Rare earth modified slow-release ammonium sulfate fertilizer and preparation method thereof

A technology of rare earth modification and ammonium sulfate, which is applied in the direction of ammonium salt fertilizer, fertilizer mixture, nitrogen fertilizer, etc., can solve the problems of easy scaling and blockage of the system, secondary pollution, high energy consumption, etc., to improve crop quality, increase yield, and promote The effect of plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

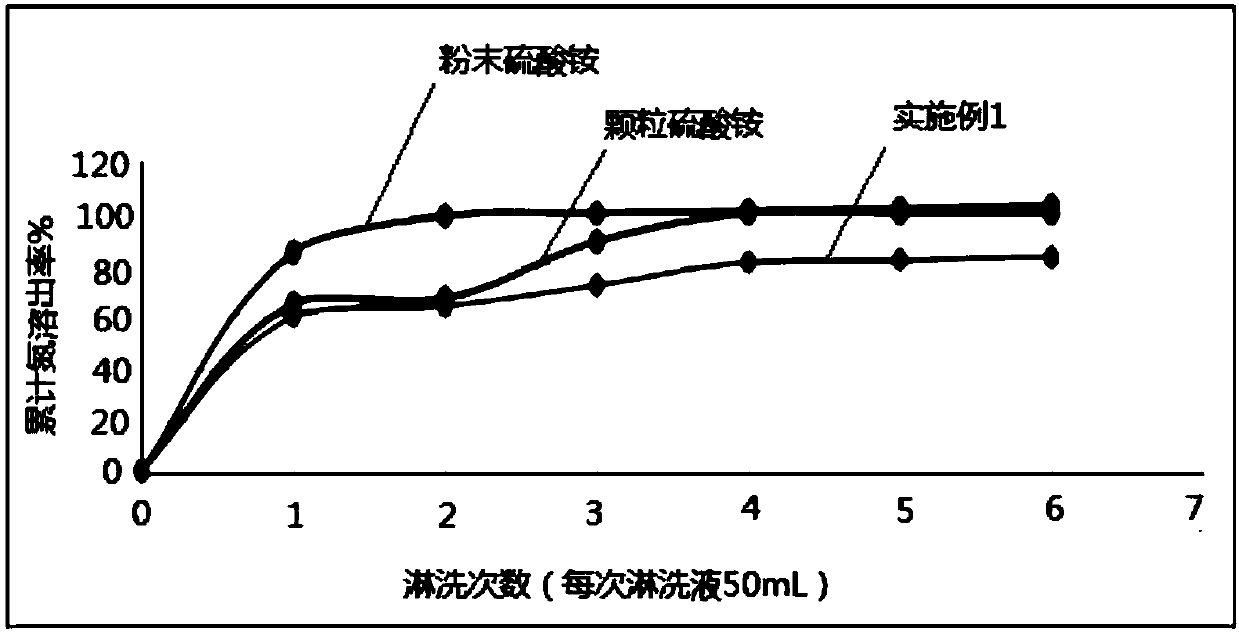

Examples

Embodiment 1

[0026] A rare earth modified slow-release ammonium sulfate fertilizer comprises the following components in parts by weight: 10 parts of rare earth modified hydrated aluminosilicate, 10 parts of pillared bentonite, and 80 parts of ammonium sulfate.

[0027] The preparation method of rare earth modified hydrated aluminosilicate hydrate: add sulfuric acid with a concentration of 5wt% to hydrated sodium aluminosilicate, the solid-liquid ratio of the two is 1:10, stir and mix evenly at 50°C to obtain a reaction solution; Add sodium chloride into the reaction solution, the concentration of sodium chloride in the reaction solution is 30wt%, stir and mix evenly at 50°C, then let it stand for layering, remove the solid reactant in the lower layer, adjust the pH to 6-7, and then mix the solid reactant with the rare earth according to the The mass ratio is 10:1, and microwave solid-phase synthesis is carried out in a tunnel microwave reactor. The microwave solid-phase synthesis adopts a ...

Embodiment 2

[0031] A rare earth modified slow-release ammonium sulfate fertilizer comprises the following components in parts by weight: 20 parts of rare earth modified hydrated aluminosilicate, 10 parts of pillared bentonite, and 70 parts of ammonium sulfate.

[0032] The preparation method of rare earth modified hydrated aluminosilicate hydrate: add sulfuric acid with a concentration of 5wt% to hydrated calcium aluminosilicate, the solid-liquid ratio of the two is 1:10, stir and mix evenly at 50°C to obtain a reaction solution; Add sodium chloride into the reaction solution, the concentration of sodium chloride in the reaction solution is 30wt%, stir and mix evenly at 50°C, then let it stand for layering, remove the solid reactant in the lower layer, adjust the pH to 6-7, and then mix the solid reactant with the rare earth according to the The mass ratio is 10:1, and microwave solid-phase synthesis is carried out in a tunnel microwave reactor. The microwave solid-phase synthesis adopts a...

Embodiment 3

[0036] A rare earth modified slow-release ammonium sulfate fertilizer comprises the following components in parts by weight: 5 parts of rare earth modified hydrated aluminosilicate, 10 parts of pillared bentonite, and 85 parts of ammonium sulfate.

[0037] The preparation method of rare earth modified hydrated aluminosilicate hydrate: add sulfuric acid with a concentration of 5wt% to hydrated magnesium aluminosilicate, the solid-liquid ratio of the two is 1:10, stir and mix evenly at 50°C to obtain a reaction solution; Add sodium chloride into the reaction solution, the concentration of sodium chloride in the reaction solution is 30wt%, stir and mix evenly at 50°C, then let it stand for layering, remove the solid reactant in the lower layer, adjust the pH to 6-7, and then mix the solid reactant with the rare earth according to the The mass ratio is 10:1, and microwave solid-phase synthesis is carried out in a tunnel microwave reactor. The microwave solid-phase synthesis adopts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com