General formula compound and organic electroluminescent device

A general formula compound, organic technology, applied in the field of organic compounds, can solve the problems of high driving voltage, unfavorable carrier injection and transport balance, lack of host materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

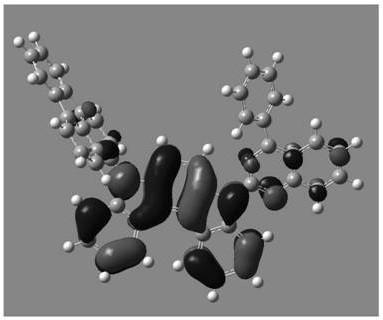

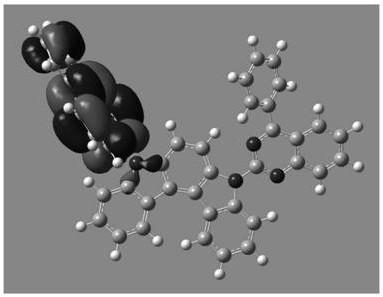

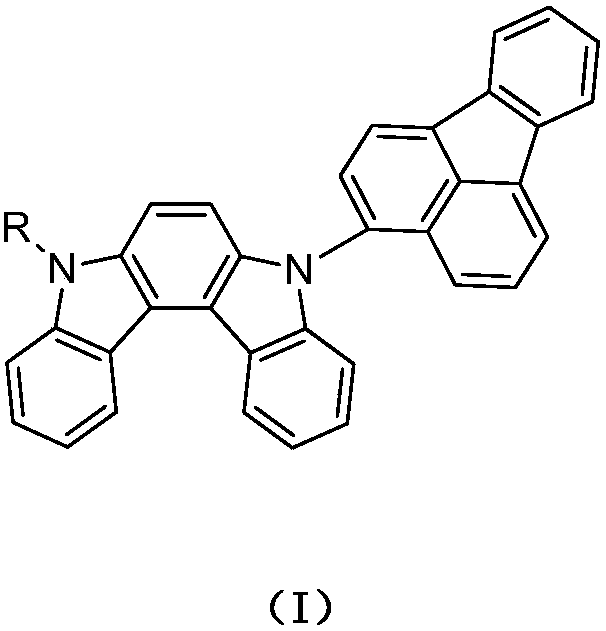

Image

Examples

Synthetic example 1

[0060] Synthesis Example 1: Synthesis of Intermediate M1

[0061]

[0062] In a 250ml three-necked flask, add 1.0g of compound A, 1.2g of compound B, Pd 2 (dba) 3 0.04g, 0.75g of sodium tert-butoxide, 0.02g of tri-tert-butylphosphine tetrafluoroborate and 30ml of xylene, pump nitrogen gas three times, heat up to reflux temperature under the protection of nitrogen gas, and cool down to room temperature after reacting overnight. Diluted with toluene, passed through a silica gel column, and recrystallized with toluene to obtain 1.4 g of a yellow solid with a yield of 80%. MS (m / e): 456, 1 H NMR (300MHz, CDCl 3 ): 8.56(1H), 8.43(2H), 8.11(2H), 8.13(1H), 8.00(2H), 7.95(1H), 7.90(1H), 7.64(2H), 7.61(2H), 7.57(1H ), 7.34(1H), 7.32(1H), 7.30(1H), 7.28(1H), elemental analysis: C(89.5%), N(6.2%), H(4.3%).

Synthetic example 2

[0063] Synthesis Example 2: Synthesis of Compound P1

[0064]

[0065] Into a 250ml three-necked flask, add 1.0g of compound M1, 0.58g of compound C, 0.91g of potassium carbonate and 30ml of DMF, pump nitrogen three times, raise the temperature to 130°C under the protection of nitrogen, and react overnight, then cool down to room temperature, and the reaction solution Pour into water to precipitate a precipitate, filter the precipitate, dissolve the filter cake in toluene, pass through a silica gel column, and recrystallize with toluene to obtain 1.2 g of a bright yellow solid, MS (m / e): 660, yield 80%. MS (m / e): 456, 1 H NMR (300MHz, CDCl 3 ): 8.56(2H), 8.43(2H), 8.16(1H), 8.11(2H), 8.06(2H), 7.95(4H), 7.80(4H), 7.64(1H), 7.61(2H), 7.52(2H ), 7.42(1H), 7.34(2H), 7.32(1H), 7.28(2H), elemental analysis: C(87.3%), N(8.5%), H(4.2%).

Synthetic example 3

[0066] Synthesis Example 3: Synthesis of Compound P11

[0067]

[0068] The preparation method was the same as P1, except that compound C was replaced by compound D to obtain 1.0 g of a bright yellow solid product with a yield of 81%. MS(m / s): 584, 1 H NMR (300MHz, CDCl 3 ): 9.75(1H), 8.56(2H), 8.43(2H), 8.16(1H), 8.11(2H), 8.06(2H), 7.95(4H), 7.80(2H), 7.64(1H), 7.61(2H ), 7.34(2H), 7.32(1H), 7.28(2H), elemental analysis: C(86.3%), N(9.6%), H(4.1%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com