Smoke gas denitration device for combustion machine

A technology of denitrification and gas turbine, which is applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of direct emission of flue gas from gas turbines, and achieve the effect of sufficient reaction, thorough reaction, and uniform and smooth flow of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

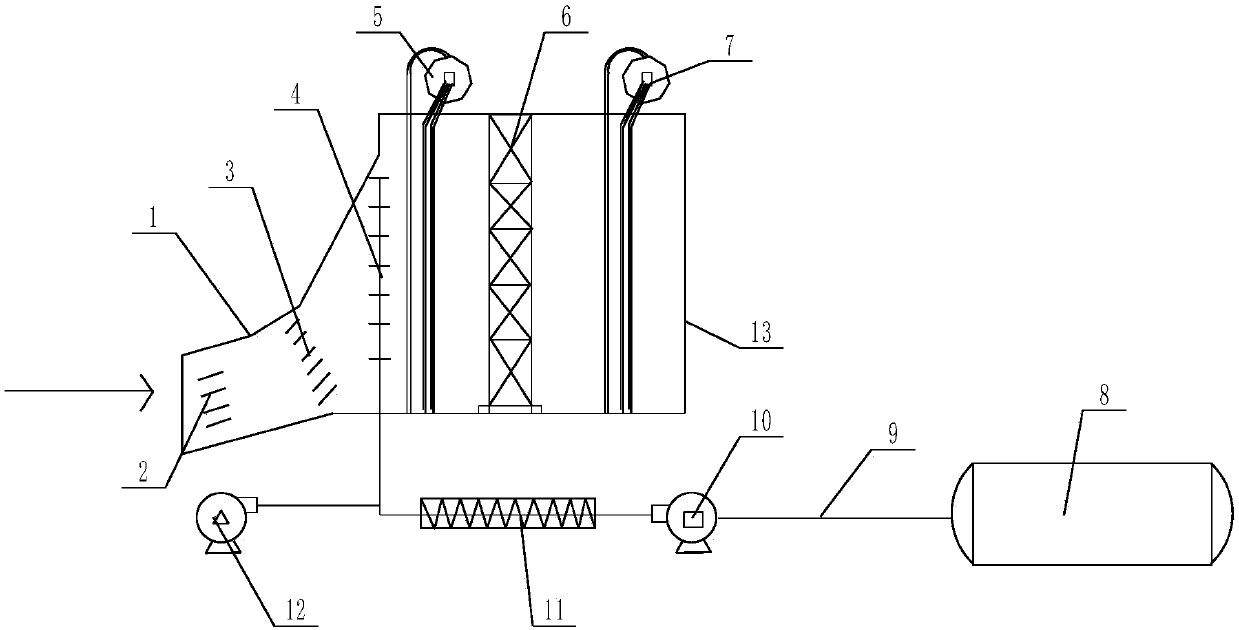

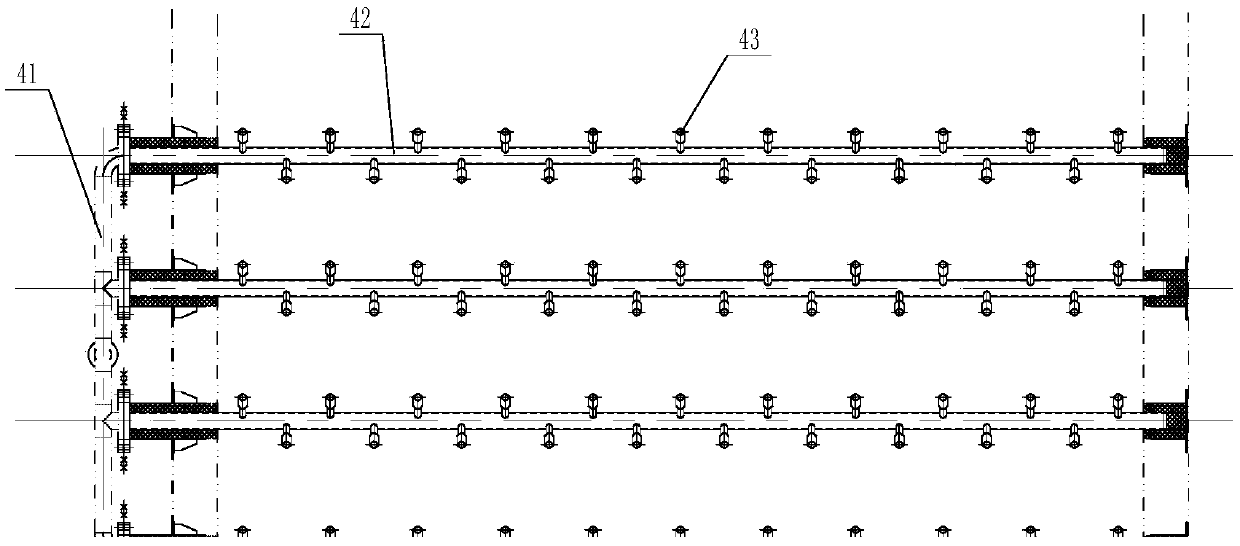

[0021] Such as Figure 1-2 As shown, the gas turbine flue gas denitrification device according to the present invention includes a denitrification reaction device and an ammonia gas delivery device;

[0022] The denitration reaction device includes a reaction shell 13, an ammonia injection grid 4, a heat exchanger 5, and a denitration catalyst module 6; the front end of the reaction shell is connected to the flue 1 of the gas turbine waste heat boiler, and the flue gas flows into the denitration reaction according to the flow direction After the installation, it is discharged after passing through the ammonia injection grid, heat exchanger, and denitration catalyst module;

[0023] The ammonia water delivery device includes an ammonia water storage tank 8, an ammonia water delivery pipe 9, an ammonia water delivery pump 10, an ammonia evaporator 11, and a dilution fan 12; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com