Antimicrobial super-smooth material for medical indwelling catheter

A catheter and polyetheramine thiazolidine technology, which is applied in the field of antibacterial and ultra-smooth medical indwelling catheter materials, can solve the problems of inability to guarantee the antibacterial properties of the catheter, poor chemical stability, poor adhesion, etc., and achieves no equipment dependence. High, the preparation method is easy to operate, and the antibacterial properties are evenly distributed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

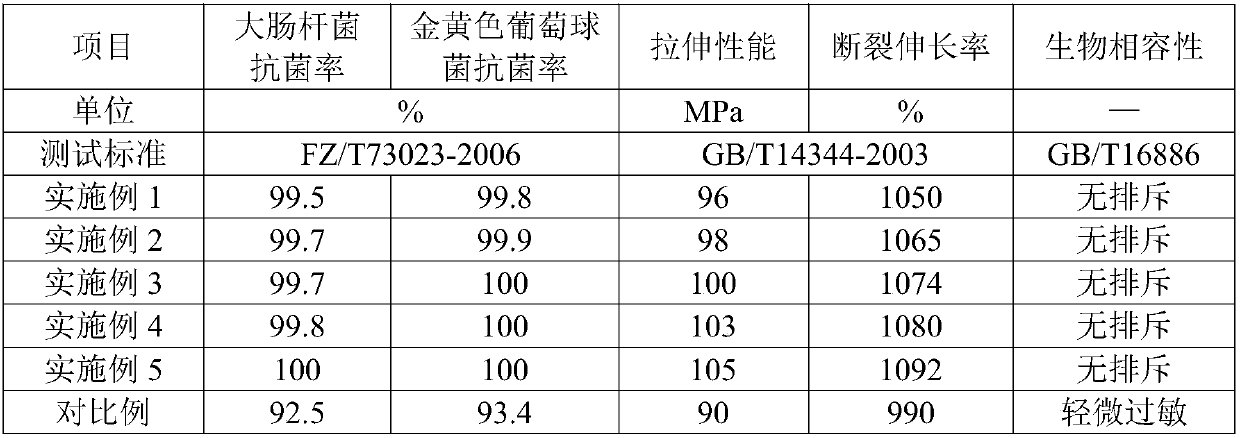

Examples

Embodiment 1

[0029] An antibacterial super-slippery medical indwelling catheter material is made by the following preparation method:

[0030] Ⅰ Preparation of polyetheramine thiazolidine-2,4-dicarboxylic acid amide: 1 kg of thiazolidine-2,4-dicarboxylic acid and polyetheramine in the amount of thiazolidine-2,4-dicarboxylic acid D-2000 was dissolved in 10kg of deionized water and placed in an autoclave. After nitrogen purging, the temperature in the autoclave was kept at 270°C and the pressure at 3.0MPa, and the reaction was stirred for 6 hours, and then within 2 hours Slowly exhaust and reduce the pressure to 1.0MPa, and at the same time raise the temperature in the autoclave to 305°C, then control the temperature between 230°C and stir for 12 hours under nitrogen atmosphere to obtain polyetheraminethiazolidine-2,4- Dicarboxylic acid amides;

[0031] Preparation of polycondensate II: Add 1kg of N,N-propargylaniline and 2,6-bis(4-azidobenzylidene)-4methylcyclohexanone 2.19kg to 10kg of di...

Embodiment 2

[0036] An antibacterial super-slippery medical indwelling catheter material is made by the following preparation method:

[0037] Ⅰ Preparation of polyetheramine thiazolidine-2,4-dicarboxylic acid amide: 1 kg of thiazolidine-2,4-dicarboxylic acid and polyetheramine in the amount of thiazolidine-2,4-dicarboxylic acid D-2000 was dissolved in 11kg of deionized water and placed in a high-pressure reactor. After purging with helium, the temperature in the high-pressure reactor was kept at 280°C and the pressure was kept at 3.5MPa. Slowly exhaust and reduce the pressure to 1.0MPa within hours, and at the same time raise the temperature in the autoclave to 308°C, then under vacuum conditions, control the temperature between 235°C, stir and react for 12.5h to obtain polyetheraminethiazolidine-2 ,4-dicarboxylic acid amide;

[0038] Preparation of polycondensate II: Add 1kg of N,N-propargyl aniline and 2.19kg of 2,6-bis(4-azidobenzylidene)-4 methylcyclohexanone to N,N-dimethyl In 11.5...

Embodiment 3

[0043] An antibacterial super-slippery medical indwelling catheter material is made by the following preparation method:

[0044] Ⅰ Preparation of polyetheramine thiazolidine-2,4-dicarboxylic acid amide: 1 kg of thiazolidine-2,4-dicarboxylic acid and polyetheramine in the amount of thiazolidine-2,4-dicarboxylic acid D-2000 was dissolved in 15kg of deionized water and placed in a high-pressure reactor. After purging with neon gas, the temperature in the high-pressure reactor was kept at 285°C and the pressure was kept at 4.0MPa, and the reaction was stirred for 7 hours, and then 2 hours Slowly exhaust the inside and reduce the pressure to 1.0MPa, and at the same time, raise the temperature in the high-pressure reactor to 310°C, and then control the temperature between 245°C and stir for 13.5 hours under a nitrogen environment to obtain polyetheramine thiazolidine-2, 4-Dicarboxylic acid amide;

[0045] Preparation of polycondensate II: Add 1kg of N,N-propargyl aniline and 2,6-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com