A kind of negative electrode binder and its application

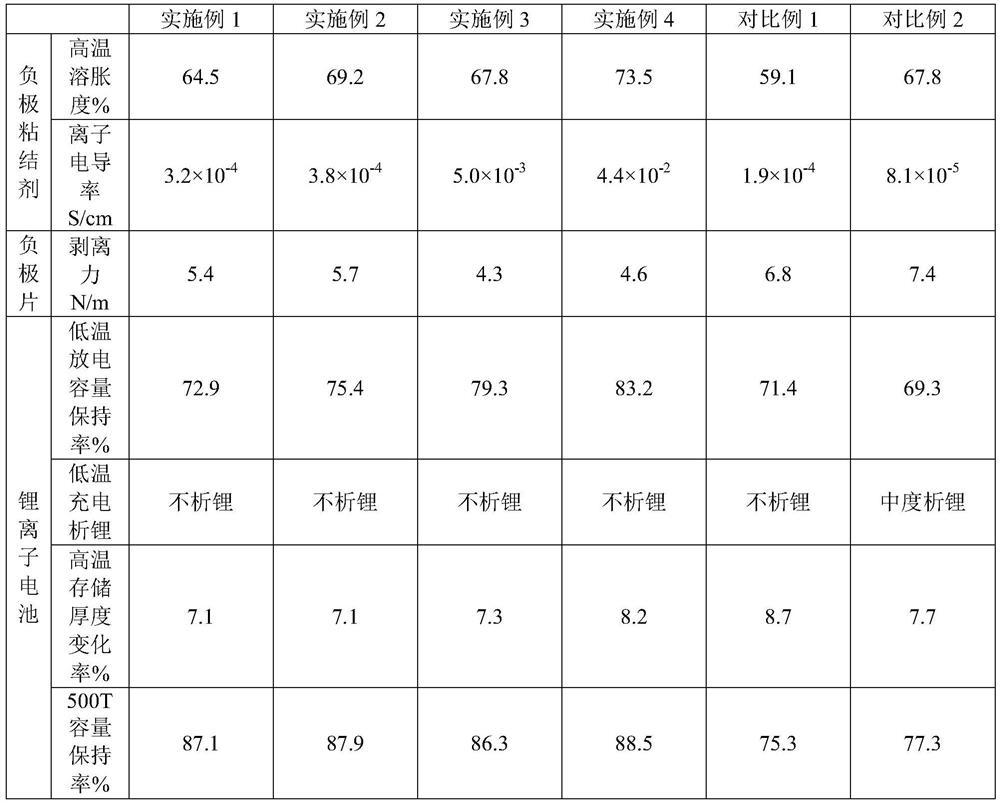

A technology of a binder and a negative electrode, applied in the negative electrode binder and its application field, can solve the problem of no obvious improvement in electrical properties, and achieve the improvement of high temperature storage performance and high temperature stability performance, adhesion performance and anti-expansion performance improvement. , the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

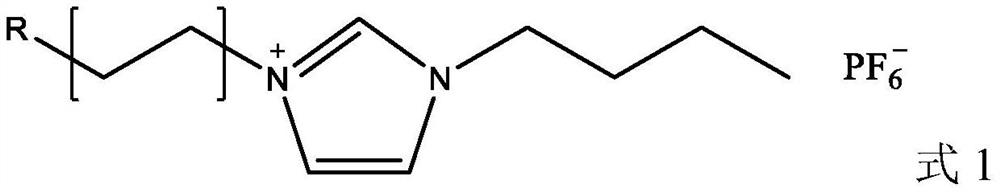

[0052] The preparation method of the aforesaid negative electrode binder of the present invention comprises: heating the system containing unsaturated monomer, 1-vinyl-3-butylimidazole hexafluorophosphate, initiator and surfactant to carry out polymerization reaction, polymerization reaction After the completion, adjust the pH of the reaction system to 6-8 to obtain the negative electrode binder.

[0053] The specific process parameters of the above preparation method and the selection of reactants can be the same as those mentioned above, and will not be repeated here.

[0054] The second aspect of the present invention is to provide a negative electrode sheet, which includes the negative electrode binder of the aforementioned first aspect.

[0055] The negative electrode sheet includes a negative electrode current collector and a negative electrode material coated on the surface of the current collector.

[0056] Specifically, during operation, disperse the negative electro...

Embodiment 1

[0067] The preparation method of the negative electrode binder of the present embodiment comprises:

[0068] 1. Put the materials participating in the polymerization reaction into a reaction vessel equipped with a stirrer, a thermometer and a condenser to carry out the polymerization reaction;

[0069] Wherein, the material that participates in polymerization reaction is:

[0070] Methacrylic acid (monomer containing acidic functional group) 89.5 parts by mass

[0071] 5.5 parts by mass of methacrylamide (unsaturated amide)

[0072] 1.5 parts by mass of 2,2,2-trifluoroethyl methacrylate (unsaturated fluorinated carboxylic acid alkyl ester)

[0073] 1.5 parts of 1-vinyl-3-butylimidazolium hexafluorophosphate

[0074] Sodium dodecylphenyl ether sulfonate (surfactant) 1.5 parts by mass

[0075] Potassium persulfate (initiator) 0.5 parts by mass

[0076] 150 parts by mass of deionized water;

[0077] 2. After fully stirring, heat to 75°C to initiate polymerization, stop the ...

Embodiment 2

[0079] The preparation method of the negative electrode binder of the present embodiment comprises:

[0080] 1. Put the materials participating in the polymerization reaction into a reaction vessel equipped with a stirrer, a thermometer and a condenser to carry out the polymerization reaction;

[0081] Wherein, the material that participates in polymerization reaction is:

[0082] Methacrylic acid (monomer containing acidic functional group) 89.0 parts by mass

[0083] 5.5 parts by mass of methacrylamide (unsaturated amide)

[0084] 1.5 parts by mass of 2,2,2-trifluoroethyl methacrylate (unsaturated fluorinated carboxylic acid alkyl ester)

[0085] 2.0 parts of 1-vinyl-3-butylimidazolium hexafluorophosphate

[0086] Sodium dodecylphenyl ether sulfonate (surfactant) 1.5 parts by mass

[0087] Potassium persulfate (initiator) 0.5 parts by mass

[0088] 150 parts by mass of deionized water;

[0089] 2. After fully stirring, heat to 75°C to initiate polymerization, stop the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com