PVC stone plastic floor and preparation method thereof

A technology of stone-plastic flooring and PVC resin powder, which is applied in the direction of construction, building structure, floor, etc., can solve the problems of affecting the quality of PVC stone-plastic flooring, unsatisfied mechanical properties, and low mechanical properties of stone-plastic flooring. Achieve excellent sound insulation effect, enhance chemical corrosion resistance, and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

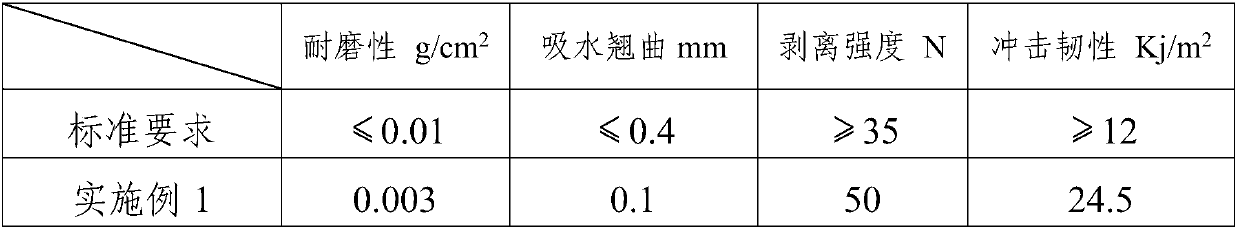

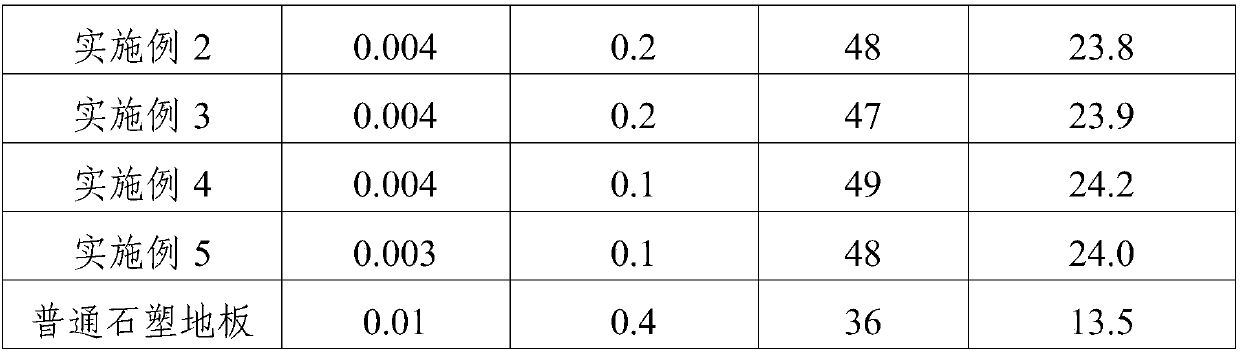

Examples

Embodiment 1

[0021] A PVC stone-plastic floor, comprising the following raw materials in parts by weight: 200 parts of PVC resin powder, 700 parts of calcium filler, 30 parts of glass fiber, 1.2 parts of propylenediamine phosphate, 5 parts of methyl cellulose, alkylphenol 10 parts of polyoxyethylene ether, 12 parts of organotin stabilizer, 12 parts of adipic acid, 7 parts of silicone compounds.

[0022] The preparation method of the above-mentioned PVC stone-plastic floor comprises the following preparation steps:

[0023] (1) Mix PVC resin powder, calcium filler, glass fiber, and propylenediamine phosphate into a stirring reactor, and stir for 2 hours at a speed of 1200r / min and a temperature of 180°C. After the stirring is completed, add methyl Cellulose, alkylphenol polyoxyethylene ether, organotin stabilizer, adipic acid, and silicone compounds are put into the stirring reactor together, adjust the rotation speed to 500r / min, stir at 120°C for 85min, and wait until the stirring is comp...

Embodiment 2

[0027] A PVC stone-plastic floor, comprising the following raw materials in parts by weight: 250 parts of PVC resin powder, 400 parts of calcium filler, 25 parts of glass fiber, 1 part of xylene, 7 parts of sodium acrylate, sodium naphthalenesulfonate formaldehyde condensate 6 parts of salt, 11 parts of organotin stabilizer, 15 parts of adipic acid, and 6 parts of silicone compounds.

[0028] The preparation method of the above-mentioned PVC stone-plastic floor comprises the following preparation steps:

[0029] (1) Mix PVC resin powder, calcium filler, glass fiber, and xylene into a stirring reactor, and stir for 2 hours at a speed of 1100r / min and a temperature of 140°C. After stirring, add sodium acrylate, naphthalene Sodium salt of sulfonic acid formaldehyde condensate, organotin stabilizer, adipic acid, and silicone compounds are put into the stirring reactor together, adjust the rotation speed to 450r / min, and stir at 110°C for 80min. After the stirring is completed, coo...

Embodiment 3

[0033] A PVC stone-plastic floor, comprising the following raw materials in parts by weight: 300 parts of PVC resin powder, 500 parts of calcium filler, 20 parts of glass fiber, 1.8 parts of sodium fluorosilicate, 6 parts of hydroxymethyl cellulose, alkyl 5 parts of phenol polyoxyethylene ether, 15 parts of organotin stabilizer, 5 parts of adipic acid, and 8 parts of silicone compounds.

[0034] The preparation method of the above-mentioned PVC stone-plastic floor comprises the following preparation steps:

[0035] (1) Mix PVC resin powder, calcium filler, glass fiber, and sodium fluorosilicate into a stirring reactor, and stir for 1 hour at a speed of 1000r / min and a temperature of 100°C. After the stirring is completed, add methylol Base cellulose, alkylphenol polyoxyethylene ether, organotin stabilizer, adipic acid, and silicone compounds are put into the stirring reactor together, adjust the rotation speed to 400r / min, stir at 90°C for 70min, and wait for stirring After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com