Silicon carbon negative electrode material and its preparation method, application and prepared lithium ion battery

A negative electrode material, silicon carbon technology, applied in the field of silicon carbon negative electrode material and its preparation, can solve the problems of low low temperature discharge performance, low lithium intercalation rate performance, complicated preparation steps, etc., and achieves improved low temperature charge and discharge performance, low cost, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

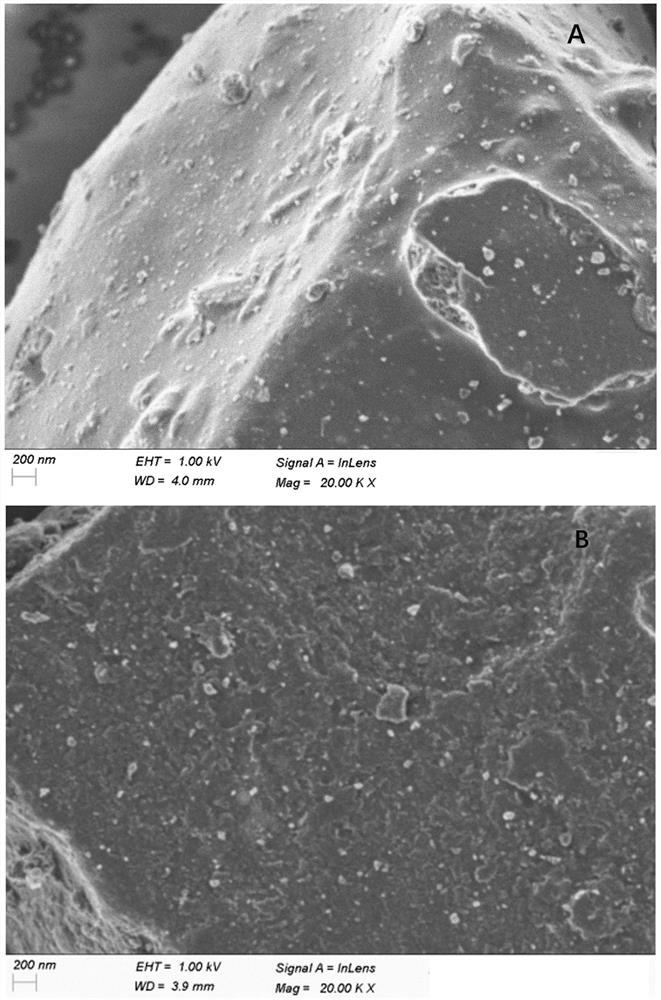

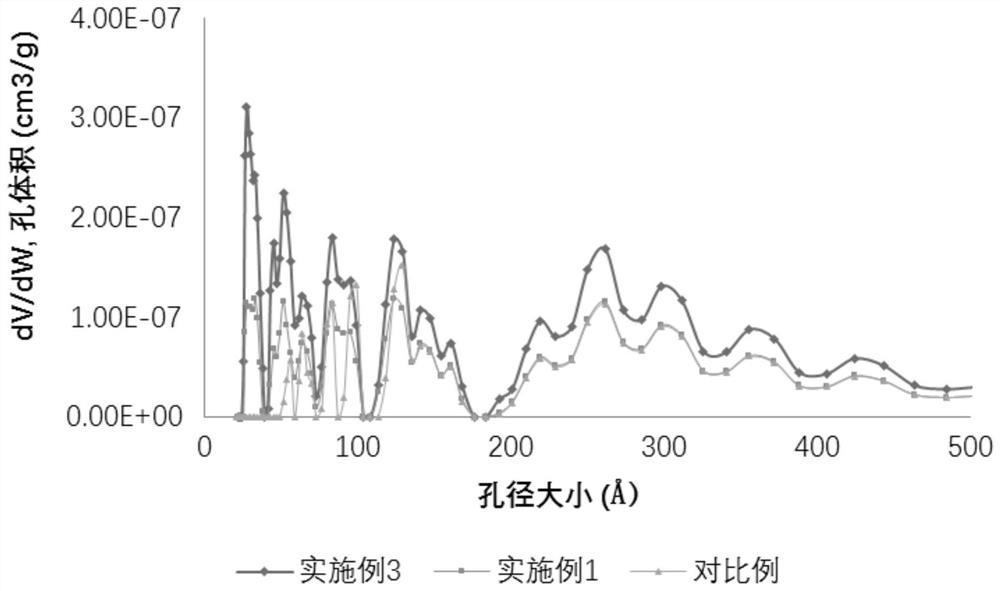

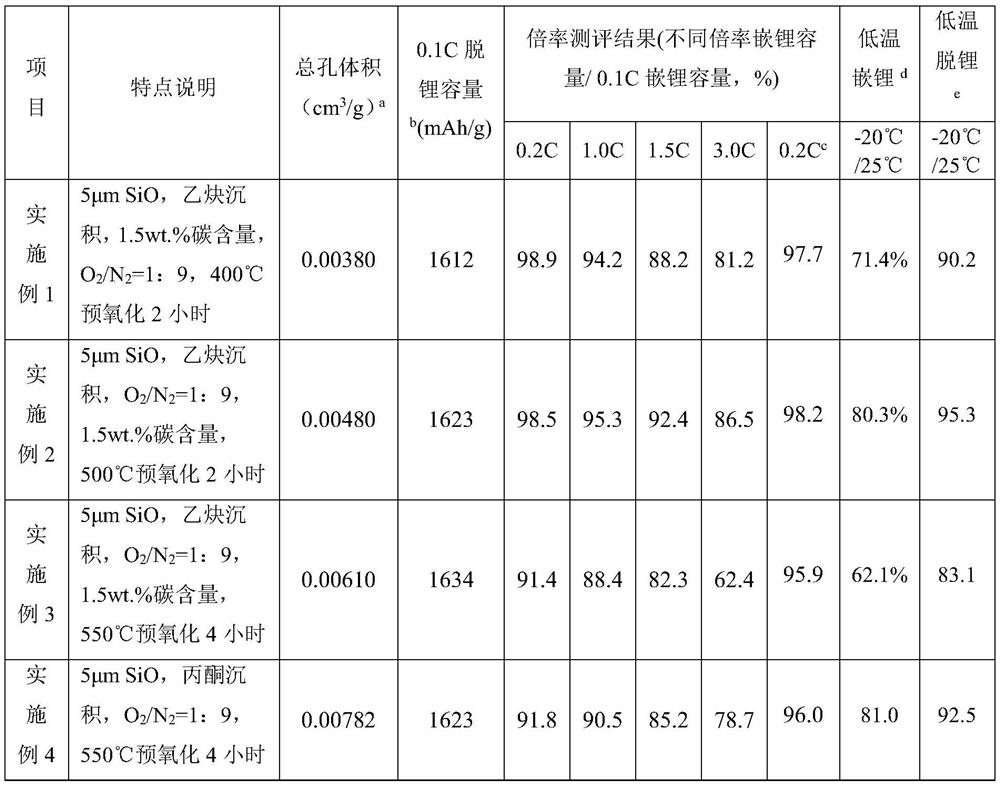

[0051] Silicon oxide (purity>99.9%, said % is mass percent, Beijing Shengbo Gaotai Optical Technology Co., Ltd.) material with a median particle size of 5 μm was selected, and acetylene (Suzhou Jinhong) was used as the coating carbon source. Firstly, silicon oxide was heated to 1000°C under nitrogen condition at 5°C / min and then stabilized for 3 hours; the silicon oxide raw material after the above treatment was put into a horizontal heating reactor, and the nitrogen flow rate was kept at 50 sccm, and the nitrogen flow rate was 5°C / min. Min is heated to 800°C, and then the carbon source gas is introduced (the volume concentration of the carbon source gas acetylene in the total gas is 5%, and the introduction time is designed according to the carbon content of the final sample obtained as 1.5wt.%). After the end, switch to pure Nitrogen (50sccm) and lower the temperature to 400°C; flow a mixed gas of oxygen:nitrogen=1:9 (volume ratio) for 2 hours, switch to nitrogen (100sccm) af...

Embodiment 2

[0053] Silicon oxide (purity>99.9%, said % is mass percent, Beijing Shengbo Gaotai Optical Technology Co., Ltd.) material with a median particle size of 5 μm was selected, and acetylene (Suzhou Jinhong) was used as the coating carbon source. Firstly, silicon oxide was heated to 1000°C under nitrogen condition at 5°C / min and then stabilized for 3 hours; the silicon oxide raw material after the above treatment was put into a horizontal heating reactor, and the nitrogen flow rate was kept at 50 sccm, and the nitrogen flow rate was 5°C / min. Min is heated to 800°C, and then the carbon source gas is introduced (the volume concentration of the carbon source gas acetylene in the total gas is 5%, and the introduction time is designed according to the carbon content of the final sample obtained as 1.5wt.%); after the end, switch to pure Nitrogen (50sccm) and lower the temperature to 500°C, pass through a mixed gas of oxygen / nitrogen = 1:9 (volume ratio) for 2 hours, switch to nitrogen (1...

Embodiment 3

[0055] Silicon oxide (purity>99.9%, said % is mass percent, Beijing Shengbo Gaotai Optical Technology Co., Ltd.) material with a median particle size of 5 μm was selected, and acetylene (Suzhou Jinhong) was used as the coating carbon source. Firstly, silicon oxide was heated to 1000°C under nitrogen condition at 5°C / min and then stabilized for 3 hours; the silicon oxide raw material after the above treatment was put into a horizontal heating reactor, and the nitrogen flow rate was kept at 50 sccm, and the nitrogen flow rate was 5°C / min. Min is heated to 800°C, and then the carbon source gas is introduced (the volume concentration of the carbon source gas acetylene in the total gas is 5%, and the introduction time is designed according to the carbon content of the final sample obtained as 1.5wt.%); after the end, switch to pure Nitrogen (50sccm) and lower the temperature to 550°C, pass through a mixed gas of oxygen / nitrogen = 1:9 (volume ratio) for 4 hours, switch to nitrogen (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com