Electrolyte for aluminum negative electrode energy storage device, aluminum negative electrode energy storage device and preparation method thereof

An electrolyte and negative electrode technology, which is applied in the field of electrochemical energy storage devices, can solve the problems of poor matching of Al negative electrode system, poor battery cycle performance, and poor low-temperature performance, so as to improve low-temperature charge and discharge performance and discharge performance. , low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

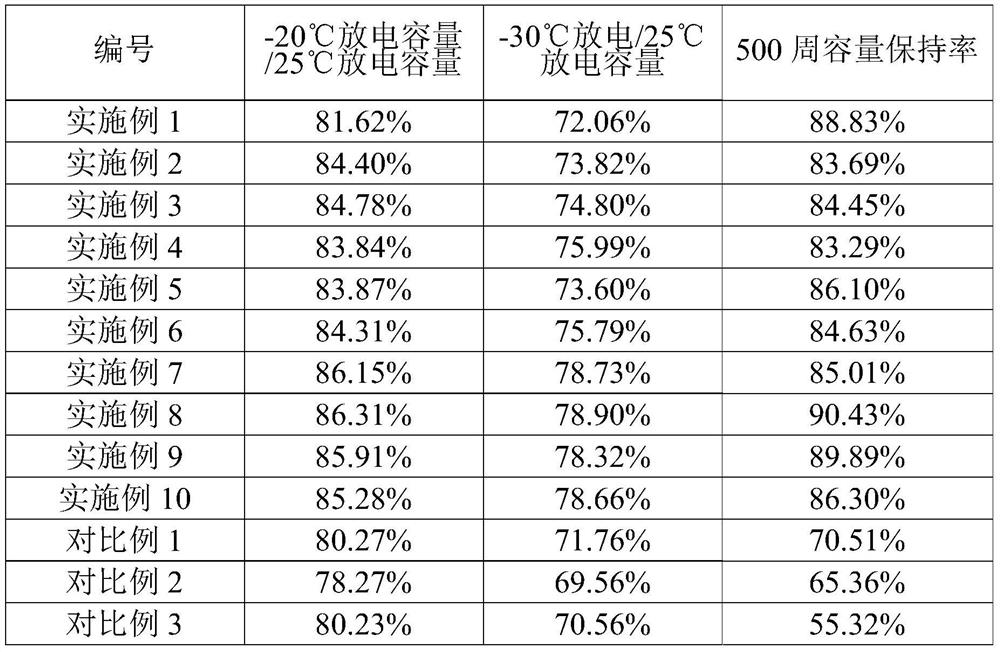

Examples

preparation example Construction

[0052] According to a second aspect of the present invention, there is provided a method for preparing an electrolyte for an aluminum negative electrode energy storage device, comprising the following steps:

[0053] The lithium salt, the organic solvent and the additive are uniformly mixed to obtain an electrolyte solution for an aluminum negative electrode energy storage device.

[0054] The preparation method of the electrolytic solution of the aluminum negative electrode energy storage device of the present invention is simple, convenient to operate, and can be mass-produced.

[0055] In one embodiment, a method for preparing an electrolyte for an aluminum negative energy storage device comprises the following steps:

[0056] Mix the cyclic ester solvent and the linear ester solvent in proportion, add additives and mix to obtain a solvent; then add lithium molecular sieves to dry, then add lithium salt at a temperature of 0-15°C to obtain an aluminum negative electrode ene...

Embodiment 1

[0089] A low-temperature electrolyte comprising: Lithium salt LiPF 6 , organic solvents include 10vol% fluoroethylene carbonate (FEC), 10vol% propylene carbonate (PC), 40vol% diethyl carbonate (DEC) and 40vol% ethyl methyl carbonate (EMC) (based on organic Solvent, and be 100%), additive is vinylene carbonate (VC) and fluoroethylene carbonate (FEC), the molar concentration of lithium salt in organic solvent is 1mol / L, fluoroethylene carbonate (FEC) in The mass percent content of the lithium salt and the organic solvent is 5%, and the mass percent content of vinylene carbonate (VC) in the lithium salt and the organic solvent is 5%.

[0090] The preparation method of low-temperature electrolyte comprises the following steps:

[0091] FEC, PC, DEC and EMC are mixed in proportion, each independently adding 5% (accounting for the mass ratio of lithium salt and organic solvent) of FEC and VC as additives, after mixing to obtain the electrolyte solvent, add 10% (mass ratio than) Li...

Embodiment 2

[0093] A low-temperature electrolyte comprising: Lithium salt LiPF 6 , organic solvents include 10vol% ethylene carbonate (EC), 40vol% ethyl methyl carbonate (EMC), 10vol% dimethyl carbonate (DMC), 10vol% diethyl carbonate (DEC) and 30vol% Ethyl propionate (EP) (benchmark is organic solvent, sum is 100%), additive is vinylene carbonate (VC) and fluoroethylene carbonate (FEC), the molar concentration of lithium salt in organic solvent is 1mol / L, the mass percentage of fluoroethylene carbonate (FEC) in lithium salt and organic solvent is 5%, and the mass percentage of vinylene carbonate (VC) in lithium salt and organic solvent is 5%.

[0094] The preparation method of low-temperature electrolyte comprises the following steps:

[0095] EC, EMC, DMC, DEC and EP are mixed in proportion, each independently adding 5% (accounting for the mass ratio of lithium salt and organic solvent) of FEC and VC as additives and mixing to obtain electrolyte solvent, adding 10% ( (mass ratio) lit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com