Extraction separation method of rare earth element

A separation method and rare earth element technology, which are applied in the field of rare earth element separation, can solve the problems of unsolved problems such as the decrease of the extraction capacity of the composite extractant recycling extractant, affecting the application of green extraction technology, etc., so as to reduce the cost of rare earth separation, improve the extraction capacity and Separation capacity, effect of reducing acid and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

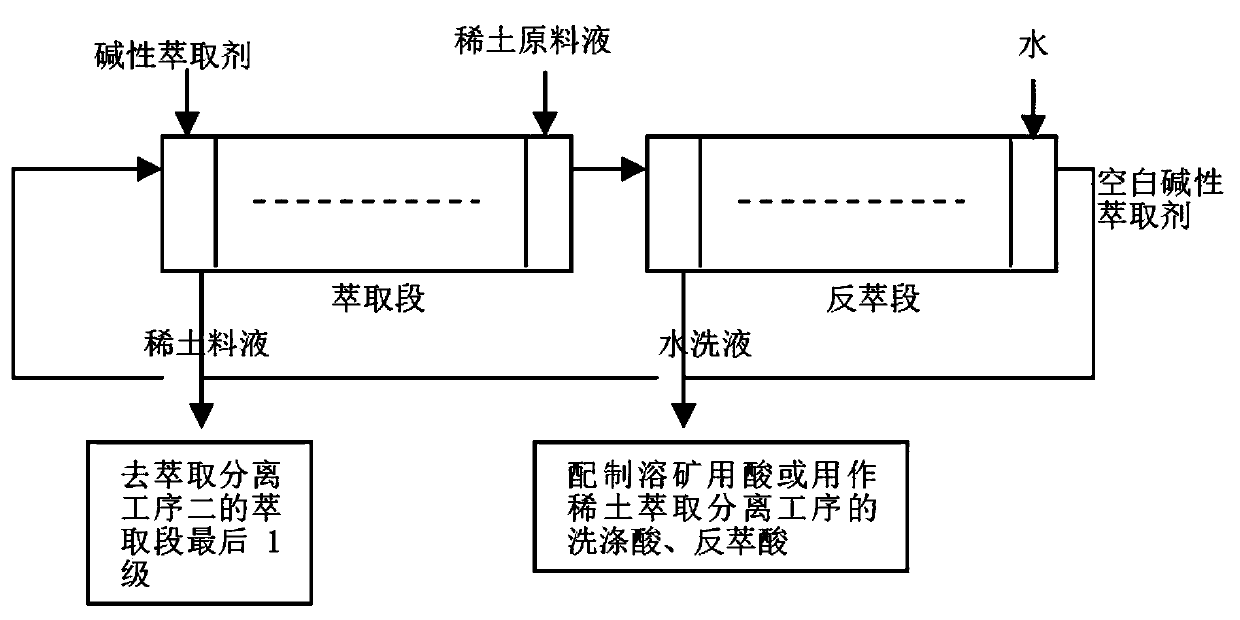

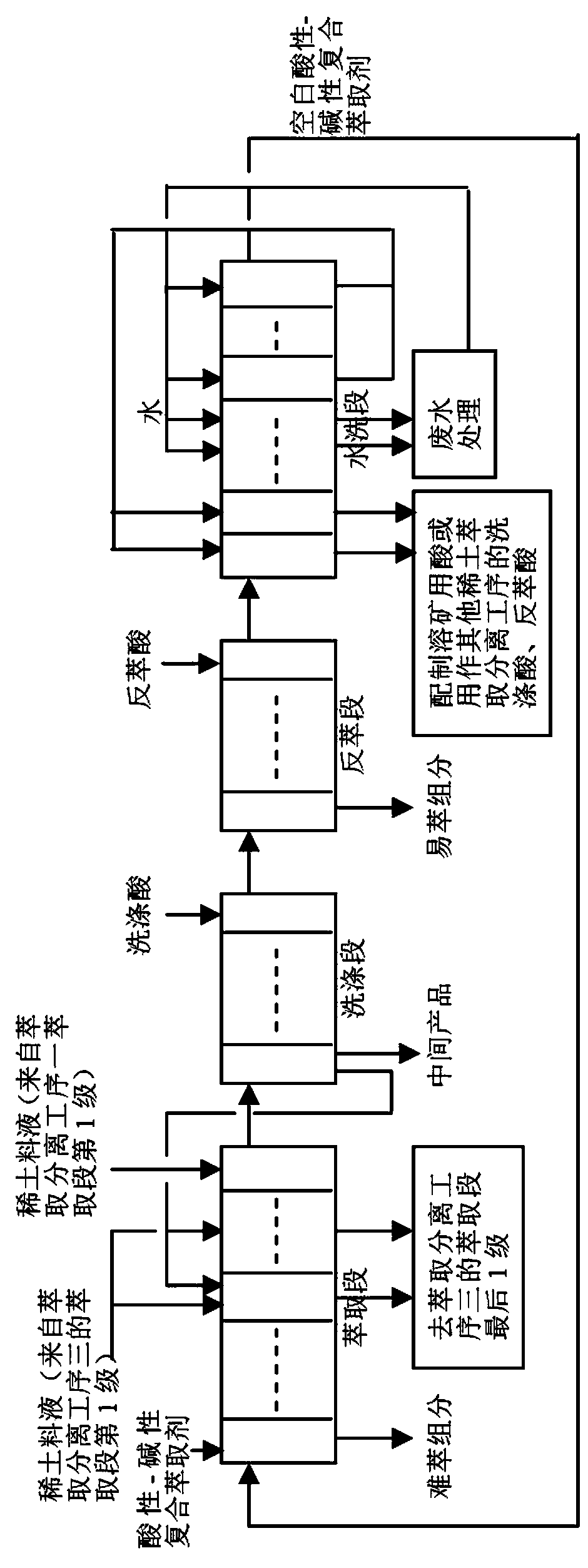

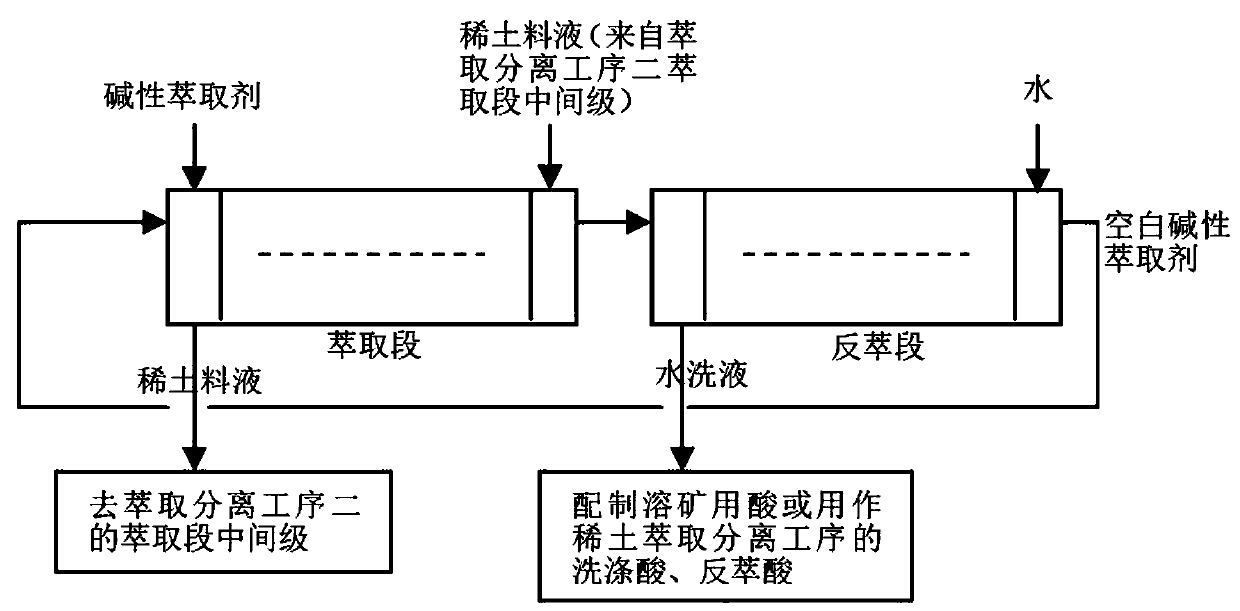

[0041] refer to Figure 1-3 , (1) Send the rare earth raw material solution containing La, Ce, Pr, and Nd (the rare earth concentration is 1.3mol / L, the hydrogen ion concentration is 0.7mol / L) into the first stage from the bottom of the extraction section in the extraction and separation process one, The basic extractant (composed of 15% trioctylamine, 30% 2-octanol and 55% n-hexane) is sent to the first stage of the extraction section, and the organic phase after the 4th stage extraction flows into the first stage of the stripping section, The water is sent to the penultimate first stage of the stripping section, and the organic phase is returned to the first stage of the extraction section after 6-stage stripping for reuse; the water phase discharged from the first stage of the extraction section is sent to the second extraction and separation process;

[0042] (2) Send the acidic-alkaline compound extractant (composed of 20% 2-ethylhexylphosphonic acid mono-2-ethylhexyl est...

Embodiment 2

[0050] refer to Figure 1-3 , (1) Send the rare earth raw material solution containing La and Ce (the concentration of rare earth is 1.1mol / L, the concentration of hydrogen ion is 1.0mol / L) into the reciprocal first stage of the extraction section in the extraction and separation process 1, and the alkaline extraction The agent (composed of 30% primary amine, 30% tributyl phosphate and 40% sulfonated kerosene) is sent to the first stage of the extraction section, and the organic phase after five-stage extraction flows into the first stage of the stripping section, and the water It is sent to the penultimate first stage of the stripping section, and the organic phase is returned to the first stage of the extraction section for reuse after 7-stage stripping; the aqueous phase discharged from the first stage of the extraction section is sent to the second extraction and separation process;

[0051] (2) Send the acidic-alkaline compound extractant (composed of 45% 2-ethylhexylphos...

Embodiment 3

[0059] refer to Figure 2-3 , (1) Acidic-alkaline composite extractant (composed of 15% bis(2,4,4-trimethylpentyl)phosphonic acid, 30% trioctylamine, 30% n-heptanol and 25% sulfonated kerosene ) into the first stage of the extraction section in the second extraction and separation process, which will contain 15 kinds of rare earths such as La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y, etc. The elemental hydrochloric acid solution (the rare earth concentration is 1.6mol / L, the hydrogen ion concentration is 0.001mol / L) is sent to the reciprocal first stage of the extraction section in the second extraction and separation process;

[0060] In the process of extraction, the water phase of the penultimate 4th stage of the extraction section in the extraction and separation process 2 is drawn out, sent to the penultimate 1st stage of the extraction section 3 in the extraction and separation process, and flows through the extraction section in the extraction and separati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com