Pea protein vegan plant-based yoghurt and preparation method thereof

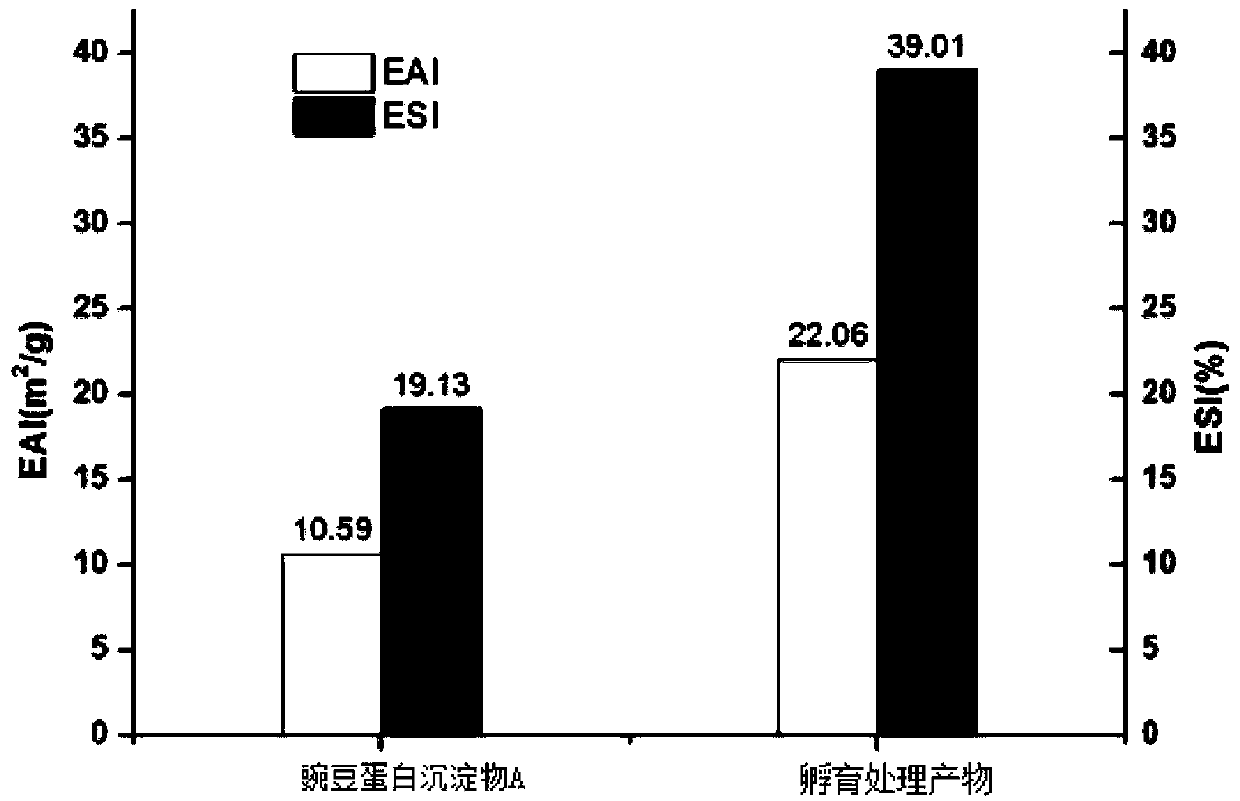

A pea protein, vegan technology, applied in the protein composition of vegetable seeds, dairy products, vegetable protein processing, etc., can solve the problems of faster pH drop, worse water holding capacity, poor taste, etc. Improved solubility, increased added value, good emulsifying activity and emulsifying stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The first aspect of the present disclosure provides a preparation method of pea protein vegan plant-based yoghurt, the method comprising the following steps:

[0045] S1. Grinding the peas and adding water to make a suspension, then adding a medium-temperature α-amylase and heating and stirring to obtain the first material; adding an alkaline regulator to the first material to adjust the pH value to 9-10, Obtaining the second material; performing first-stage centrifugation on the second material and collecting the supernatant, adding an acid regulator to the supernatant to adjust the pH value to 3-5 to obtain a third material; The third material is subjected to second-stage centrifugation and the pea protein precipitate is collected;

[0046] S2. After adding the first pH adjuster to the pea protein precipitate to adjust the pH value to 6.5-7.5, then add anionic polysaccharide and mix evenly and undergo hydration treatment to obtain the fourth material; in the fourth ma...

Embodiment 1

[0062] S1. The yellow dry peas were ground into powder with a cyclone mill, crushed into particles with a particle size of 60 mesh, added deionized water to prepare a suspension, and then added medium-temperature α-amylase Ban480, and heated and stirred at 80°C for 30 minutes to obtain No. One material; after cooling the first material, adding a NaOH solution with a concentration of 1mol / L to the first material to adjust the pH value to 9 to obtain the second material; Carry out the first-stage centrifugation treatment of 30min under the condition and collect the supernatant, add the HCl solution that concentration is 1mol / L in the supernatant and adjust the pH value to be 4.5, obtain the third material; The third material is 4000g relative centrifugal force 1. Carrying out second-stage centrifugation for 30 min at a temperature of 4° C. to collect pea protein precipitates, and freeze-drying to obtain pea protein precipitate A. Wherein, based on the total weight of the first m...

Embodiment 2

[0066] The only difference between Example 2 and Example 1 is that in Example 2: based on the total weight of the first material, the content of peas is 17% by weight, the content of mesophilic α-amylase is 0.5% by weight, step S1 The pea protein precipitate obtained in B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com