Synthesis method of SSZ-13 molecular sieve

A synthesis method and molecular sieve technology, applied in the direction of separation methods, molecular sieve catalysts, including molecular sieve catalysts, etc., can solve problems such as poor catalytic activity, particle agglomeration, poor dispersion, etc., to reduce tail gas treatment costs, increase yield, The effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

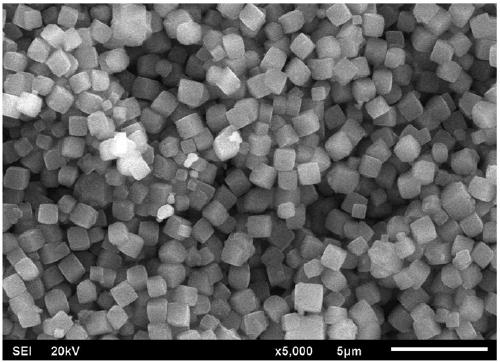

[0058] The present embodiment provides a kind of synthetic method of SSZ-13 molecular sieve, comprises the following steps:

[0059] 1) Pretreatment of seed crystals: pretreat SSZ-13 molecular sieve seeds, specifically: take the finished SSZ-13 molecular sieve seeds, make slurry according to the material-to-water ratio of 1:3, and pass through the mechanical Pulverize and ultrasonically disperse to obtain seed crystals with a particle size of D50=0.236;

[0060] 2) Silicon source pretreatment: the solid silicon source is turned into a powder that can pass through 300 mesh or have a bulk density less than or equal to 0.30 g / ml after passing through the gas powder;

[0061] 3) Add 414 grams of 9.5 mol / L ammonia solution to 2 L of aluminum chloride solution with a concentration of 0.26 mol / L, add pure water to dilute to 3 L, and press filter to obtain a primary precursor of aluminum hydroxide; body, add pure water to make a slurry and dilute to 3L, press filter to obtain the sec...

Embodiment 2

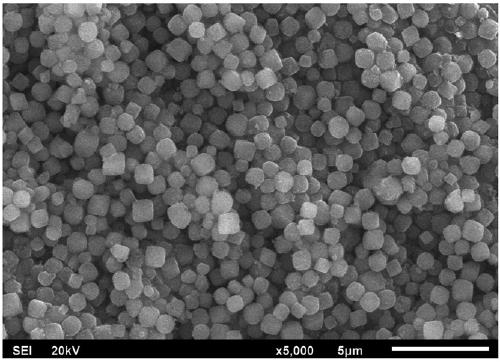

[0068] The present embodiment provides a kind of synthetic method of SSZ-13 molecular sieve, comprises the following steps:

[0069] 1) seed crystal pretreatment: with embodiment 1;

[0070] 2) silicon source pretreatment: with embodiment 1;

[0071] 3) Add 765 grams of 9.5 mol / L ammonia solution to 2 L of aluminum chloride solution with a concentration of 0.48 mol / L, add pure water to dilute to 3 L, and press filter to obtain a primary precursor of aluminum hydroxide; body, add pure water to make a slurry and dilute to 3L, press filter to obtain the secondary precursor of aluminum hydroxide, and obtain the tertiary precursor in the same way.

[0072] 4) Add the aluminum hydroxide precursor to 3L of pure water for beating, perform ultrasonic dispersion treatment, control the ultrasonic frequency to 30KHz, and ultrasonic for 12 minutes; add 134 grams of amantadine hydrochloride as a template agent, and continue ultrasonic for 10 minutes; obtain Contains aluminum hydroxide col...

Embodiment 3

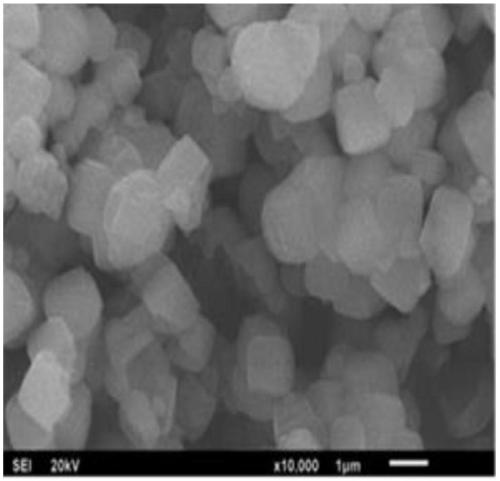

[0078] The present embodiment provides a kind of synthetic method of SSZ-13 molecular sieve, comprises the following steps:

[0079] 1) seed crystal pretreatment: with embodiment 1;

[0080] 2) silicon source pretreatment: with embodiment 1;

[0081] 3) Add 1275 grams of 9.5 mol / L ammonia solution in 2 L of aluminum chloride solution with a concentration of 0.80 mol / L, add pure water to dilute to 3.5 L, and press filter to obtain a primary precursor of aluminum hydroxide; For the precursor, add pure water to beat and dilute to 3.5L, press filter to obtain the secondary precursor of aluminum hydroxide, and similarly prepare the tertiary precursor.

[0082] 4) Add the aluminum hydroxide precursor to 3L of pure water for beating, perform ultrasonic dispersion treatment, control the ultrasonic frequency to 20KHz, and ultrasonic for 20 minutes; add 89 grams of amantadine hydrochloride as a template, and continue ultrasonic for 10 minutes; obtain Contains aluminum hydroxide colloi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com