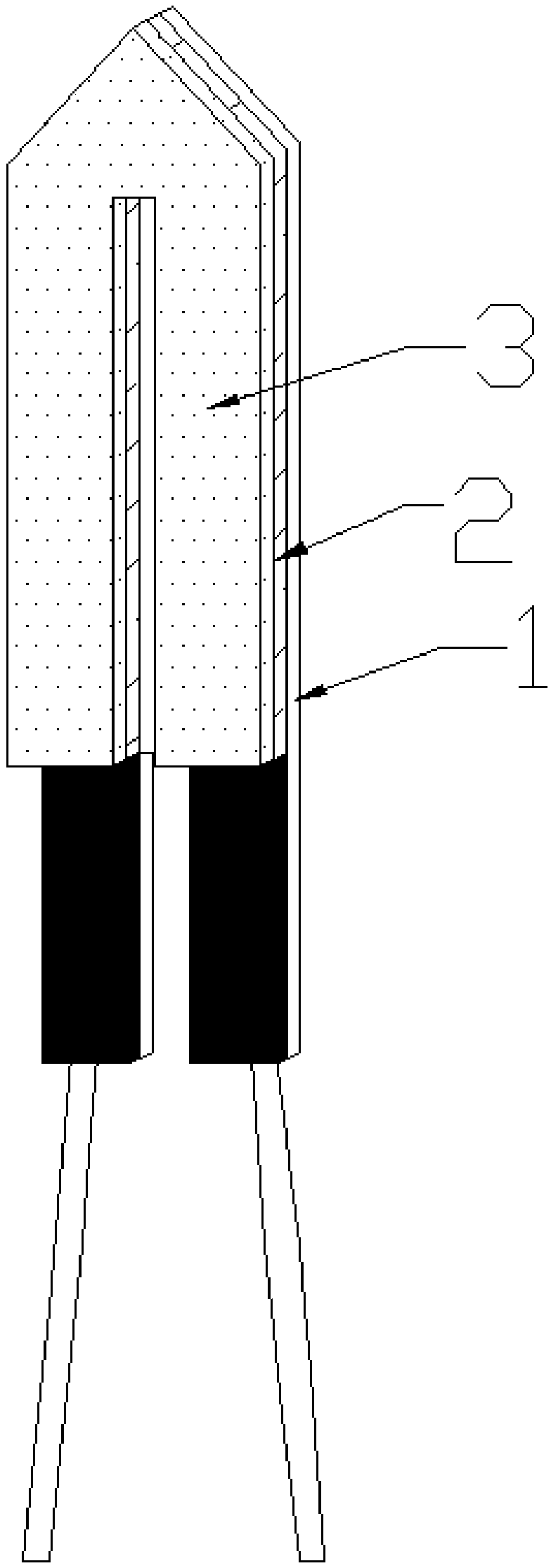

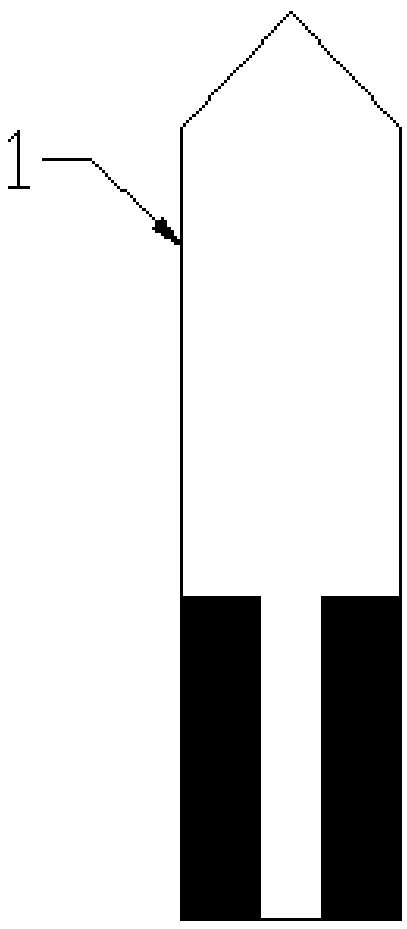

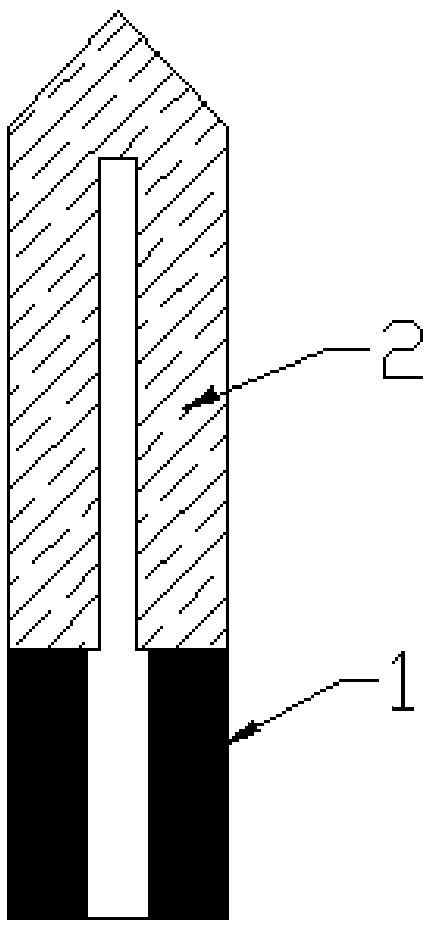

[0038] Such as Figure 1-3 As shown, an electronic cigarette film heating sheet includes a ceramic bare chip 1 made of zirconia or aluminum oxide, and the outside of the ceramic bare chip 1 is coated with a heating resistance film layer 2 by vapor deposition technology, and the heating resistance film layer 2 The thickness is less than 2 μm, and the heating resistance film layer 2 is coated with a three-proof protective film layer 3 by vapor deposition technology; the raw materials for the heating resistance film layer 2 include silver, copper, aluminum, gold, etc., and the materials are all low resistivity (less than 5Ω.m) and a metal material with a positive temperature coefficient of resistance (TCR>0); the heating resistance film layer (2) may include a transition layer, which is zirconia (ZrO2), aluminum oxide (Al2O3), nickel (Ni) , one of chromium (Cr), and the thickness of the transition layer does not exceed 100nm.

[0039] The manufacturing method of the heating resi...

Embodiment 2

[0045] Such as Figure 1-4 As shown, the raw materials for the three-proof protective film layer 3 are silicon dioxide (SiO2), silicon nitride (SiN) and silicon carbide (SiC), and the three-proof protective film layer 3 has a single-layer structure, and the single-layer structure is high Hardness, anti-oxidation, and high-temperature-resistant film layer; the three-proof protective film layer 3 is a double-layer structure, one layer is a high-hardness, anti-oxidation, and high-temperature-resistant protective layer, and the other layer is an oleophobic and hydrophobic lubricating layer.

[0046] The production method of the three-proof protective film layer 3:

[0047] S1. According to different vapor deposition methods, a high-hardness, high-temperature-resistant inorganic compound can be selected as the material of the three-proof protective film, such as silicon dioxide (SiO2), silicon nitride (SiN) and silicon carbide (SiC), etc. Wait;

[0048] S2. In order to enhance th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com