Preparation method and application of a heat-induced irreversible composite hydrogel with antibacterial and wound healing functions

A composite hydrogel and wound healing technology, applied in bandages, medical science and other directions, can solve the problems of not being able to take into account the functions of antibacterial and promoting wound healing at the same time, and the single role of wound dressings, achieving high clinical and market application potential, Promotes wound healing and has a strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

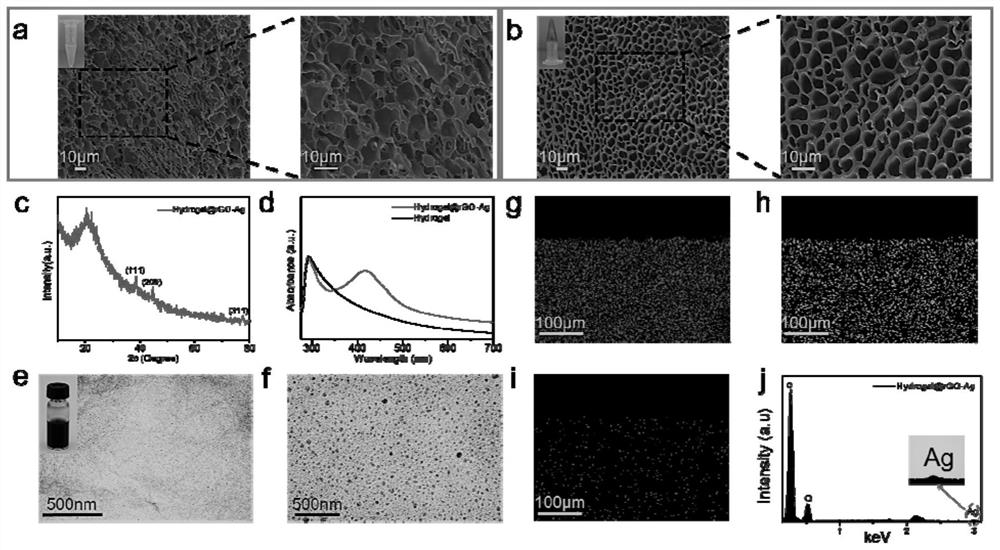

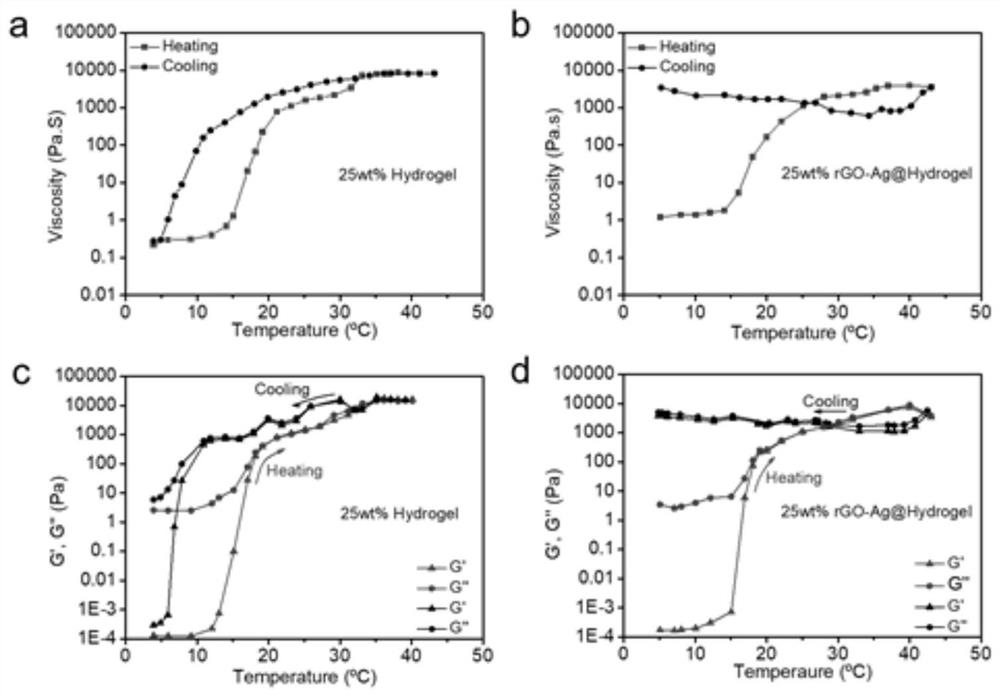

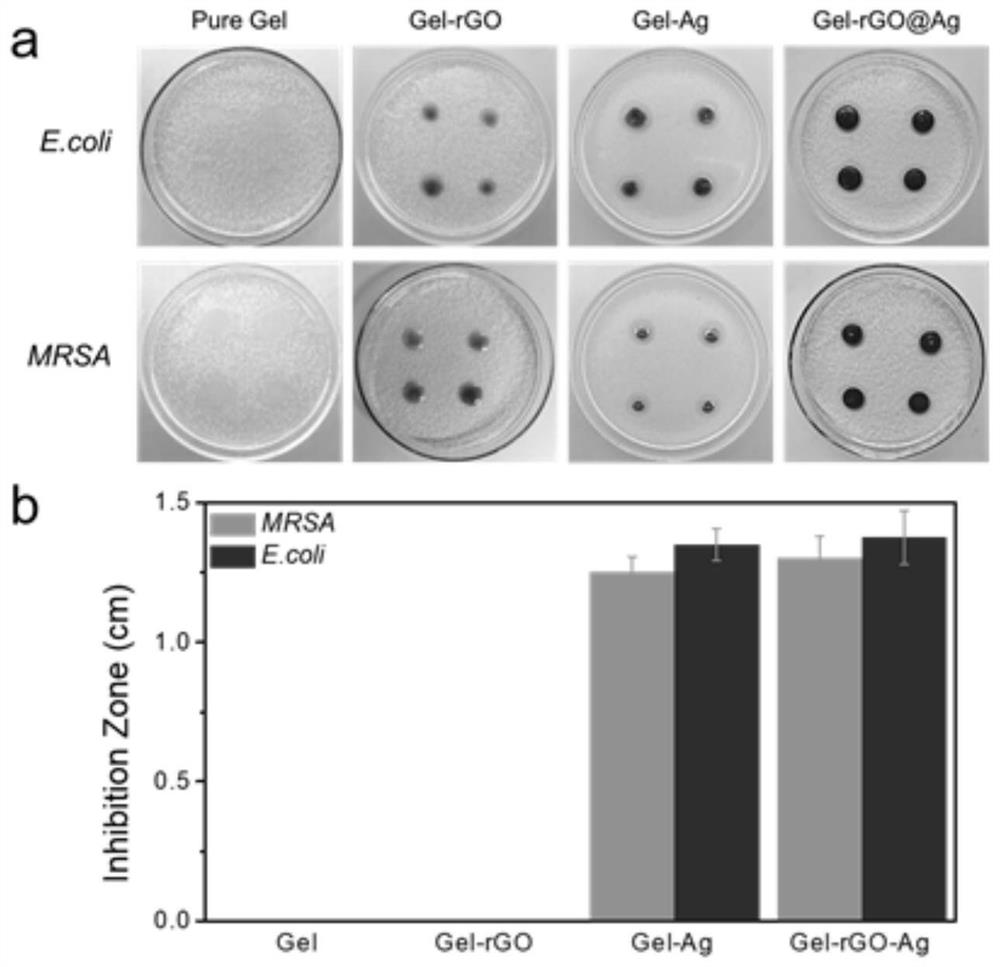

[0025] In this example, the preparation of thermally induced irreversible composite hydrogel is carried out as follows:

[0026] Step 1: Dissolve 15g of polyethylene glycol (Mw=4000) and 1.8g of triethylamine in 150mL of dichloromethane. After argon protection, add 3.4g of 2-bromoisobutyryl bromide, and dissolve the solution in Stir at 0°C for 1 hour, then at room temperature for another 72 hours, the resulting product is separated by aluminum column (eluent is tetrahydrofuran), dialyzed (regenerated cellulose dialysis bag MWCO: 1000D), freeze-dried (lyophilized temperature -60 ℃), obtain atom transfer radical polymerization initiator;

[0027] Step 2: Dissolve 0.2 g of the atom transfer radical polymerization initiator obtained in step 1 in 6 mL of isopropanol / water mixed solvent, put it into a polymerization bottle, and then add 2.5 g of N-isopropylacrylamide, 0.16 g of butyl acrylate and 28.6 mg of cuprous chloride were fully dissolved, protected by argon, and after three ...

Embodiment 2

[0048] In this example, thermally induced irreversible composite hydrogels were prepared according to the following steps:

[0049] Step 1: Dissolve 10g of polyethylene glycol (Mw=4000) and 1g of triethylamine in 150mL of dichloromethane. After passing through argon for protection, add 2g of 2-bromoisobutyryl bromide, and place the solution at 0°C Stirring at low temperature for 1 hour, and then stirring at room temperature for 72 hours, the resulting product was separated by aluminum column (eluent is tetrahydrofuran), dialyzed (regenerated cellulose dialysis bag MWCO: 1000D), lyophilized (lyophilized temperature -60 ° C) Afterwards, obtain atom transfer radical polymerization initiator;

[0050] Step 2: Dissolve 0.2 g of the atom transfer radical polymerization initiator obtained in step 1 in 6 mL of isopropanol / water mixed solvent, put it into a polymerization bottle, and then add 2.5 g of N-propylacrylamide, 0.16g of hydroxyethyl methacrylate and 28.6mg of cuprous chlorid...

Embodiment 3

[0057] In this example, thermally induced irreversible composite hydrogels were prepared according to the following steps:

[0058] Step 1: Dissolve 15g of polyethylene glycol (Mw=4000) and 1.8g of triethylamine in 150mL of dichloromethane. After argon protection, add 3.4g of 2-bromoisobutyryl bromide, and dissolve the solution in Stir at 0°C for 1 hour, then at room temperature for another 72 hours, the resulting product is separated by aluminum column (eluent is tetrahydrofuran), dialyzed (regenerated cellulose dialysis bag MWCO: 1000D), freeze-dried (lyophilized temperature -60 ℃), obtain atom transfer radical polymerization initiator;

[0059]Step 2: Dissolve 0.3 g of the atom transfer radical polymerization initiator obtained in step 1 in 6 mL of isopropanol / water mixed solvent, put it into a polymerization bottle, and then add 3 g of N-isopropylacrylamide, 0.3 g of tert-butyl methacrylate and 50 mg of cuprous chloride were fully dissolved, and protected by argon. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com