Chain-extended hydroxyl terminated polybutadiene-polystyrene block copolymer/carbon nanotube conductive composite material and preparation method and application thereof

A technology of chain-extended hydroxyl-terminated polybutadiene and hydroxyl-terminated polybutadiene, which is applied in the field of conductive polymer composite materials and functional materials, and can solve problems such as difficult film formation, poor sensor response performance, and unstable electrical conductivity. , to achieve the effect of fast response, good stability and good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]

[0036] 1. Preparation of chain-extended hydroxyl polybutadiene macroinitiators

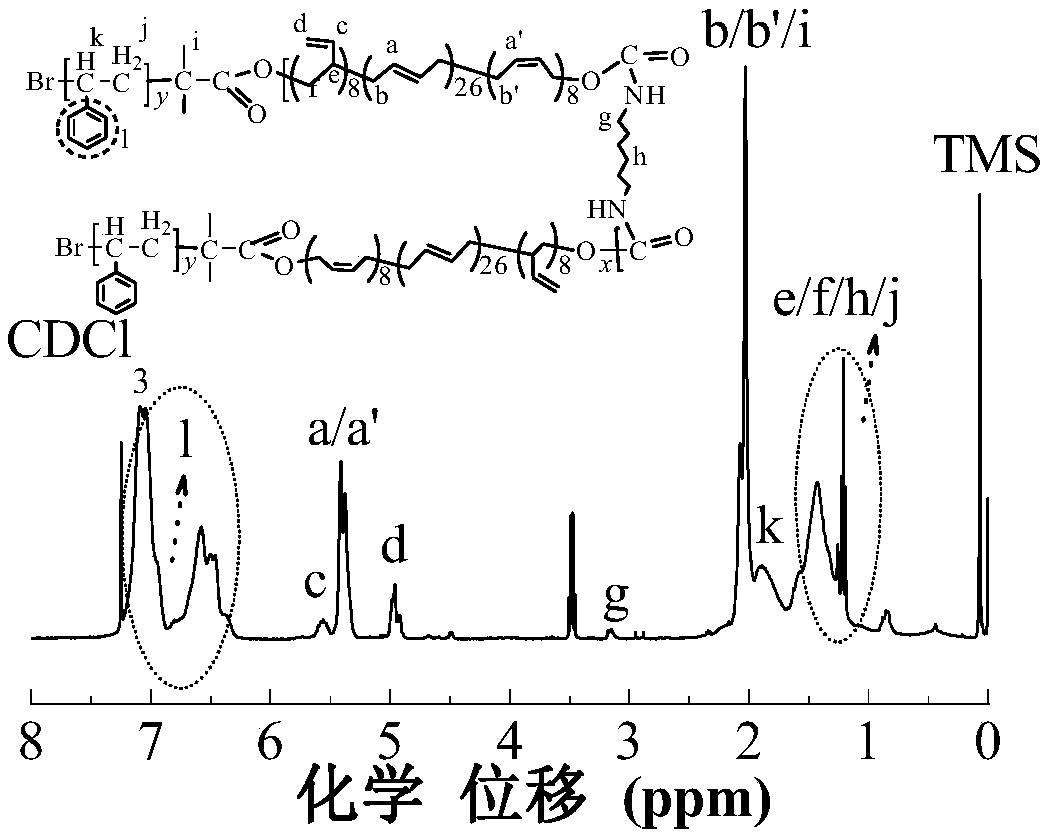

[0037] Dissolve 2 g (hydroxyl content 2.20 mmol) of hydroxyl-terminated polybutadiene (HTPB) represented by formula I in 12 mL of dry toluene and add it to a round bottom flask, then add 0.0925 g (0.55 mmol) hexamethylene diisocyanate (HDI, isocyanate group content 1.10mmol) and 12mg (0.019mmol) dibutyltin dilaurate (DBTDL), reacted at 60°C for 2 hours under a nitrogen atmosphere, and dried the product under vacuum at 40°C for 12 hours to obtain formula II- The chain-extended hydroxyl-terminated polybutadiene (HTPB) shown in 1 5 , molecular weight is 11880).

[0038] Dissolve 23.76g (2mmol) of chain-extended hydroxyl-terminated polybutadiene and 0.5252g (5.2mmol) of triethylamine (TEA) in 30mL of dry toluene and add them to a round-bottomed flask, cool to 0°C, and Add 1.195 g (5.2 mmol) of dibromoisobutyryl bromide (BIB) dissolved in 10 mL of dry toluene dropwise, stir in an ice bath...

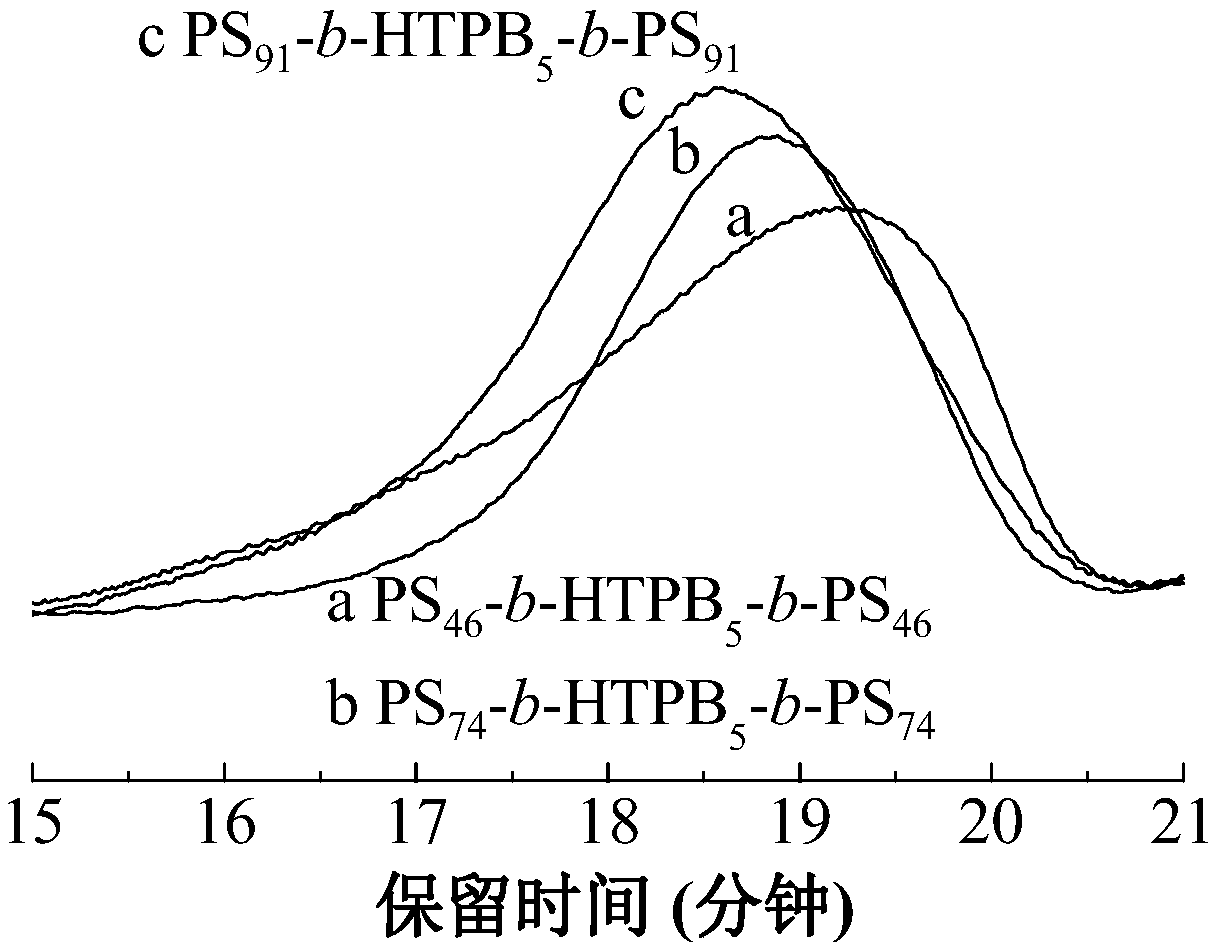

Embodiment 2

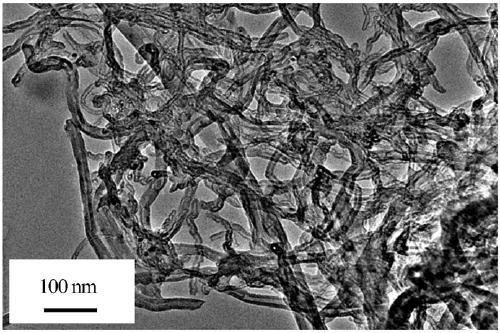

[0043] In step 2 of this embodiment, the amount of multi-walled carbon nanotubes is 0.2376g, and other steps are the same as in embodiment 1 to obtain a chain-extended hydroxyl polybutadiene-polystyrene block copolymer / carbon nanotube conductive composite Materials (MWCNTs@PS 74 -b-HTPB 5 -b-PS 74 ).

Embodiment 3

[0045] In step 2 of this embodiment, the amount of multi-walled carbon nanotubes is 0.6449g, and other steps are the same as in embodiment 1 to obtain a chain-extended hydroxyl polybutadiene-polystyrene block copolymer / carbon nanotube conductive composite Materials (MWCNTs@PS 74 -b-HTPB 5 -b-PS 74 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com