Preparation method of tungsten-doped anatase nanometer titanium dioxide powder

A nano-titanium dioxide, anatase-type technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of large nanoscale titanium dioxide powder, repeatability of polluted environment, complex production process, etc. Achieve the effect of high repeatability, easy handling and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

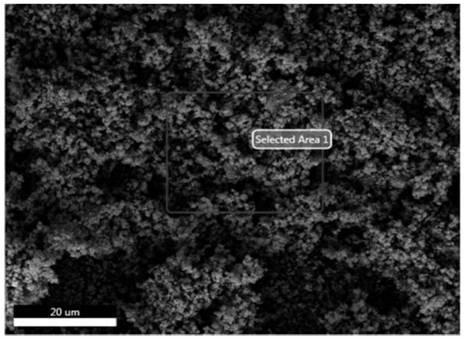

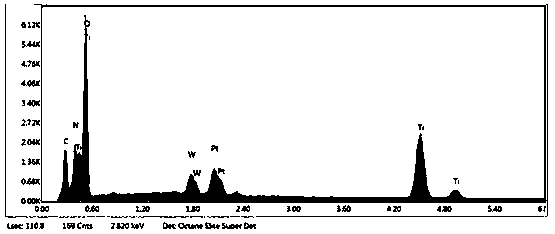

Image

Examples

Embodiment 1

[0031] The preparation method of the tungsten-doped anatase nano-titanium dioxide powder of the present invention adopts a high-temperature calcination method, and the specific preparation steps are as follows:

[0032] Under stirring, slowly add the concentrated sulfuric acid solution into distilled water along the wall for dilution to obtain a dilute sulfuric acid solution with a concentration of 5 mol / L;

[0033] Take 108 kg of dilute sulfuric acid solution of the above concentration, 4 The mass ratio of dilute sulfuric acid solution is 1:2 to take TiCl 4 54㎏, according to ammonium tungstate ((NH 4 ) 6 h 2 W 12 o 40 ) and TiCl 4 Take 6 kg of ammonium tungstate with a mass ratio of 1:9, and set aside;

[0034] Add the above-mentioned dilute sulfuric acid solution and TiCl in sequence to the reaction vessel 4 , stirred and mixed to obtain oxytitanic acid, TiCl 4 It is added slowly under the stirring state of a magnetic stirrer;

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is that ammonium tungstate and TiCl 4 According to the mass ratio of 1:3, the dilute sulfuric acid solution, TiCl 4 and ammonium tungstate ((NH 4 ) 6 h 2 W 12 o 40 ) are respectively 36 kg, 18 kg, and 6 kg, and all the other are identical to embodiment 1.

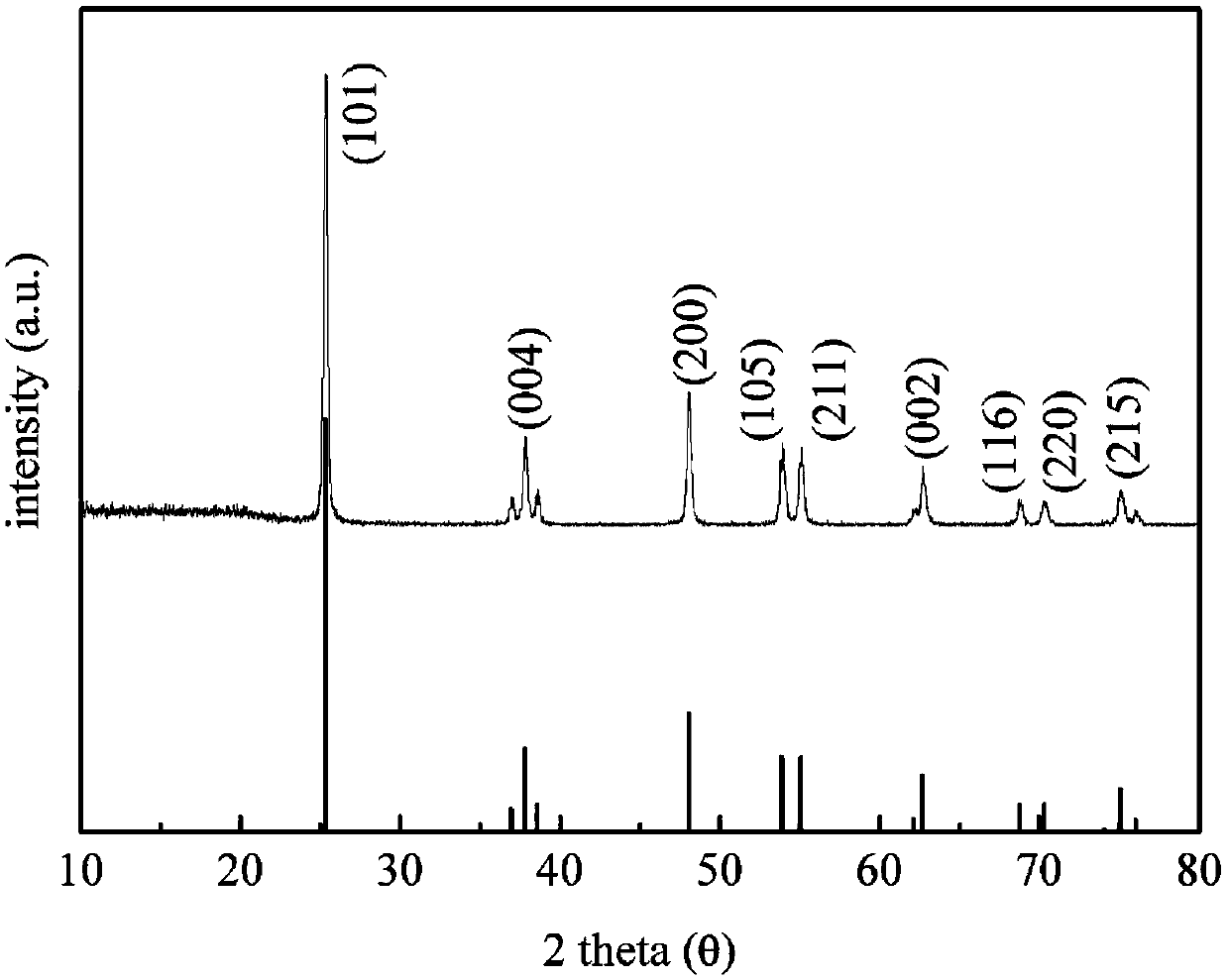

[0043] Figure 5 It is the XRD spectrum of the product prepared in this example, showing that the product is a pure phase.

Embodiment 3

[0045] The difference between this embodiment and embodiments 1 and 2 is that the ammonium tungstate and TiCl added in the reaction vessel 4 The mass ratio is 1:6, dilute sulfuric acid solution, TiCl 4 and ammonium tungstate ((NH 4 ) 6 h 2 W 12 o 40 ) added in amounts of 72kg, 36kg, and 6kg respectively

[0046] Figure 6 It is the XRD spectrum of the product of this example, no impurity peak appears, and it is a pure phase product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com