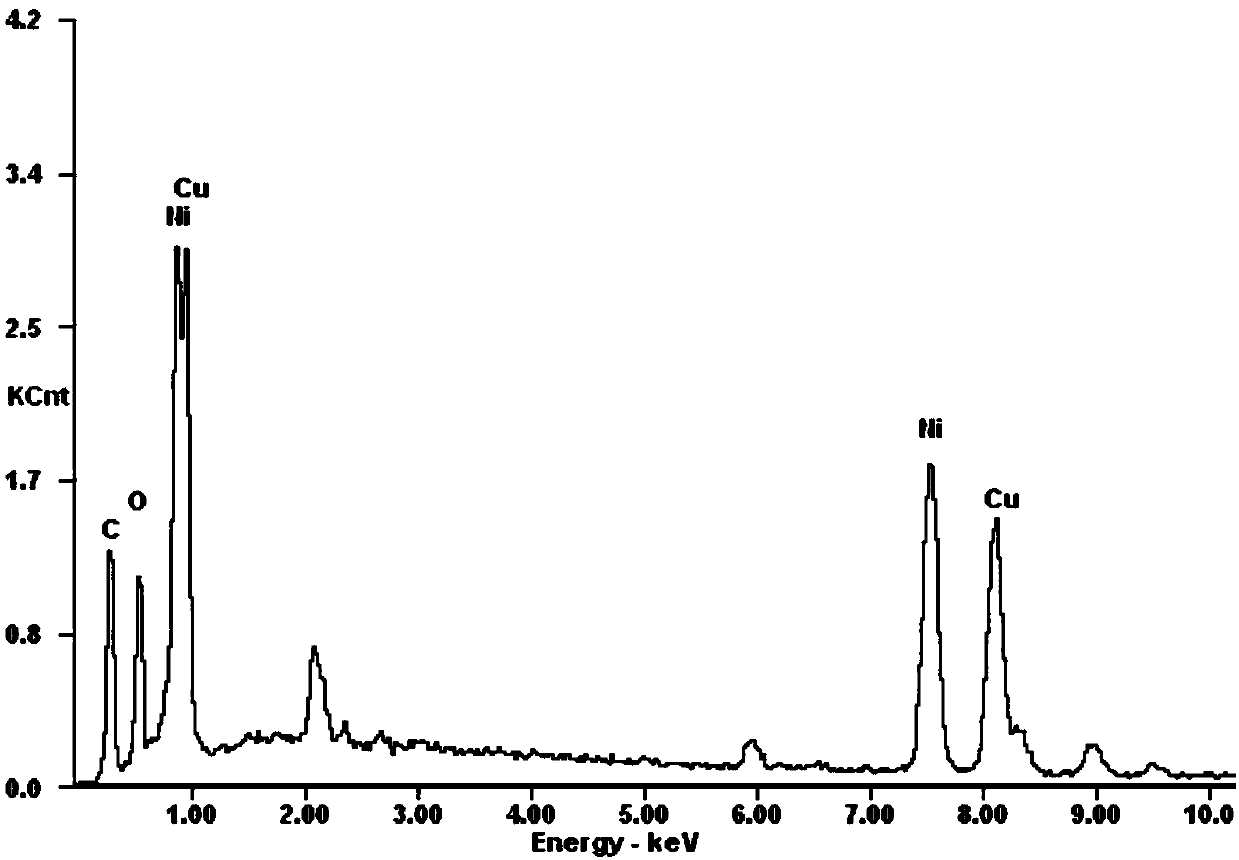

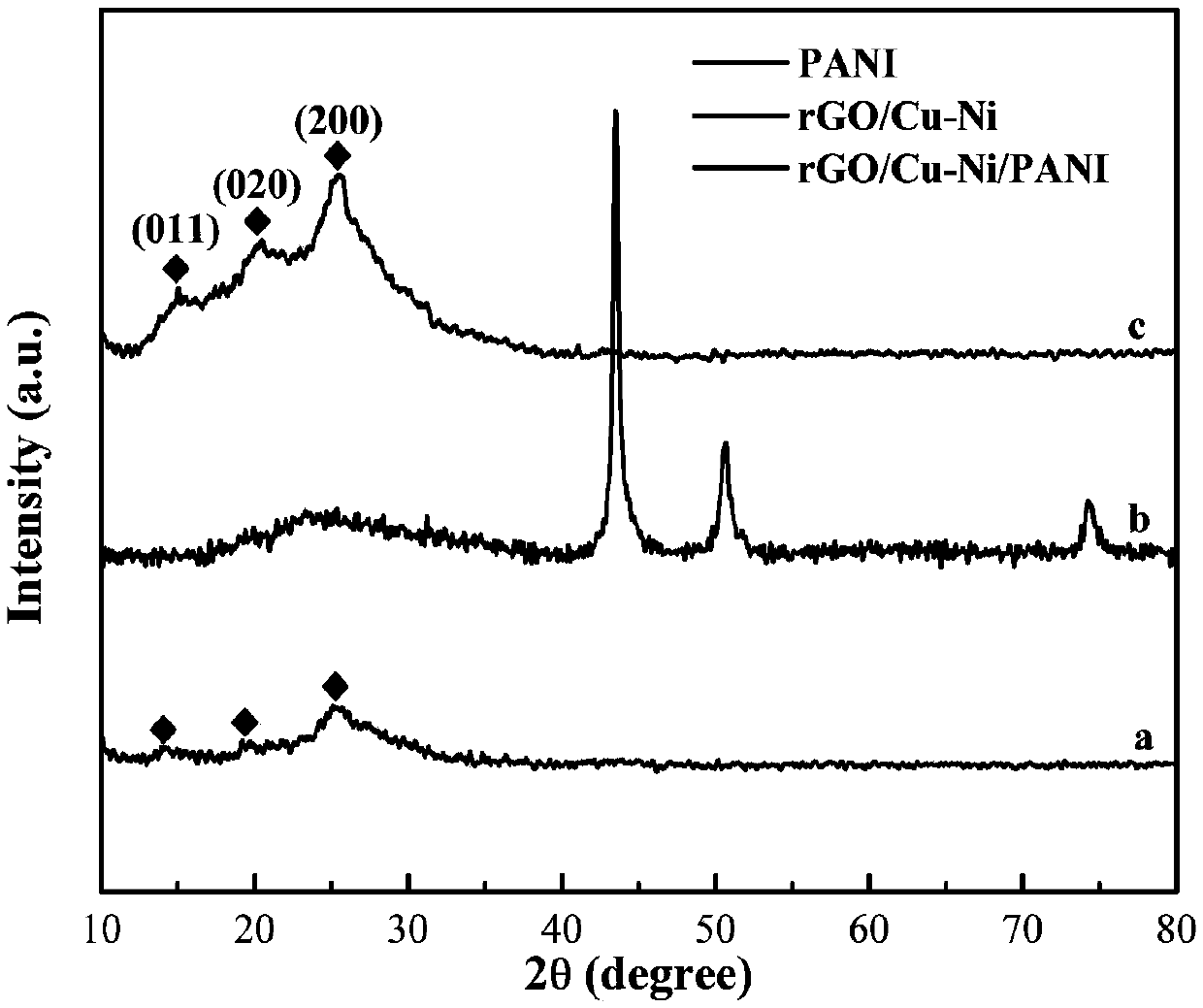

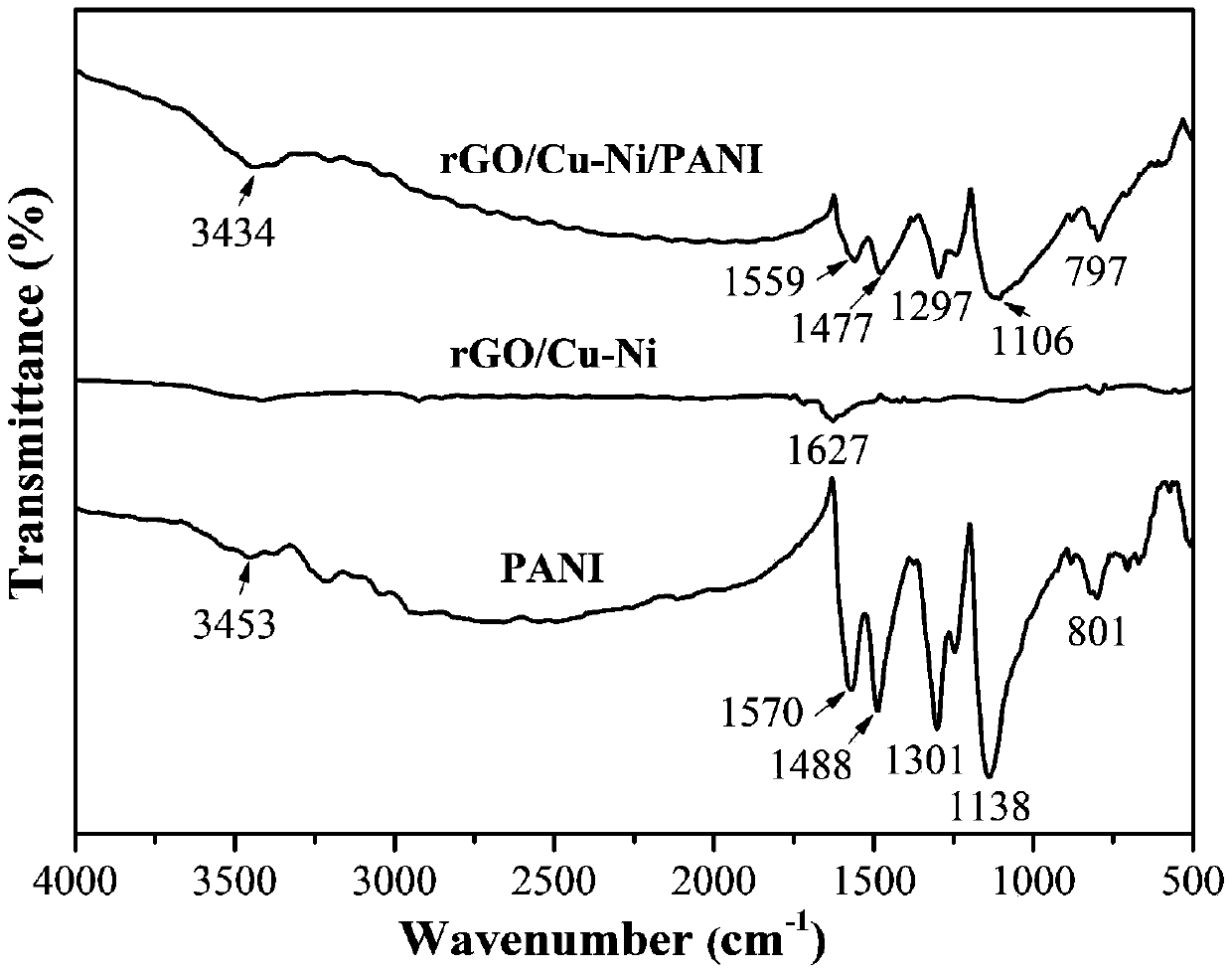

Preparation method for polyaniline-coated graphene loaded copper-nickel solid solution composite material

A composite material and graphene technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of low specific capacitance, achieve good stability and prevent oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the graphene oxide used in the present embodiment is prepared according to the following steps:

[0033] Step 1. Add 2.4g of graphite powder into 100mL of concentrated sulfuric acid, -1 Stir for 30min at the speed of rotation;

[0034] Step 2, then placed in an ice bath, at 100r·s -1 Stir at high speed, add a mixture of 20g potassium permanganate and 3g sodium nitrate within 1 hour, and continue stirring for 2h;

[0035] Step 3. Remove the ice bath, and set the temperature at room temperature at 100r·s -1 Speed continued to stir for 2h;

[0036] Step 4. Place in a water bath at 35°C at 250r·s -1 Stirring at high speed for 12h;

[0037] Step 5, then add 300mL distilled water to dilute, then add 30% hydrogen peroxide solution until golden yellow, then add 10mL dilute hydrochloric acid with a concentration of 1M, centrifuge and pour into a semi-permeable membrane for dialysis (the purpose is to achieve neutrality) , to obtain graphene oxide.

[0038]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com