Improved SDA semi-dry desulfurization tower

A semi-dry desulfurization and desulfurization tower technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as high investment and operating costs, equipment corrosion, and large equipment, and achieve strong adaptability to working conditions. , small pressure loss, no desulfurization blind area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

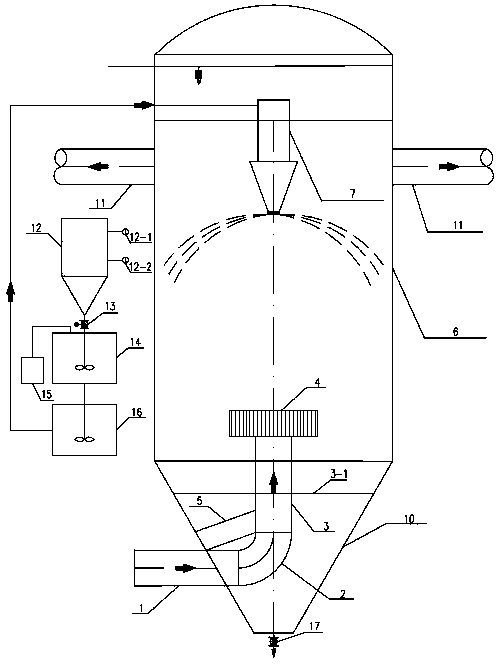

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

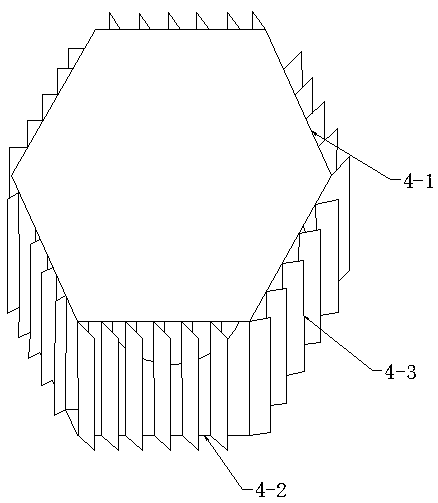

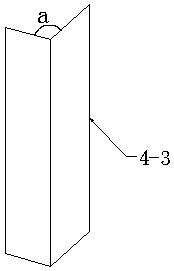

[0021] see figure 1 and 2 , an improved SDA semi-dry desulfurization tower of the present invention, comprising a desulfurization tower shell 6 and a desulfurizing agent supply mechanism, the bottom of the desulfurization tower shell 6 is connected with a conical ash hopper 10 with a chamfer of 60°, the desulfurization tower A rotary atomizer 7 and a regular hexagonal smoke distributor 4 are respectively installed at the top and bottom of the housing 6 .

[0022] The bottom of the regular hexagonal flue gas distributor 4 is connected to the flue gas inlet pipe 1 through the flue gas conveying pipeline. The flue gas conveying pipeline includes a vertical pipe 3 and a 90° elbow 2, and the vertical pipe 3 is fixed by a steel structure bracket 3-1 In the tapered ash hopper 10, its top communicates with the middle part of the regular hexagon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com