Functional packaging film and production process thereof

A packaging film and functional technology, applied in the field of functional packaging film and its production process, can solve the problems of unsatisfactory antibacterial properties and ventilation effects, and achieve the advantages of avoiding unsatisfactory antibacterial properties and ventilation effects, good compatibility and formulation. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

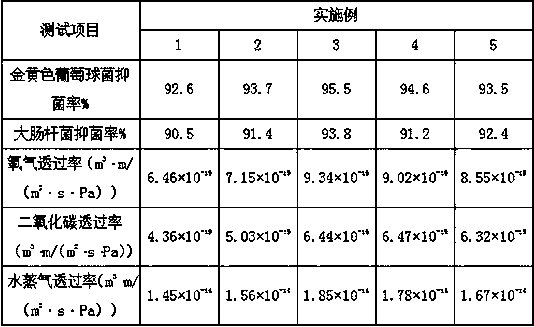

Examples

Embodiment 1

[0022] A functional packaging film proposed by the present invention comprises the following raw materials in parts by weight: 80 parts of polyethylene resin, 4 parts of carboxymethyl chitosan, 0.4 part of diacetyl tartrate mono-diglyceride, 3 parts of silicon dioxide, octyl 0.3 part of sodium starch alkenyl succinate, 0.025 part of antioxidant and 0.1 part of benzoic acid; the antioxidant is a compound of α-tocopherol and antioxidant 618, and α-tocopherol and antioxidant 618 The mass ratio is 0.5:1.

[0023] The production process of the functional packaging film comprises the following steps:

[0024] S1, by weight, weigh 80 parts of polyethylene resin, 4 parts of carboxymethyl chitosan, 0.4 part of diacetyl tartrate mono-diglyceride, 3 parts of silicon dioxide, 0.3 part of sodium starch octenyl succinate, anti- 0.025 parts of oxygen agent and 0.1 part of benzoic acid are set aside;

[0025] S2. Preheat the weighed polyethylene resin at 50°C for 40 minutes, then raise the ...

Embodiment 2

[0029] A functional packaging film proposed by the present invention comprises the following raw materials in parts by weight: 82 parts of polyethylene resin, 6 parts of carboxymethyl chitosan, 0.5 part of diacetyl tartrate mono-diglyceride, 3.6 parts of silicon dioxide, octyl 0.35 part of sodium starch alkenyl succinate, 0.03 part of antioxidant and 0.13 part of benzoic acid; the antioxidant is a compound of α-tocopherol and antioxidant 618, and α-tocopherol and antioxidant 618 The mass ratio is 0.6:1.

[0030] The production process of the functional packaging film comprises the following steps:

[0031] S1. By weight, weigh 82 parts of polyethylene resin, 6 parts of carboxymethyl chitosan, 0.5 part of diacetyl tartrate mono-diglyceride, 3.6 parts of silicon dioxide, 0.35 part of sodium starch octenyl succinate, 0.03 part of oxygen agent and 0.13 part of benzoic acid are set aside;

[0032] S2. Preheat the weighed polyethylene resin at 50°C for 40 minutes, then raise the t...

Embodiment 3

[0036] A functional packaging film proposed by the present invention comprises the following raw materials in parts by weight: 90 parts of polyethylene resin, 9 parts of carboxymethyl chitosan, 0.6 part of diacetyl tartrate mono-diglyceride, 4.5 parts of silicon dioxide, octyl 0.55 part of sodium starch alkenyl succinate, 0.04 part of antioxidant and 0.2 part of benzoic acid; the antioxidant is a compound of α-tocopherol and antioxidant 618, and α-tocopherol and antioxidant 618 The mass ratio is 0.75:1.

[0037] The production process of the functional packaging film comprises the following steps:

[0038] S1. By weight, weigh 90 parts of polyethylene resin, 9 parts of carboxymethyl chitosan, 0.6 part of diacetyl tartrate mono-diglyceride, 4.5 parts of silicon dioxide, 0.55 part of sodium starch octenyl succinate, 0.04 part of oxygen agent and 0.2 part of benzoic acid are set aside;

[0039]S2. Preheat the weighed polyethylene resin at 55°C for 30 minutes, then raise the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com