A processing method and equipment for high-efficiency, high-resolution nano-patterns

A nano-pattern and processing method technology, applied in the field of nano-processing, can solve the problems of low depth and width of nano-pattern processing, poor image quality, etc., and achieve the effect of enhanced etching ability, high resolution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following describes the embodiments of the present invention in detail, and those skilled in the art will understand that the following embodiments are intended to explain the present invention, and should not be regarded as limiting the present invention. Unless otherwise specified, if the specific techniques or conditions are not clearly described in the following examples, those skilled in the art can carry out according to the commonly used techniques or conditions in this field or according to the product instructions. The reagents or instruments used were not indicated by the manufacturer, and they were all conventional products available in the market.

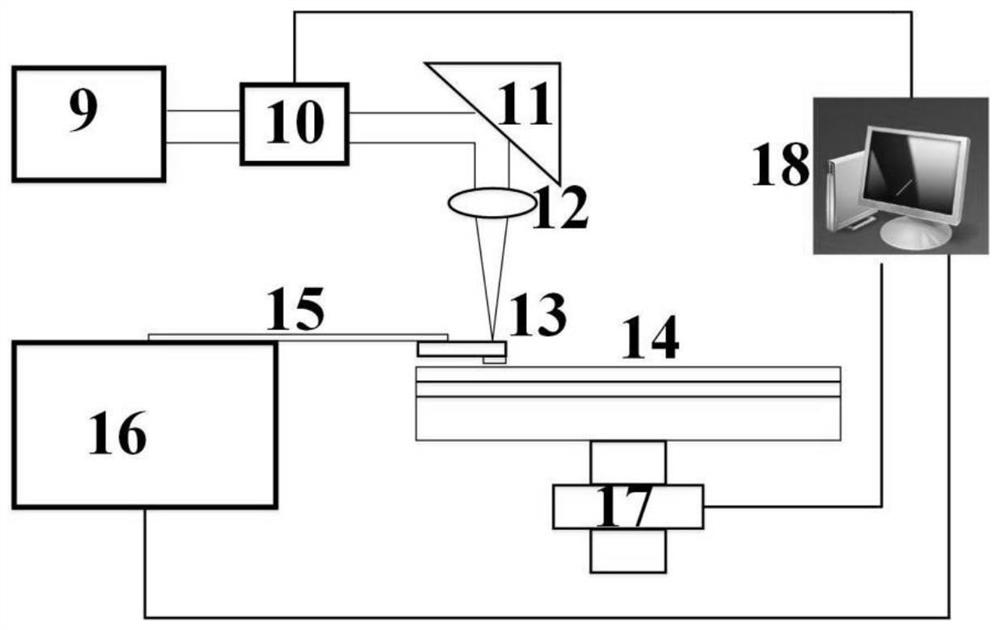

[0045] A processing method for high-efficiency and high-resolution nano-patterns of the present invention, specifically comprising the following steps:

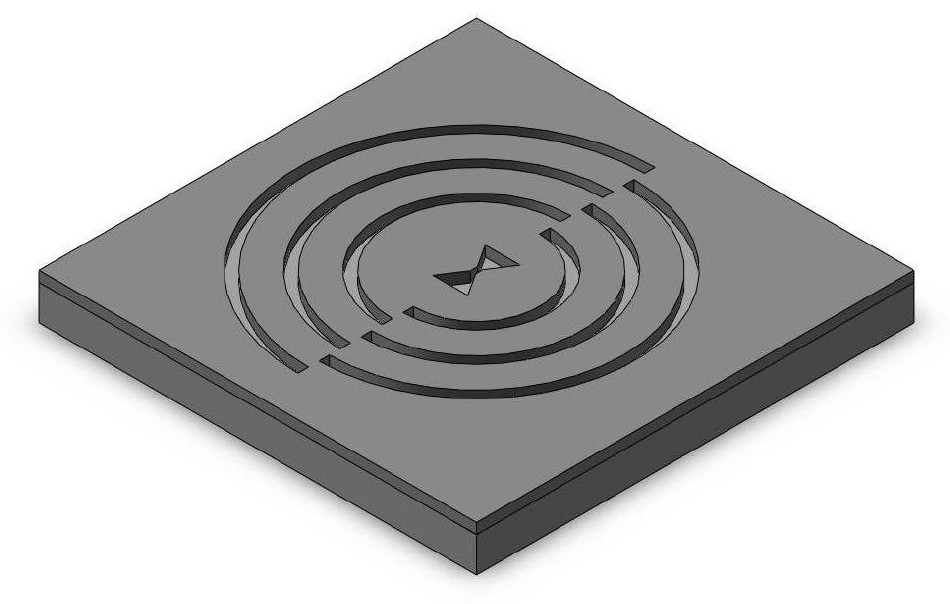

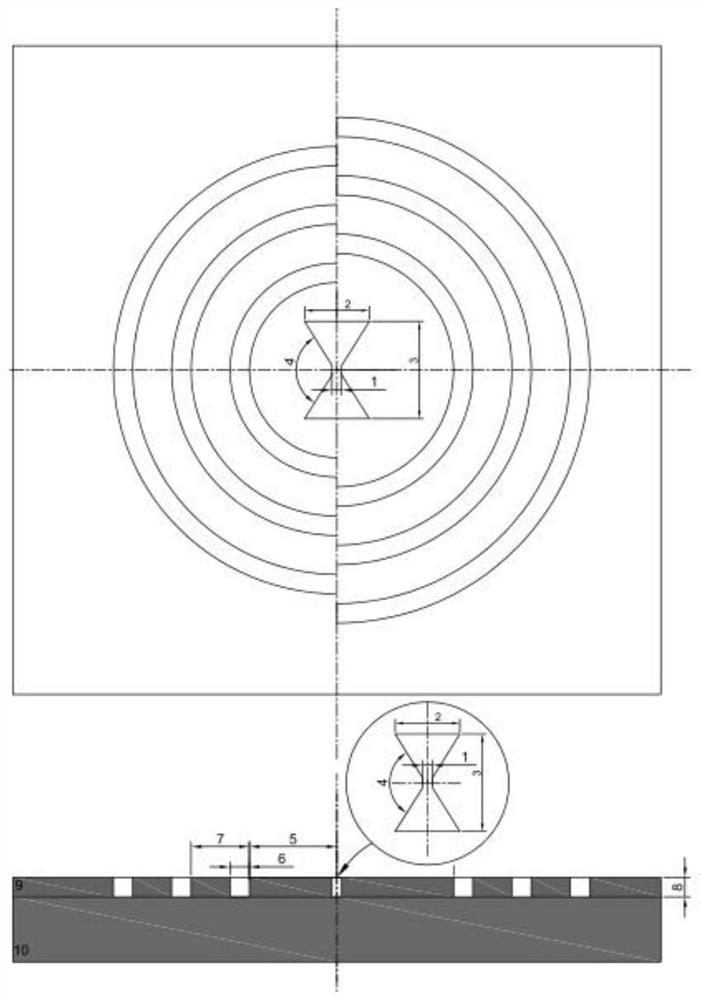

[0046] (1) First prepare a surface plasmon lens with an alternating composite structure of bowknot and concentric semicircular grooves. The surface plasmon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com