Recycling treatment method of high-ammonia-nitrogen wastewater

A technology of recycling and treatment methods, which is applied in the direction of biological treatment adjustment methods, water/sewage treatment, water treatment parameter control, etc., can solve problems such as high operating costs, system impact, and high pressure on corporate environmental protection, and reduce additional costs. Carbon source amount, avoiding sludge poisoning, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment relates to the recycling treatment of high ammonia nitrogen wastewater.

Embodiment 11

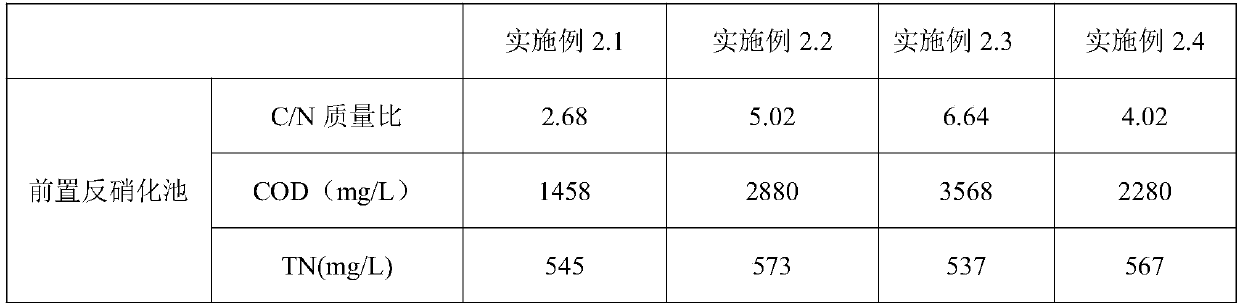

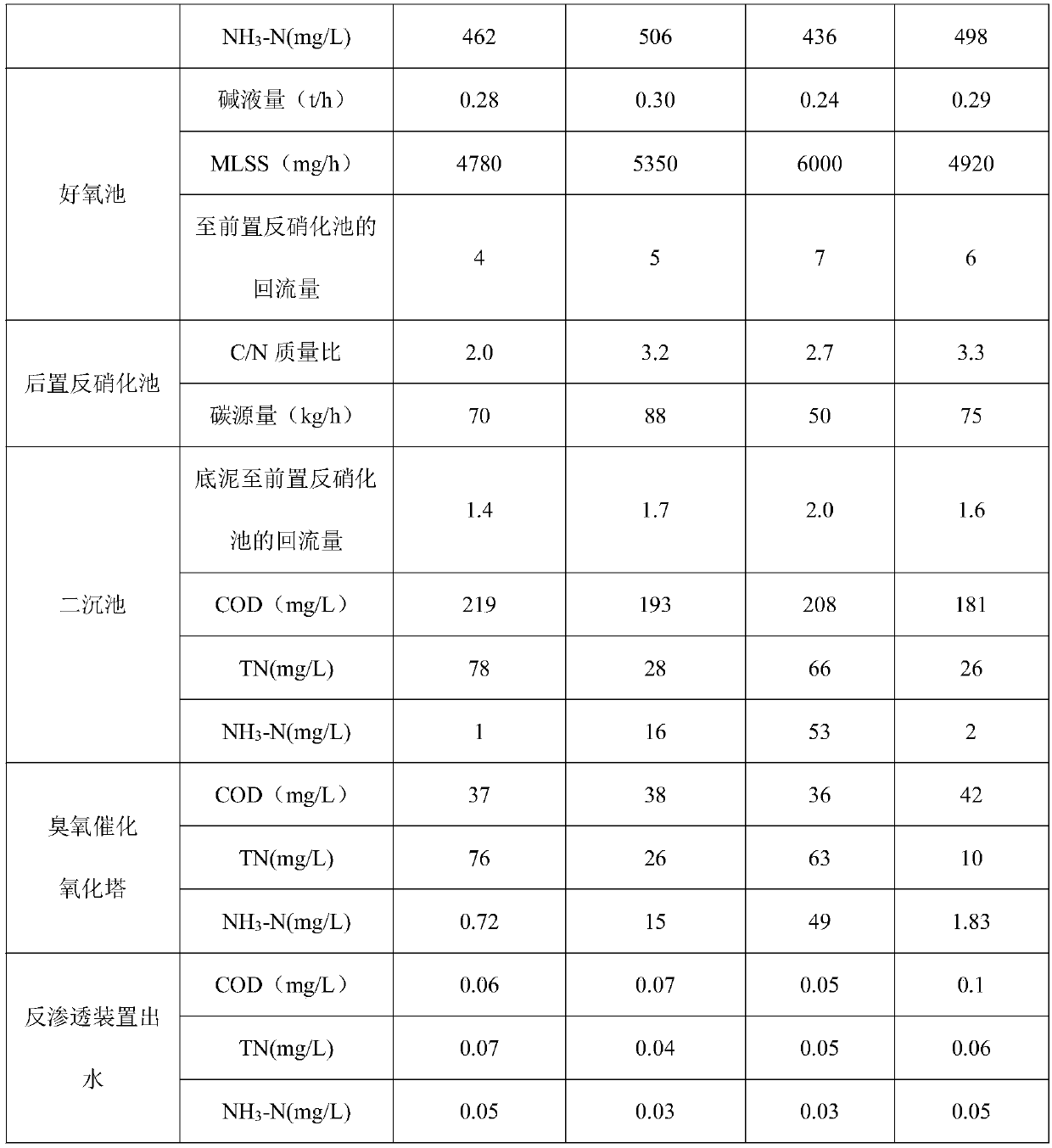

[0028] For the water inflow from the vitamin B12 production process is 240m 3 / h, TN concentration is 586mg / L, NH 3 - High ammonia nitrogen wastewater with a N concentration of 472mg / L and a COD concentration of 8640mg / L shall be treated as follows:

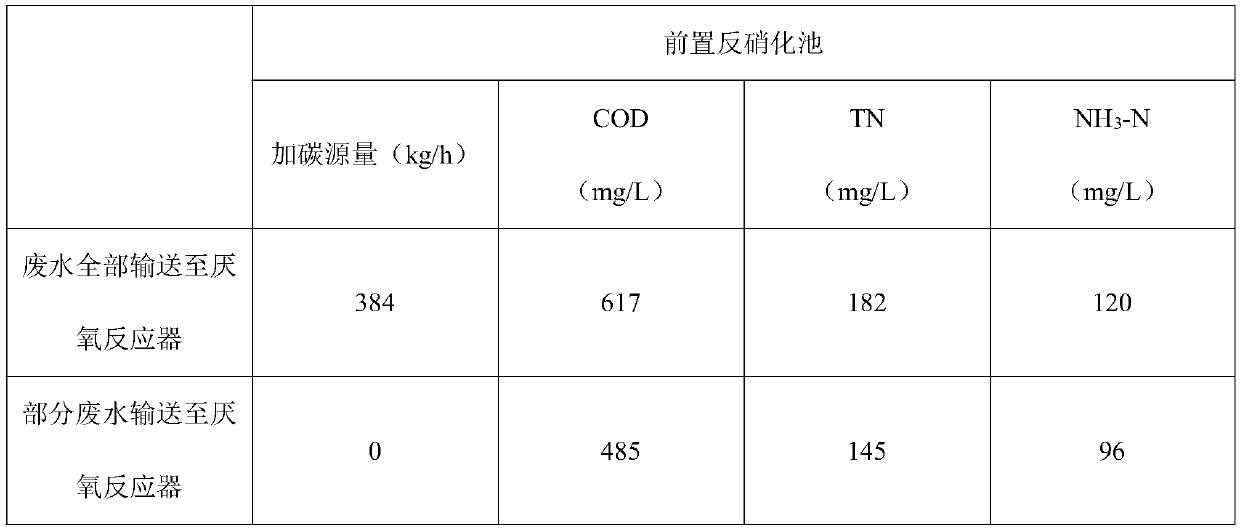

[0029] a. Adjust the pH of the high ammonia nitrogen wastewater to be treated to 5.5, and feed back the TN and COD values of the high ammonia nitrogen wastewater to be treated to 175m 3 / h of high ammonia nitrogen wastewater to be treated is transported to the anaerobic reactor, and then transported to the pre-denitrification tank of the pre-denitrification-aerobic-post-denitrification process after anaerobic treatment; and then the 65m 3 / h of high ammonia nitrogen wastewater to be treated is directly transported to the pre-denitrification tank, while controlling the DO value in the pre-denitrification tank to 0.2mg / L;

[0030] b. The waste water flows into the aerobic pool through the pre-denitrification pool. The DO value ...

Embodiment 12

[0039] The water inflow from the neomycin sulfate production process is 29m 3 / h, TN concentration is 620mg / L, NH 3 - High ammonia nitrogen wastewater with a N concentration of 430mg / L and a COD concentration of 8500mg / L shall be treated as follows:

[0040] a. Adjust the pH of the high ammonia nitrogen wastewater to be treated to 6.2, and feed back the TN and COD values of the high ammonia nitrogen wastewater to be treated to 20.5m 3 / h of high ammonia nitrogen wastewater to be treated is transported to the anaerobic reactor, and then transported to the pre-denitrification tank of the pre-denitrification-aerobic-post-denitrification process after anaerobic treatment; and then the 8.5m 3 / h of high ammonia nitrogen wastewater to be treated is directly transported to the pre-denitrification tank, while controlling the DO value in the pre-denitrification tank to 0.2mg / L;

[0041] b. The waste water flows into the aerobic pool through the pre-denitrification pool. The DO valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com