High-performance deformation bamboo tendons and manufacturing technology thereof

A manufacturing process and high-performance technology, applied in the field of high-performance deformed bamboo reinforcement and its manufacturing process, can solve problems such as slippage, reduced mechanical properties of bamboo, and increased brittleness of bamboo, and achieve enhanced dimensional stability and anti-corrosion Ability to improve corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

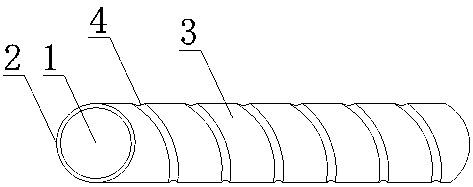

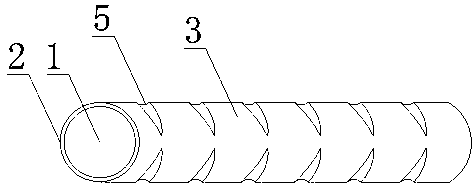

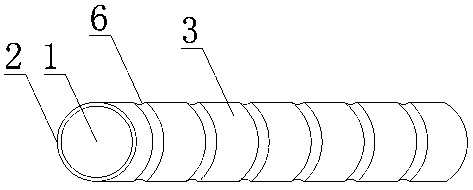

[0036] see Figure 1 to Figure 4 , a kind of high-performance deformed bamboo bar and its manufacturing process, comprising the following steps:

[0037] a. Bamboo pretreatment: Sanding the outer surface of the bamboo (1) to remove the green and yellow of the bamboo, so that the bamboo joints cannot be damaged;

[0038] b. Cutting concave ribs of bamboo: cutting the concave ribs on the outer surface of the bamboo (1) processed in step a, which can be cut into different concave rib forms according to needs;

[0039] c. One-time high-temperature treatment: put the bamboo material (1) treated in step b into a high-temperature box for one-time high-temperature treatment, raise the temperature to 170-200°C at a heating rate of 4-5°C / min, and keep the temperature constant for 3-4h;

[0040] d. One-time s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com