Negative electrode binder and application thereof

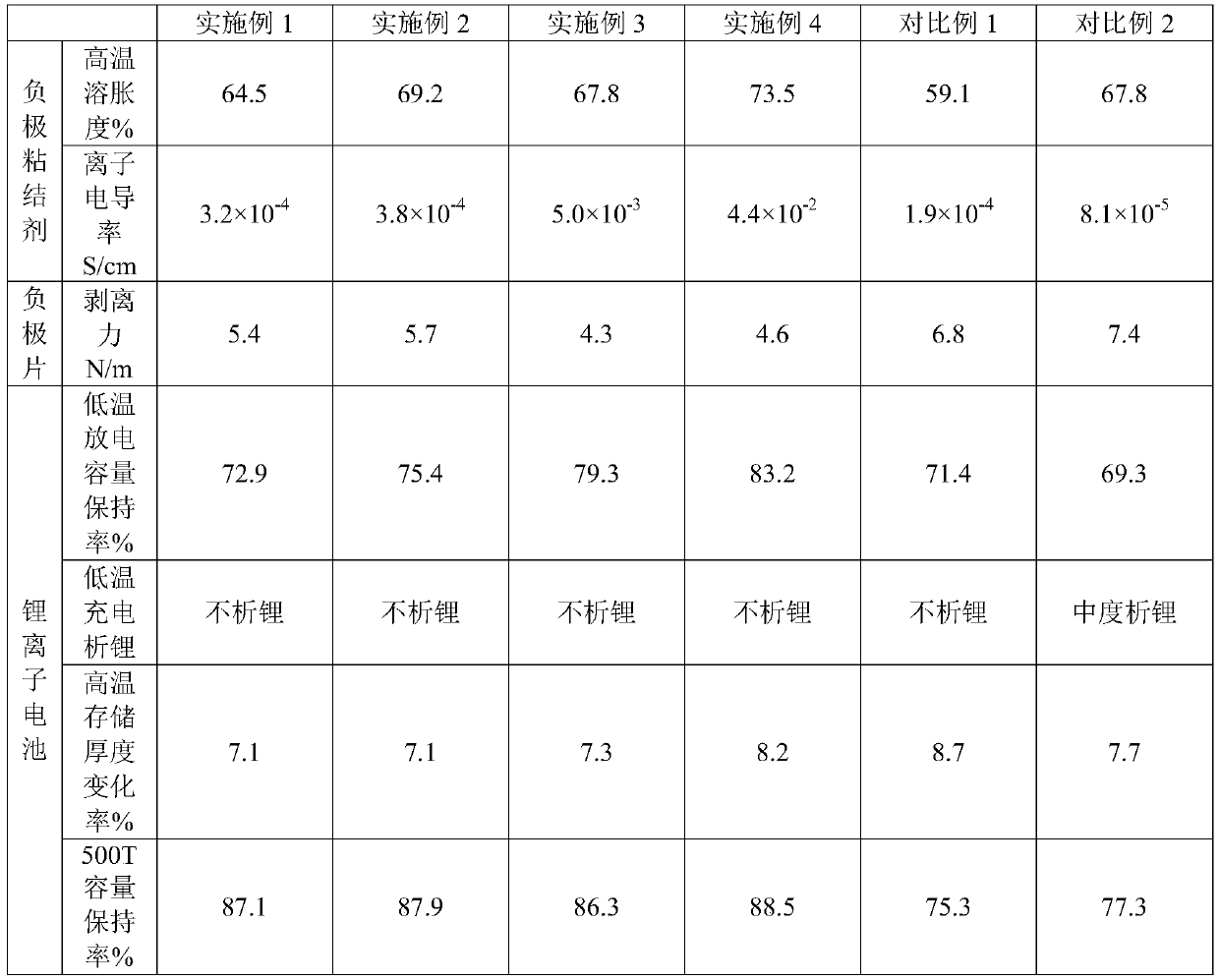

A binder and negative electrode technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problem of no obvious improvement in electrical performance, achieve high-temperature storage performance and high-temperature stability performance, bonding performance and anti-expansion Effects of performance improvement and safety enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

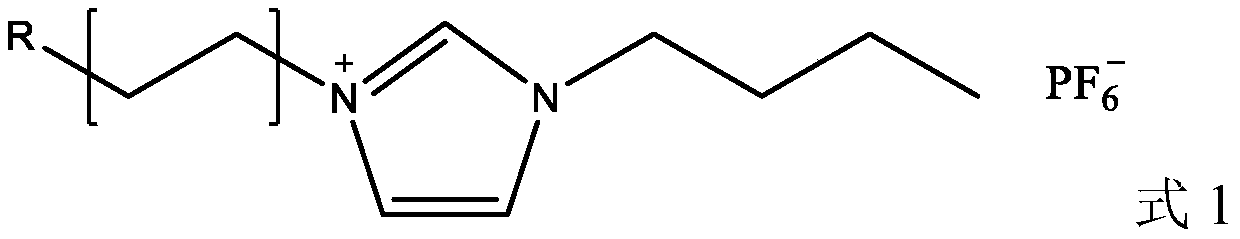

[0052] The preparation method of the aforesaid negative electrode binder of the present invention comprises: heating the system containing unsaturated monomer, 1-vinyl-3-butylimidazole hexafluorophosphate, initiator and surfactant to carry out polymerization reaction, polymerization reaction After the completion, adjust the pH of the reaction system to 6-8 to obtain the negative electrode binder.

[0053] The specific process parameters of the above preparation method and the selection of reactants can be the same as those mentioned above, and will not be repeated here.

[0054] The second aspect of the present invention is to provide a negative electrode sheet, which includes the negative electrode binder of the aforementioned first aspect.

[0055] The negative electrode sheet includes a negative electrode current collector and a negative electrode material coated on the surface of the current collector.

[0056] Specifically, during operation, disperse the negative electro...

Embodiment 1

[0067] The preparation method of the negative electrode binder of the present embodiment comprises:

[0068] 1. Put the materials participating in the polymerization reaction into a reaction vessel equipped with a stirrer, a thermometer and a condenser to carry out the polymerization reaction;

[0069] Wherein, the material that participates in polymerization reaction is:

[0070] Methacrylic acid (monomer containing acidic functional group) 89.5 parts by mass

[0071] 5.5 parts by mass of methacrylamide (unsaturated amide)

[0072] 1.5 parts by mass of 2,2,2-trifluoroethyl methacrylate (unsaturated fluorinated carboxylic acid alkyl ester)

[0073] 1.5 parts of 1-vinyl-3-butylimidazolium hexafluorophosphate

[0074] Sodium dodecylphenyl ether sulfonate (surfactant) 1.5 parts by mass

[0075] Potassium persulfate (initiator) 0.5 parts by mass

[0076] 150 parts by mass of deionized water;

[0077] 2. After fully stirring, heat to 75°C to initiate polymerization, stop the ...

Embodiment 2

[0079] The preparation method of the negative electrode binder of the present embodiment comprises:

[0080] 1. Put the materials participating in the polymerization reaction into a reaction vessel equipped with a stirrer, a thermometer and a condenser to carry out the polymerization reaction;

[0081] Wherein, the material that participates in polymerization reaction is:

[0082] Methacrylic acid (monomer containing acidic functional group) 89.0 parts by mass

[0083] 5.5 parts by mass of methacrylamide (unsaturated amide)

[0084] 1.5 parts by mass of 2,2,2-trifluoroethyl methacrylate (unsaturated fluorinated carboxylic acid alkyl ester)

[0085] 2.0 parts of 1-vinyl-3-butylimidazolium hexafluorophosphate

[0086] Sodium dodecylphenyl ether sulfonate (surfactant) 1.5 parts by mass

[0087] Potassium persulfate (initiator) 0.5 parts by mass

[0088] 150 parts by mass of deionized water;

[0089] 2. After fully stirring, heat to 75°C to initiate polymerization, stop the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com