Arsenic removal method for arsenic-fixing copper-containing slag

A copper slag and arsenic removal technology, which is applied in the field of metallurgy, can solve the problems of arsenic-fixed copper slag cleaning, high-efficiency arsenic removal, etc., and achieve shortened arsenic extraction technology, broad market application prospects, high economic benefits and environmental protection benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

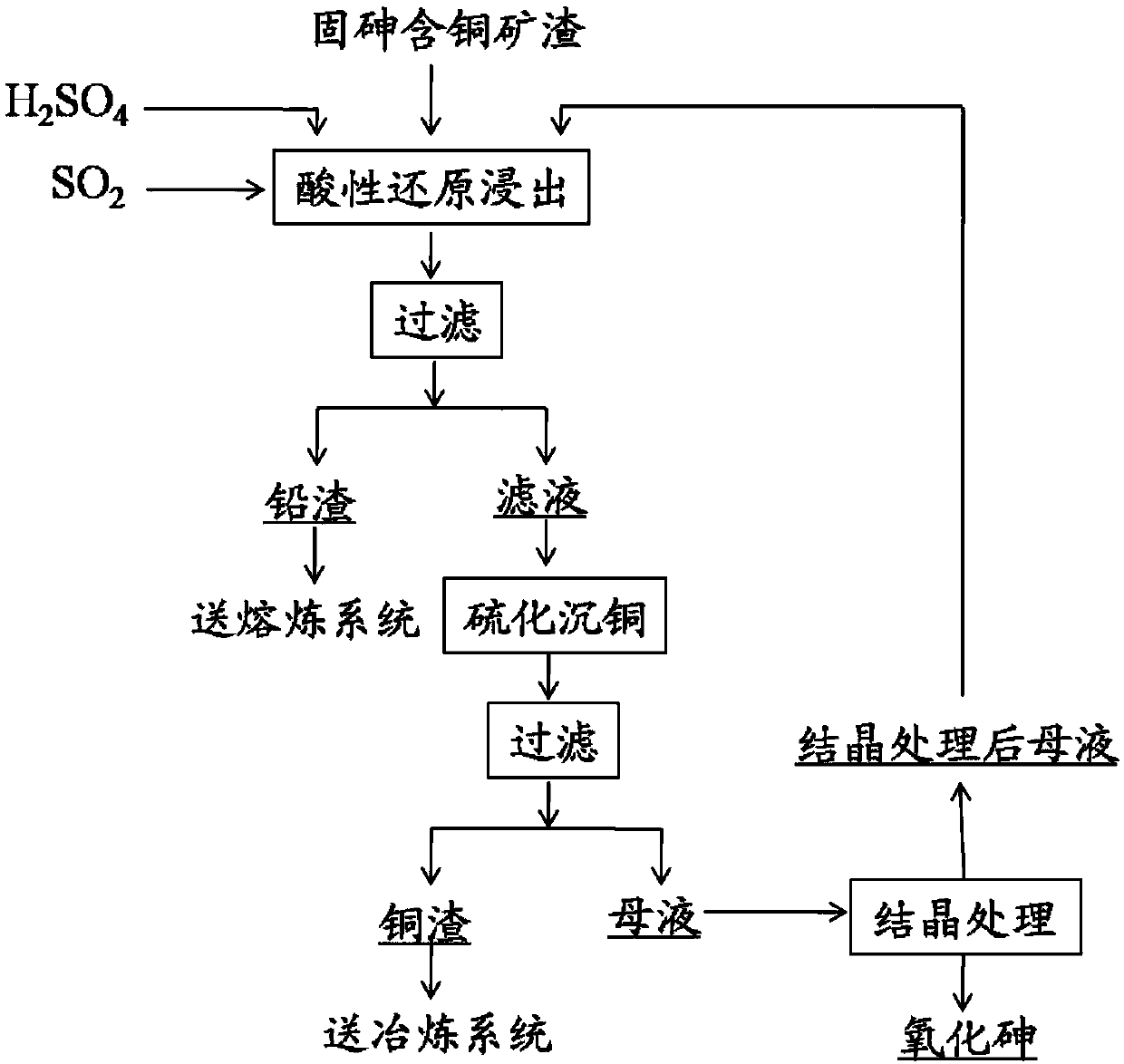

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 100g of arsenic-fixed copper-containing slag (dry basis), which contains As10.56%, Cu9.14%, Fe7.73%, Pb15.0%, and leaching solution 500g (containing arsenic 12.7g / L), with Concentrated sulfuric acid is used to adjust the acidity to 150g / L. Mix the arsenic-fixed copper-containing slag with the leaching solution into a 2L beaker;

[0031] (2) Start the electric stirring, and connect the air duct, and continuously inject SO 2 Gas, heated to 80°C, maintained at a constant temperature for 1.5 hours, then filtered while hot to obtain lead slag and filtrate;

[0032] (3) Lead slag is sent to lead smelting system, feeds hydrogen sulfide gas in filtrate, every 30min detects the copper content in the filtrate, stops aeration when copper content<0.02g / L in the filtrate, carries out filtration again, obtains Copper slag and mother liquor;

[0033] (4) Send the copper slag to the copper smelting system. After the mother liquor is crystallized, arsenic oxide is precipitat...

Embodiment 2

[0036] (1) Take 100g of arsenic-fixed copper-containing slag (dry basis), which contains As10.56%, Cu9.14%, Fe7.73%, Pb15.0%, and 600g of leachate (containing arsenic 12.7g / L). Concentrated sulfuric acid is used to adjust the acidity to 160g / L. Mix the arsenic-fixed copper-containing slag with the leaching solution into a 2L beaker;

[0037] (2) Start the electric stirring, and connect the air duct, and continuously inject SO 2 Gas, heated to 85°C, maintained at a constant temperature for 1.6 hours, then filtered while hot to obtain lead slag and filtrate;

[0038] (3) Lead slag is sent to lead smelting system, feeds hydrogen sulfide gas in filtrate, every 30min detects the copper content in the filtrate, stops aeration when copper content<0.02g / L in the filtrate, carries out filtration again, obtains Copper slag and mother liquor;

[0039] (4) Send the copper slag to the copper smelting system. After the mother liquor is crystallized, arsenic oxide is precipitated. After c...

Embodiment 3

[0042] (1) Take 100g of arsenic-fixed copper-containing slag (dry basis), which contains As10.56%, Cu9.14%, Fe7.73%, and Pb15.0%, and 800g of leaching solution (containing arsenic 12.7g / L). Concentrated sulfuric acid is used to adjust the acidity to 160g / L. Mix the arsenic-fixed copper-containing slag with the leaching solution into a 2L beaker;

[0043] (2) Start the electric stirring, and connect the air duct, and continuously inject SO 2 Gas, heated to 90°C, maintained at a constant temperature for 1.5 hours, then filtered while hot to obtain lead slag and filtrate;

[0044] (3) Lead slag is sent to lead smelting system, feeds hydrogen sulfide gas in filtrate, detects the copper content in filtrate once every 30min, stops aerating when copper content<0.02g / L in filtrate and carries out filtration treatment again, obtains Copper slag and mother liquor;

[0045] (4) The copper slag is sent to the copper smelting system, the mother liquor is crystallized to precipitate arse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com