Preparation and application of carbon quantum dot fluorescent probe

A technology of fluorescent probes and carbon quantum dots, applied in fluorescence/phosphorescence, nano optics, luminescent materials, etc., can solve the problems of low yield of fluorescent carbon quantum dots, poor recognition response sensitivity and anti-interference ability, complex reaction conditions, etc. , to achieve excellent fluorescence properties, good optical performance and stability, simple and safe method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 2 g of anhydrous citric acid into a 50 mL round bottom flask, then add 1 g of ethylenediamine, and heat the mixture at 180° C. for 30 minutes under normal pressure. After cooling, 100 ml of deionized water was added to dissolve the resulting mixture. The above solution was dialyzed with a dialysis bag (MWCO=1000) for 48 hours. After dialysis, the solution was freeze-dried to obtain 0.96 g carbon quantum dot fluorescent probes (N-CDs), which were dissolved in deionized water for further use.

Embodiment 2

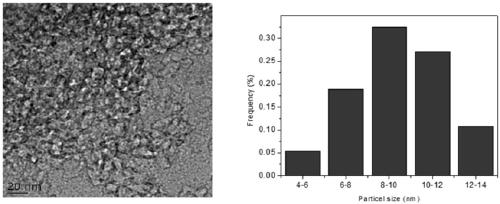

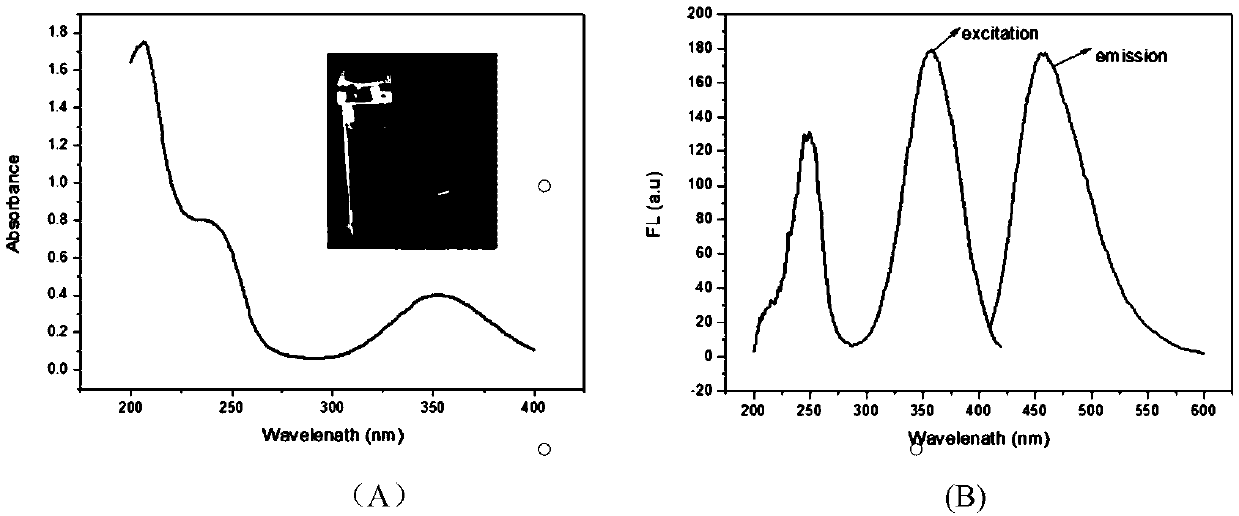

[0032] The carbon quantum dot fluorescent probe gained in Example 1 is formulated into an aqueous solution of 0.001g / L, dripped on a copper grid with a carbon film, and tested after vacuum drying, and the particle size distribution of the carbon quantum dot aqueous solution is recorded to be uniform, and The diameter is concentrated at 8-10nm (the particle diameter of more than 40% carbon quantum dot fluorescent probes is at 8-10nm), such as figure 1 shown. And measure its ultraviolet and fluorescence excitation and emission spectra, such as figure 2 As shown, the maximum fluorescence excitation peak and emission peak of the carbon quantum dots are 350nm and 458nm respectively, showing strong blue fluorescence, and the quantum yield is 20.6%.

Embodiment 3

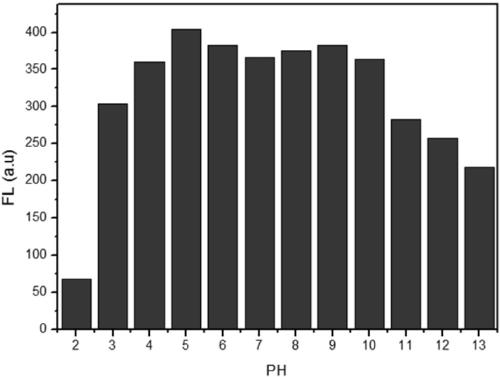

[0034] In this example, the effect of pH on the fluorescence intensity of the carbon quantum dot fluorescent probe was studied. The carbon quantum dot fluorescent probe obtained in Example 1 was formulated into a 0.001 g / L aqueous solution and adjusted with NaOH / HCl aqueous solution to prepare carbon quantum dot solutions with different pHs. Such as image 3 As shown, in solutions with higher or lower pH values, the luminescence intensity decreases, but the luminescence intensity is still greater in weak acid and weak base (4≤pH≤11) solutions. This pH-dependent fluorescence is caused by the protonation and de-excitation of carboxyl or amino groups on the surface of N-CDs, which leads to the electrostatic doping or charging of carbon quantum dot fluorescent probes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com