Yellow and green light long-afterglow material with improvement on afterglow performance by adding boron as well as preparation method of the material

A technology of long afterglow materials and yellow-green light, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high sintering process requirements for transparent ceramic materials and the inability to complete common experimental conditions, and achieve wide excitation and emission ranges and low equipment costs. Pollution, effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

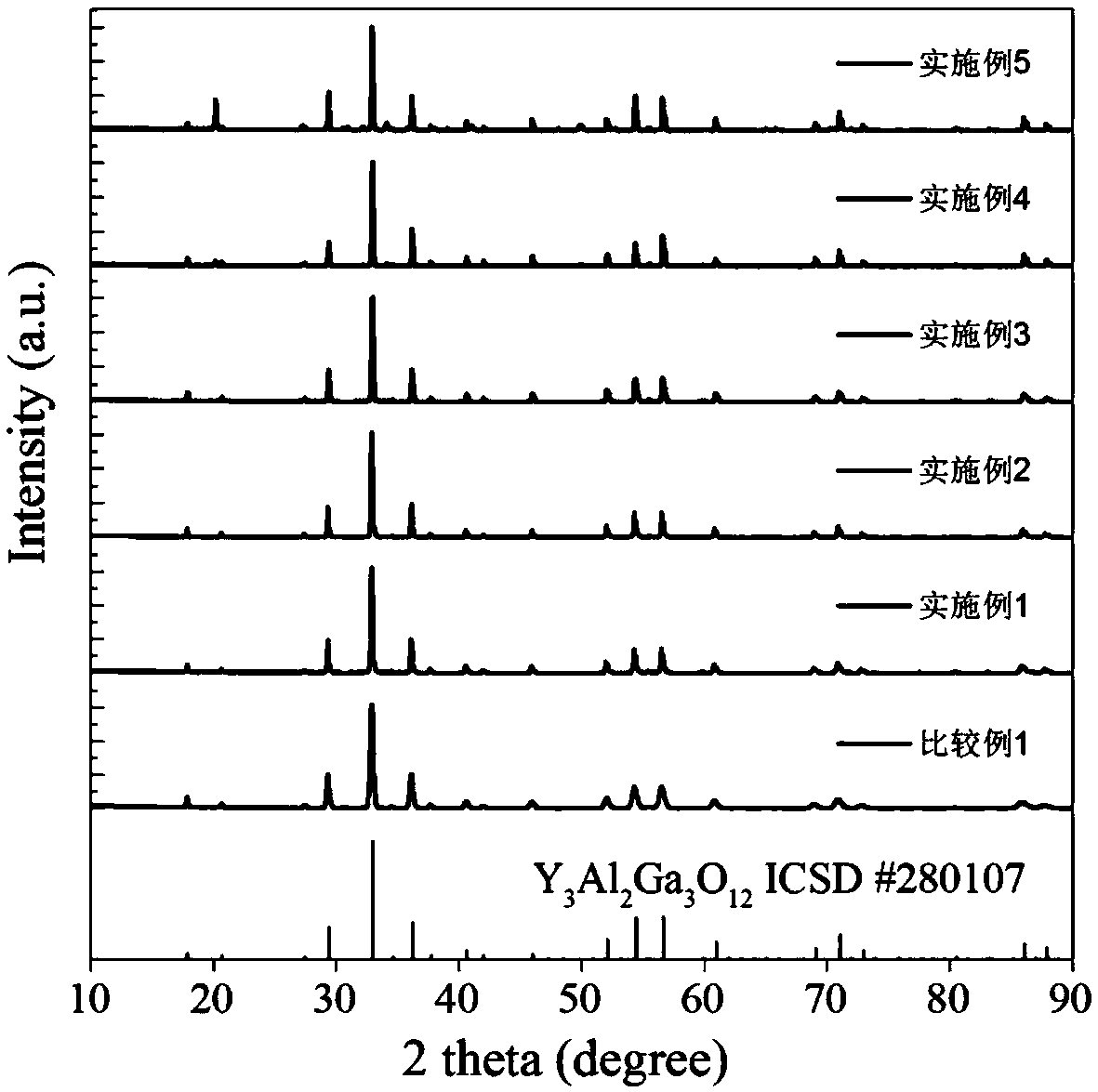

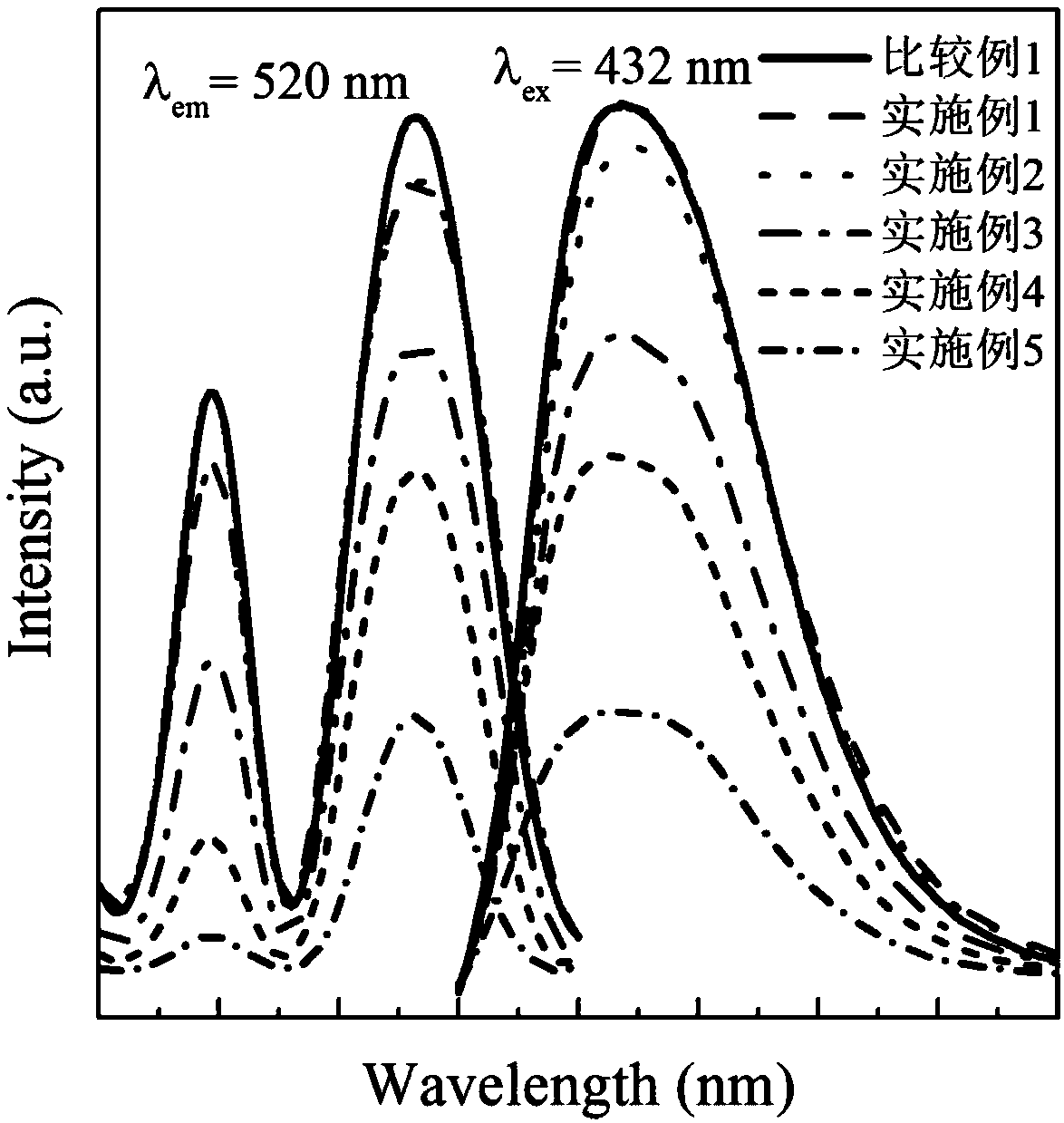

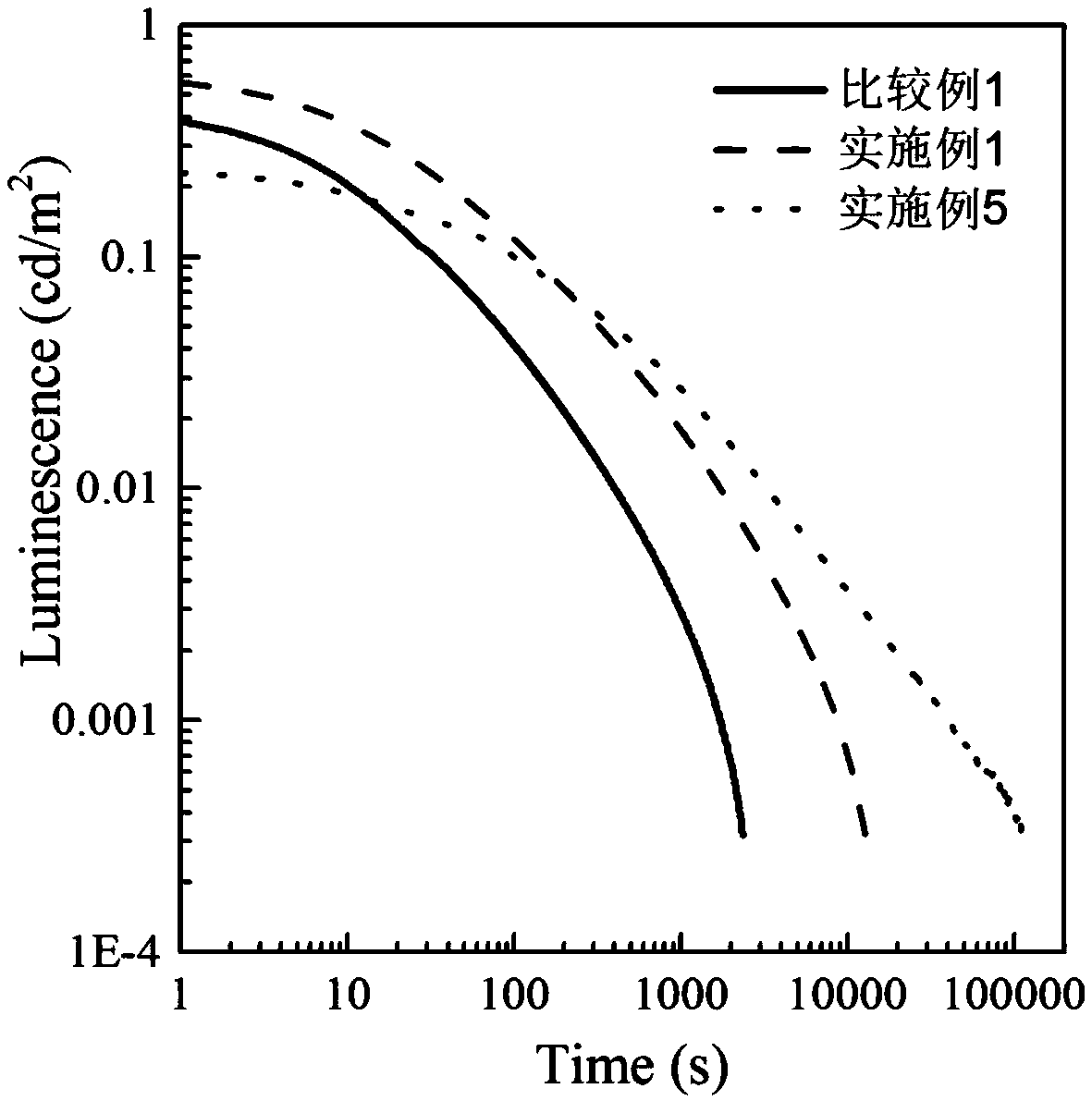

Embodiment 1

[0027] The composition coefficients of the long-lasting luminescent material are a=0.015, b=0.003, and x=0.005. The raw materials are weighed according to the chemical molar ratio and mixed evenly, and calcined in air, reducing gas or high-pressure inert atmosphere at a temperature of 1400-1600°C for 4 hours. The fired samples were ground and pulverized, then cleaned with deionized water, ethanol and dilute acid, and finally dried at 60°C. Measure emission spectrum, photoexcitation spectrum, afterglow decay curve and thermal excitation spectrum.

Embodiment 2

[0029] The composition coefficients of the long-lasting luminescent material are a=0.015, b=0.003, and x=0.01. The raw materials are weighed according to the chemical molar ratio and mixed evenly, and calcined in air, reducing gas or high-pressure inert atmosphere at a temperature of 1400-1600°C for 4 hours. The fired samples were ground and pulverized, then cleaned with deionized water, ethanol and dilute acid, and finally dried at 60°C. Measure emission spectrum, photoexcitation spectrum, afterglow decay curve and thermal excitation spectrum.

Embodiment 3

[0031] The composition coefficients of the long-lasting luminescent material are a=0.015, b=0.003, and x=0.02. The raw materials are weighed according to the chemical molar ratio and mixed evenly, and calcined in air, reducing gas or high-pressure inert atmosphere at a temperature of 1400-1600°C for 4 hours. The fired samples were ground and pulverized, then cleaned with deionized water, ethanol and dilute acid, and finally dried at 60°C. Measure emission spectrum, photoexcitation spectrum, afterglow decay curve and thermal excitation spectrum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com