Polyurethane adhesive liquid specifically applicable to production of popcorn-like shoe material and reaction kettle thereof

A polyurethane and popcorn technology, applied in the field of polyurethane glue, can solve the problems of unfavorable popcorn shoe material production, poor heat resistance, etc., and achieve the effects of small occupied space, good stirring effect, and improved mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

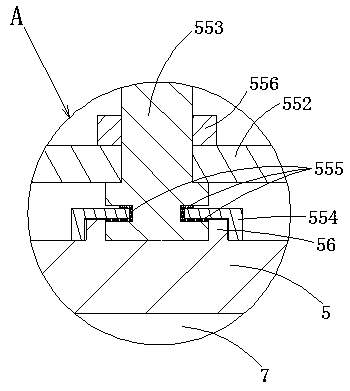

Image

Examples

preparation example Construction

[0027]The preparation process of the glue is as follows: firstly add trimethylolethane, ethyl diisocyanate cyclohexane, acetone, dicarboxymethyl propionic acid, and monoethanolamine into the reaction kettle in sequence, and continue for 28-42r / s Stir at a high speed for 3 to 5 minutes to obtain a slurry; then add alkylene ether, acetyl tributyl citrate, ammonium polyacrylate, methyl tin mercaptide, isopropyl titanate, and titanium dioxide to the slurry in the reactor in sequence , and continue to stir at a speed of 15-18r / s for 15-25 minutes, making the state of each component of the slurry more stable and relatively dispersed, improving the thermal stability of the slurry and reducing the impact of light; finally, the propane Add diamine, diethylthiotoluenediamine, and diphenylguanidine into the reaction kettle in sequence, and continue to stir at a low speed of 6-9r / s for 2-6 hours to extend the chain and vulcanize to obtain the polyurethane rubber. liquid. The heat resista...

Embodiment approach 1

[0035] The raw materials for the preparation of the glue of the present embodiment consist of the following components in parts by weight: 42 parts of trimethylolethane, 24 parts of ethyl diisocyanate cyclohexane, 5 parts of diphenylguanidine, dicarboxymethyl 10 parts of propionic acid, 4 parts of monoethanolamine, 5 parts of ammonium polyacrylate, 6 parts of propylene diamine, 1 part of diethylthiotoluenediamine, 4 parts of alkylene ether, 19 parts of acetone, triacetyl citrate 2 parts of butyl ester, 1 part of methyl tin mercaptide, 0.8 part of isopropyl titanate, and 0.2 part of titanium dioxide.

Embodiment approach 2

[0037] The raw materials for the preparation of the glue of the present embodiment consist of the following components in parts by weight: 40 parts of trimethylolethane, 26 parts of diisocyanate ethylcyclohexane, 4 parts of diphenylguanidine, dicarboxymethyl 10 parts of propionic acid, 5 parts of monoethanolamine, 5 parts of ammonium polyacrylate, 6 parts of propylene diamine, 1.8 parts of diethylthiotoluenediamine, 5 parts of alkylene ether, 18 parts of acetone, triacetyl citrate 2 parts of butyl ester, 1.2 parts of methyl tin mercaptide, 0.8 parts of isopropyl titanate, and 0.2 parts of titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com