A multi-stage reforming power generation system using liquid fuel as hydrogen source for fuel cells

A fuel cell and power generation system technology, which is applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of easy poisoning and decay of catalysts, clogging of reaction pipelines, complex composition, etc., to reduce difficulty and achieve dynamic Coupling, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the invention are clearly and completely described in conjunction with the accompanying drawings in the present invention. The specific examples described here are only used to explain the present invention, not to limit the present invention.

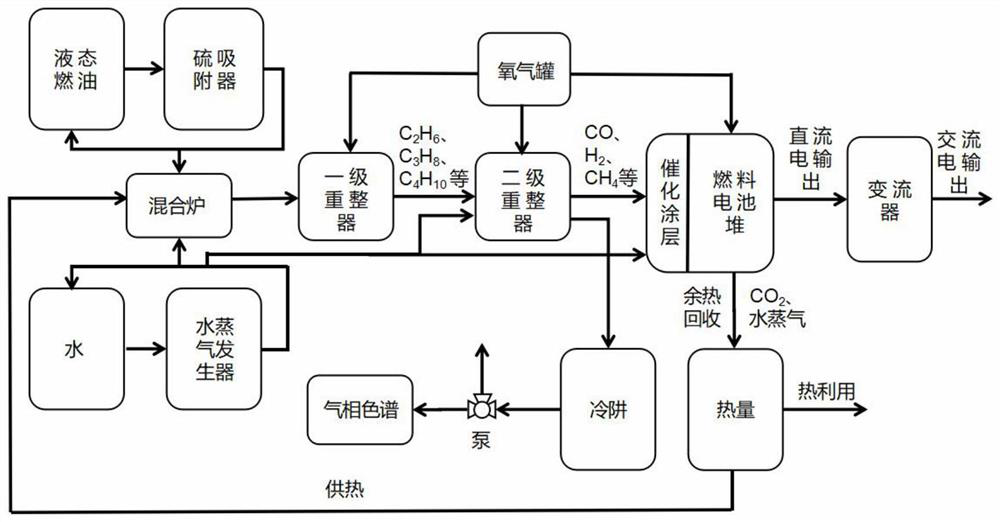

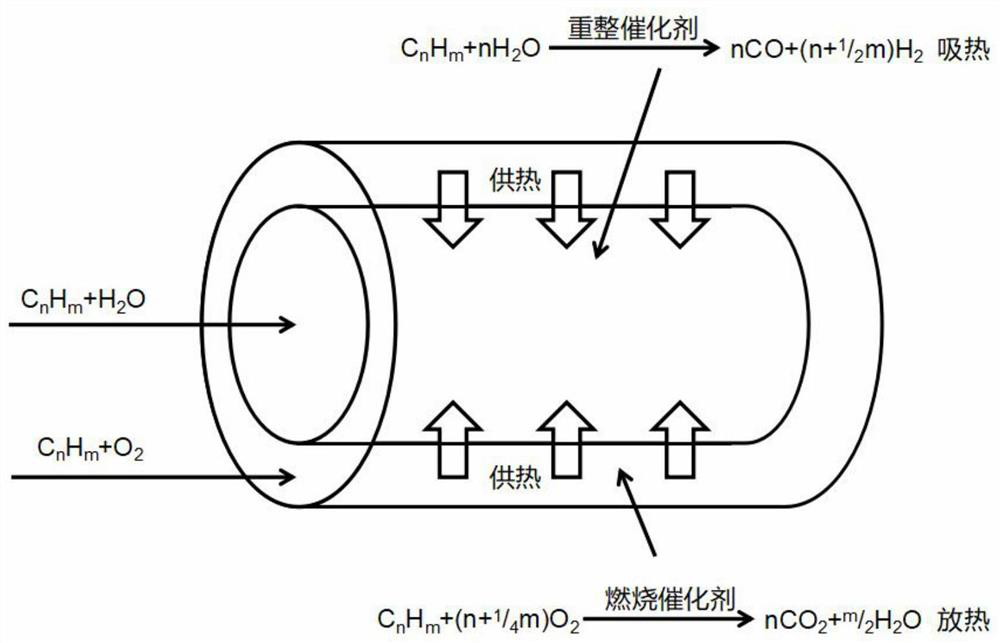

[0023] figure 1It is a schematic structural diagram of a multi-stage reforming system in which liquid kerosene is used as a hydrogen source for a fuel cell. Equipped with liquid fuel oil (gasoline is mainly composed of C5-C12 aliphatic hydrocarbons and cycloalkanes, and its distillation range is 30-220°C; kerosene is mainly composed of C11-C17 saturated hydrocarbons, unsaturated hydrocarbons and aromatic hydrocarbons, Its boiling range is 180-310°C; while diesel oil is a light petroleum product, mainly a complex hydrocarbon mixture of C10-C22, and its boiling range is 180-370°C) the storage tank is conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com