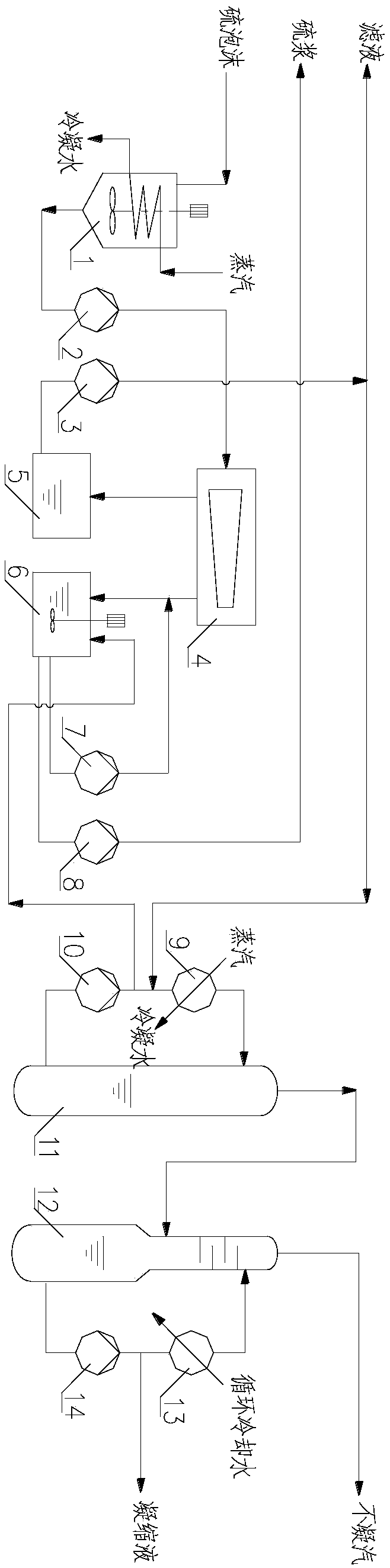

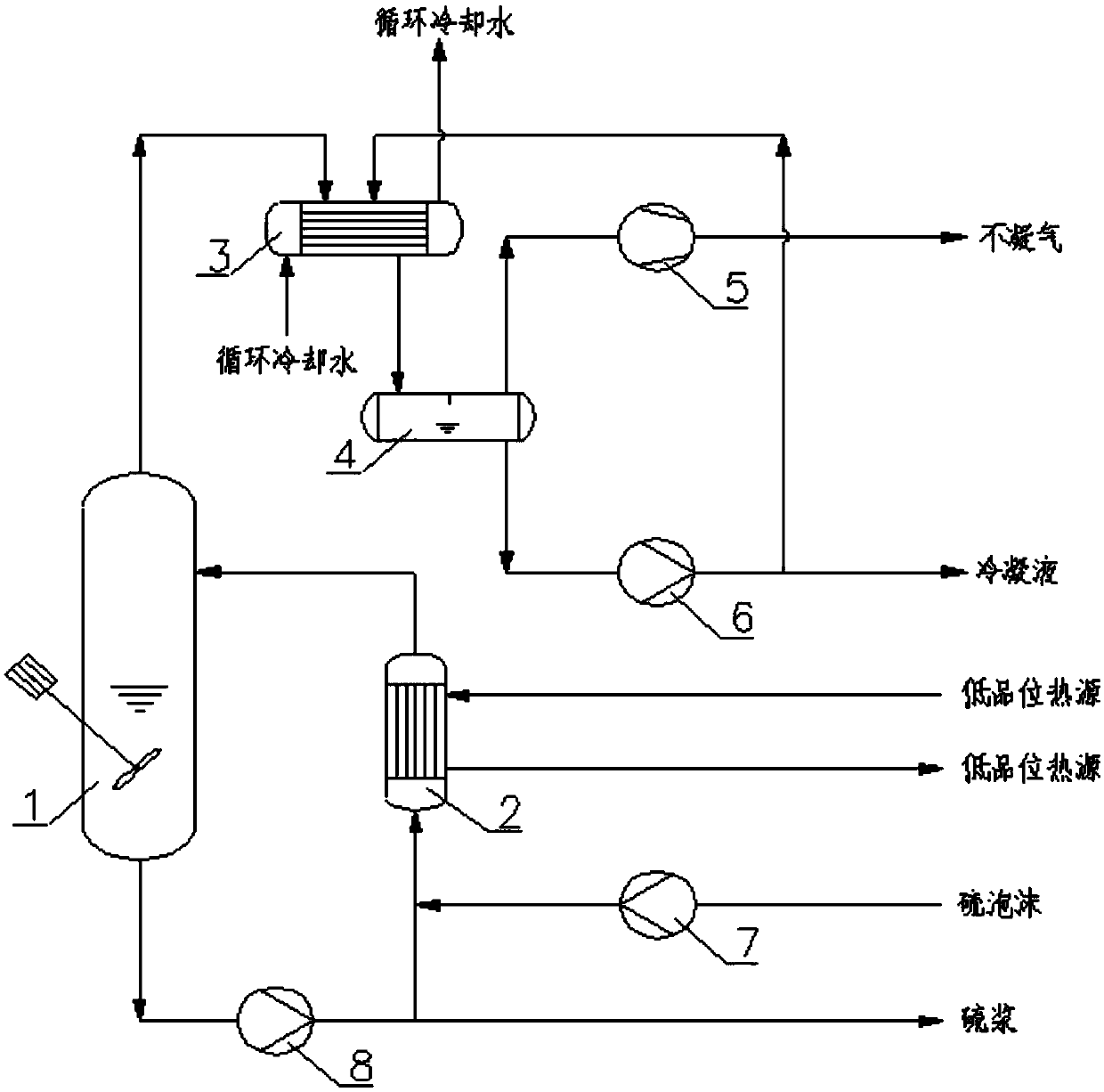

Technology and device for preparing sulfur pulp by performing vacuum evaporation treatment on coked sulfur foams

A technology of vacuum evaporation and coking sulfur, applied in the chemical industry, sustainable manufacturing/processing, inorganic chemistry, etc., can solve the problems of reducing heat exchange efficiency, melting of suspended sulfur, and high operating costs, reducing heat exchange efficiency, saving energy and reducing costs. The effect of good arrangement and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The sulfur foam at the top of the regeneration tower of the desulfurization unit is directly sent to the sulfur slurry circulating liquid pipeline in front of the circulating liquid heater 2 after being pressurized by the foam pump 7, and then sent to the vacuum evaporation tower 1 for evaporation after being heated by circulating ammonia water. Excess water is produced, and a small amount of ammonia is also evaporated at the same time, and the unevaporated component is sulfur slurry. In the circulating fluid heater 2, the temperature of the mixed circulating fluid is heated from 50-55°C to 65°C, and the temperature of the circulating ammonia water is cooled from 75-80°C to 65°C. The vacuum degree of the vacuum evaporation tower 1 is controlled at 85.6KPa, and the corresponding operating temperature is 55°C. In order to prevent the precipitation of suspended sulfur in the vacuum evaporation tower 1 and the precipitation of ammonium salt crystallization due to excessive ...

Embodiment 2

[0044] The sulfur foam at the top of the regeneration tower of the desulfurization unit is directly sent to the sulfur slurry circulating liquid pipeline in front of the circulating liquid heater 2 after being pressurized by the foam pump 7, and then sent to the vacuum evaporation tower 1 for evaporation after being heated by absorbing acid. Excess water is produced, and a small amount of ammonia is also evaporated at the same time, and the unevaporated component is sulfur slurry. In the circulating fluid heater 2, the temperature of the mixed circulating fluid is heated from 55 to 60°C to 75°C, and the temperature of the absorption acid is cooled from 90 to 100°C to 70°C. The vacuum degree of the vacuum evaporation tower 1 is controlled at 81.4KPa, and the corresponding operating temperature is 60°C. In order to prevent the precipitation of suspended sulfur in the vacuum evaporation tower 1 and the precipitation of ammonium salt crystallization due to excessive local concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com